8.2 Switching o and operating phases

During downtimes, deposits must not be produced that can block the cooling system. Check

with the manufacturer of the coolant as to how long it can remain in the cooling system.

8.3 Dealing with faults

If there are deviations from normal operation or if faults occur, initially proceed according to the

following list. In this regard, observe the relevant chapters in the documentation associated with

the components of the complete drive system.

WARNING

Risk to life as a result of non-functioning protective devices

Protective devices that are not functioning can result in death, serious injury or material

damage.

• Do not deactivate protective devices. This also applies to test operation.

• Only work with protective devices that are fully functional.

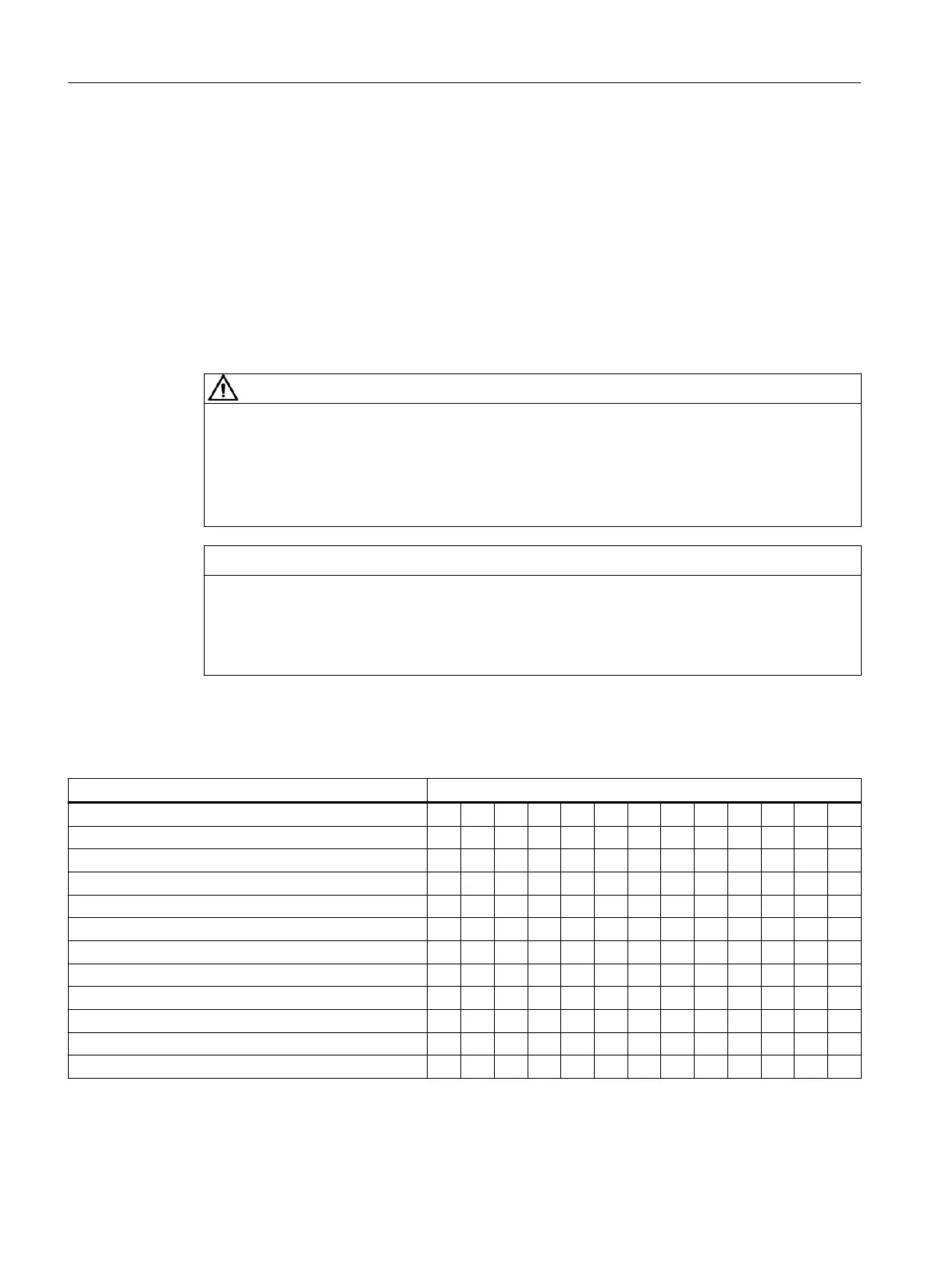

NOTICE

Damage to the machine caused by faults

• Resolve the cause of the fault as specied in the remedial measures section.

• Repair any damage to the machine.

• Replace damaged motors.

Table 8-1 Possible faults

Fault Cause of the fault (see following table)

Motor does not start A B D

Motor starts up slowly A C D E

Humming noise when starting C D E

Humming noise during operation A C D E

High temperature rise during no-load operation D F G

High temperature rise when under load A C F G

Overheating of individual winding sections E

Uneven running H J

Grinding sound, running noise K

Radial vibrations L

Axial vibrations L M

Water is leaking N

Operation

8.3Dealing with faults

1FW6 built-in torque motors

120 Operating Instructions, 09/2022, A5E52220812B AA

Loading...

Loading...