COMMISSIONING

36

3 COMMISSIONING

3.1 Preliminary checks

The rst ignition should be carried out by expert per-

sonnel from an authorised Technical Assistance Service

Centre. Before starting up the boiler, check:

that the data of the supply networks (electricity, wa-

ter, gas) correspond to the label data

that the extraction pipes of the ue gases and the air

suction pipes are working correctly

that conditions for regular maintenance are guaran-

teed if the boiler is placed inside or between items of

furniture

the seal of the fuel adduction system

that the fuel ow rate corresponds to the values re-

quired for the boiler

that the fuel supply system is sized to provide the

correct ow rate to the boiler, and that it has all the

safety and control devices required by current regu-

lations

that the circulator rotates freely because, especially

after long periods of non-use, deposits and/or res-

idue may hamper its free movement (see paragraph

“1.10 Manual circulator reset”)

that there is water in the drain-trap (if not, fill it).

After a long period of non-use or following maintenance

work, at the rst subsequent ignition (before starting

up the appliance) it is vital to ll the condensate collec-

tion drain-trap by pouring about 1 litre of water into the

boiler combustion analysis outlet and check:

- the safety disc is oating

- the water leaving the boiler via the discharge tube is

running off correctly

- the seal on the condensate discharge connection line

is rm.

When the condensate discharge circuit (pipes and drain-

trap) is working properly, the condensate does not ex-

ceed the maximum level (max). The preventive lling of

the drain-trap, and the presence of the safety disc in-

side this element, aims to prevent the ue gases from

escaping into the room.

High efciency mode

The boiler is equipped with an automatic function that

is activated at the rst power supply or after 60 days

of non-use (electrically powered boiler). In this mode

the boiler, for 60 minutes, limits the heating power to a

minimum and the maximum DHW temperature to 55 ° C.

Activating the chimney sweep temporarily disables this

function.

The function is managed by parameter P7.08, which is

set by default to 0 (function not active).

During execution, the function is shown on the display

with the word HEM and, if P1.05 = 1, with the scrolling

message “HIGH EFFICIENCY MODE”.

3.2 Programming the boiler

Turn the main system switch ON.

Open the gas tap to allow fuel to ow.

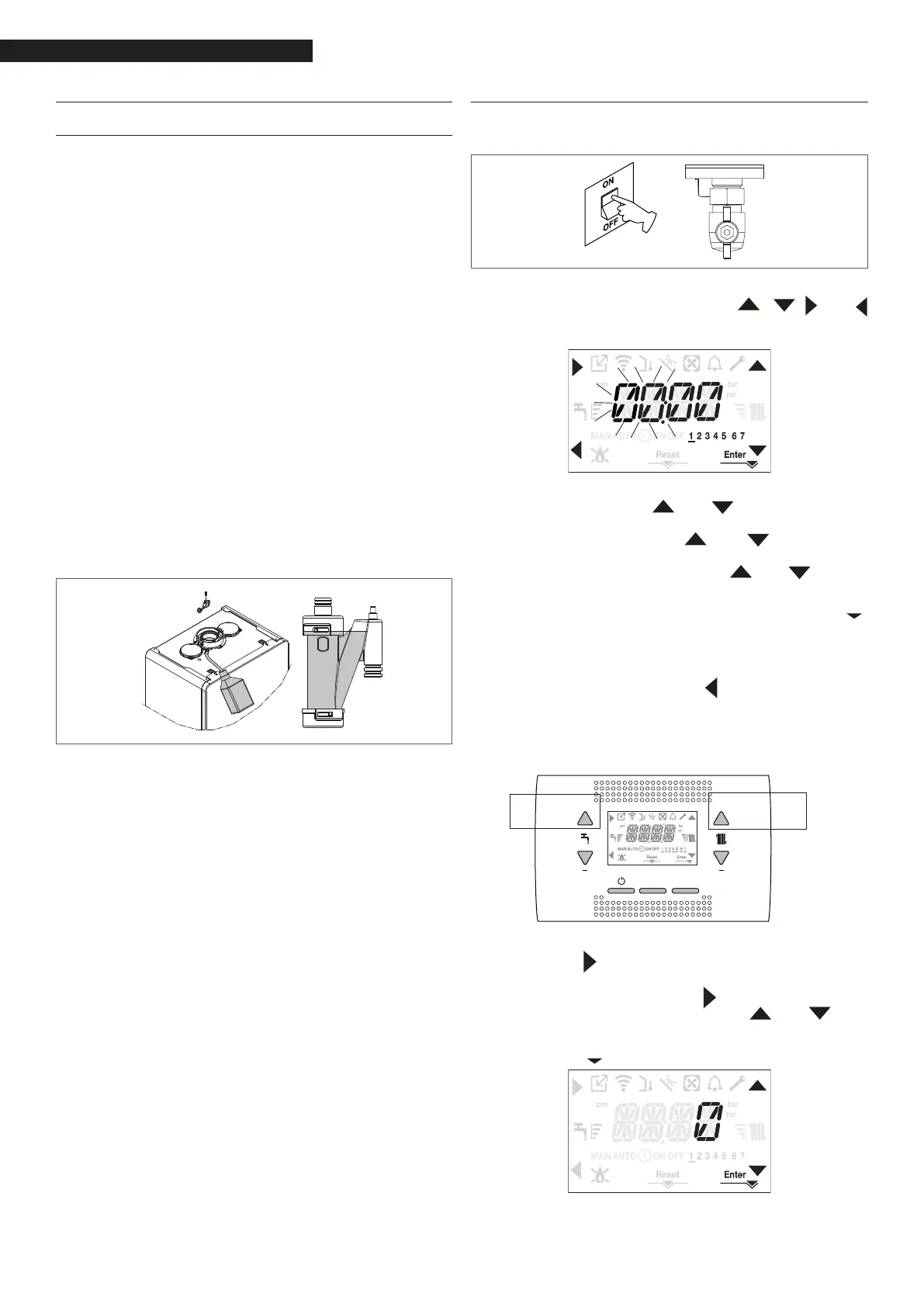

If necessary, the interface goes automatically to the clock

menu. The main

page shows the icons ,

, and

lit up, along with ENTER, and the rst two digits of the

clock (00:00) will be ashing (0.5 sec ON, 0.5 sec OFF).

To set the time and day, proceed as follows:

set the hour using the and arrows, then con-

rm with button A

set the minutes using the and arrows, then

conrm with button A

set the day of the week using the and arrows.

The segment corresponding to the selected day will

ash. Press the MENU button in line with the

icon to conrm the time and day setting. The clock

will ash for 4 seconds, then the main screen will be

displayed again.

to quit the time programming function without saving

the new values, just press the button.

NOTE:

the TIME and DAY settings can be modied at any time

by accessing menu P1, parameter P1.02, or by pressing but-

tons A+C for at least 2 seconds.

A

C

+ +

RESET

MENU

If the language needs to be set, select menu P1 and

conrm with .

Use the arrows to visualise parameter P1.01, then en-

ter the sub-menu by pressing .

Set the required language using the and but-

tons - see “1.13 Structure menu”. Conrm your choice

by pressing

.

Every time the boiler is electrically powered, a venting

cycle is run (it lasts 6 min).

Loading...

Loading...