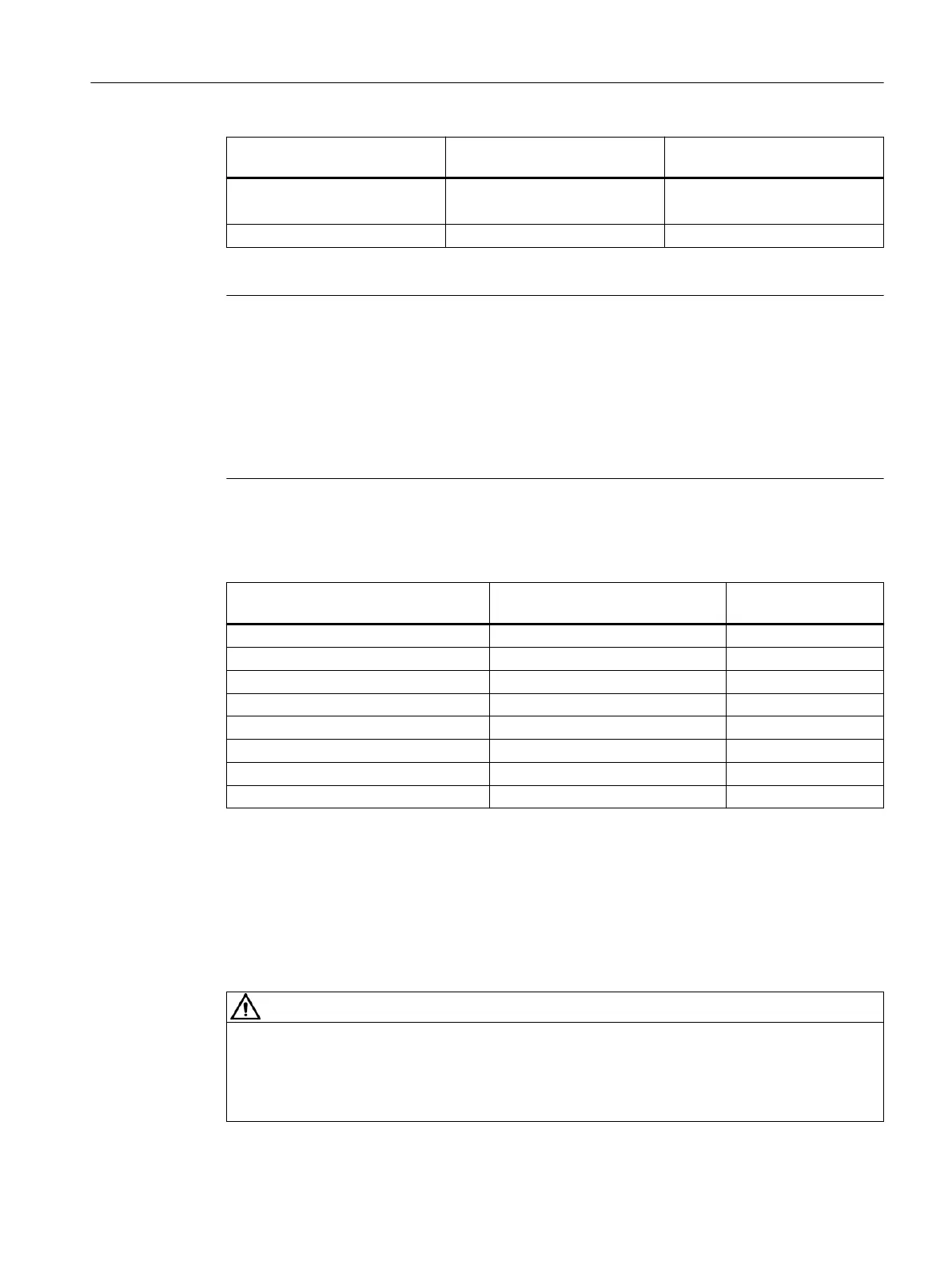

Motor Screw

(strength class)

Tightening torque

M

A

in Nm

1FW6290-xxB07-xxxx to

1FW6290-xxB15-xxxx

M10 (8.8) 43

1FW6290-xxB20-xxxx M10 (10.9) 61.8

Note

Friction value

For the contact surface of the screw head and the screw thread, the friction value µ

tot

= 0.1 is

taken as a basis.

• For smaller friction values, you must reduce the tightening torque and for larger friction

values you must increase the tightening torque.

• Also note the maximum tightening torques of the screws used. These may be lower than the

values specied in the table above.

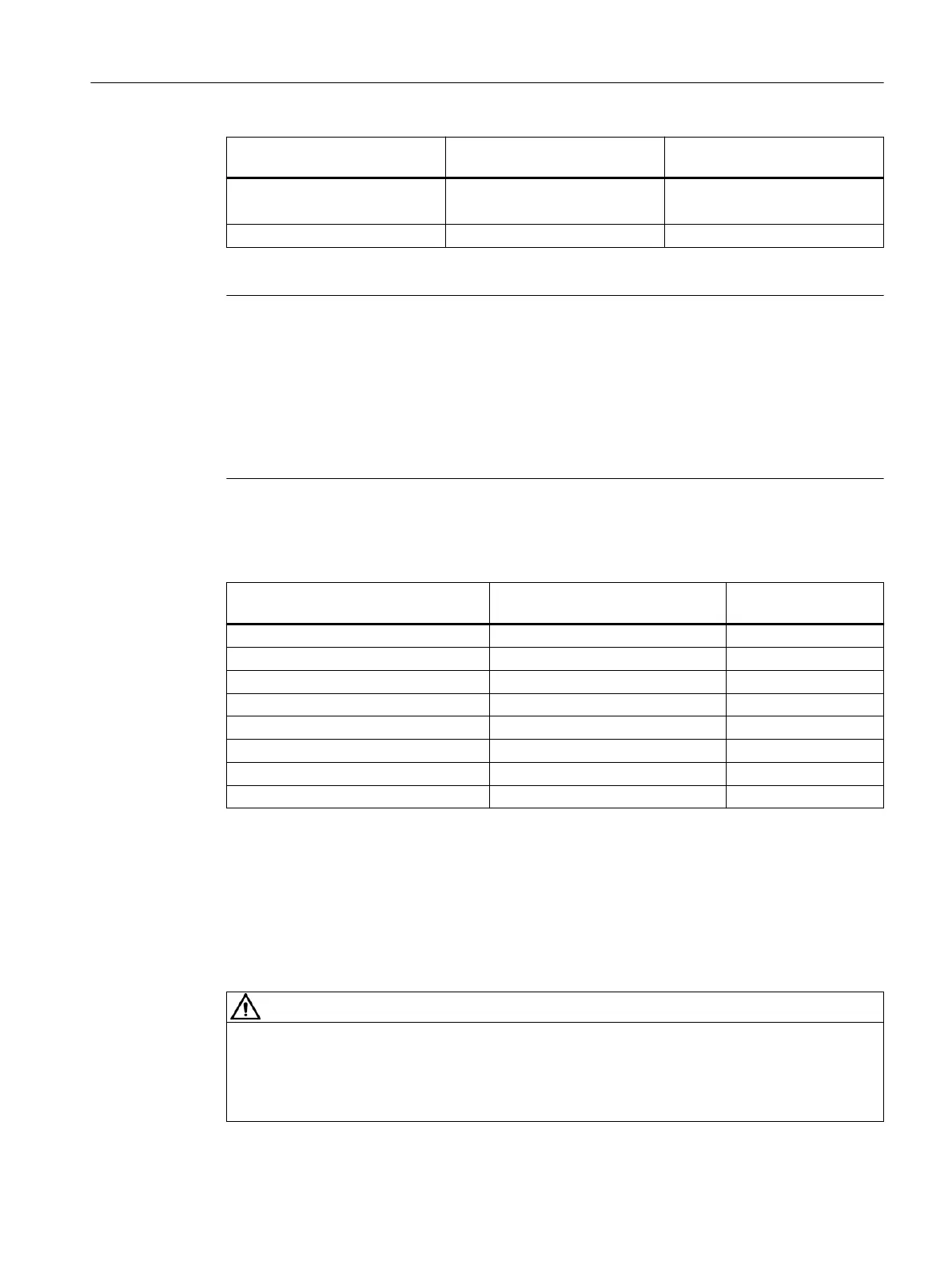

Table 5-5 Maximum permissible screw insertion depths for the stator and rotor

Component max. permissible screw-in depth

in mm

Thread

1FW6050, 1FW6060/stator 8.5 + section without thread *) M6

1FW6050, 1FW6060/rotor 11 M6

1FW6090, 1FW6130/stator and rotor 10 M5

1FW6150 /stator and rotor 12 M6

1FW6160, 1FW6190, 1FW6230/stator 13 M8

1FW6160, 1FW6190, 1FW6230/rotor 12 M8

1FW6290/stator 15 M10

1FW6290/rotor 15 M10

*) On this topic, see installation drawing "Detail Z"

5.7 Procedure for installing the motor

Sequence for installing the motor

WARNING

Risk of injury and material damage

Injury and/or destruction of motor components can occur if you do not observe the specied

sequence when installing the motor.

• Perform work steps in the specied sequence during installation.

Installation

5.7Procedure for installing the motor

1FW6 built-in torque motors

Operating Instructions, 09/2022, A5E52220812B AA 77

Loading...

Loading...