3.1.8 Vibration response

The vibration response of build-in motors in operation essentially depends on the machine

design and the application itself.

As a result of an unfavorable machine design, conguration or system settings, resonance

points can be excited, so that vibration severity levelA according to EN6003414 is not

reached.

Excessive vibration caused by resonance eects can frequently be avoided by making suitable

settings. Contact Application & Mechatronic Support Direct Motors if you require help in

applying remedial measures. You can nd contact data in the Introduction under "Technical

Support".

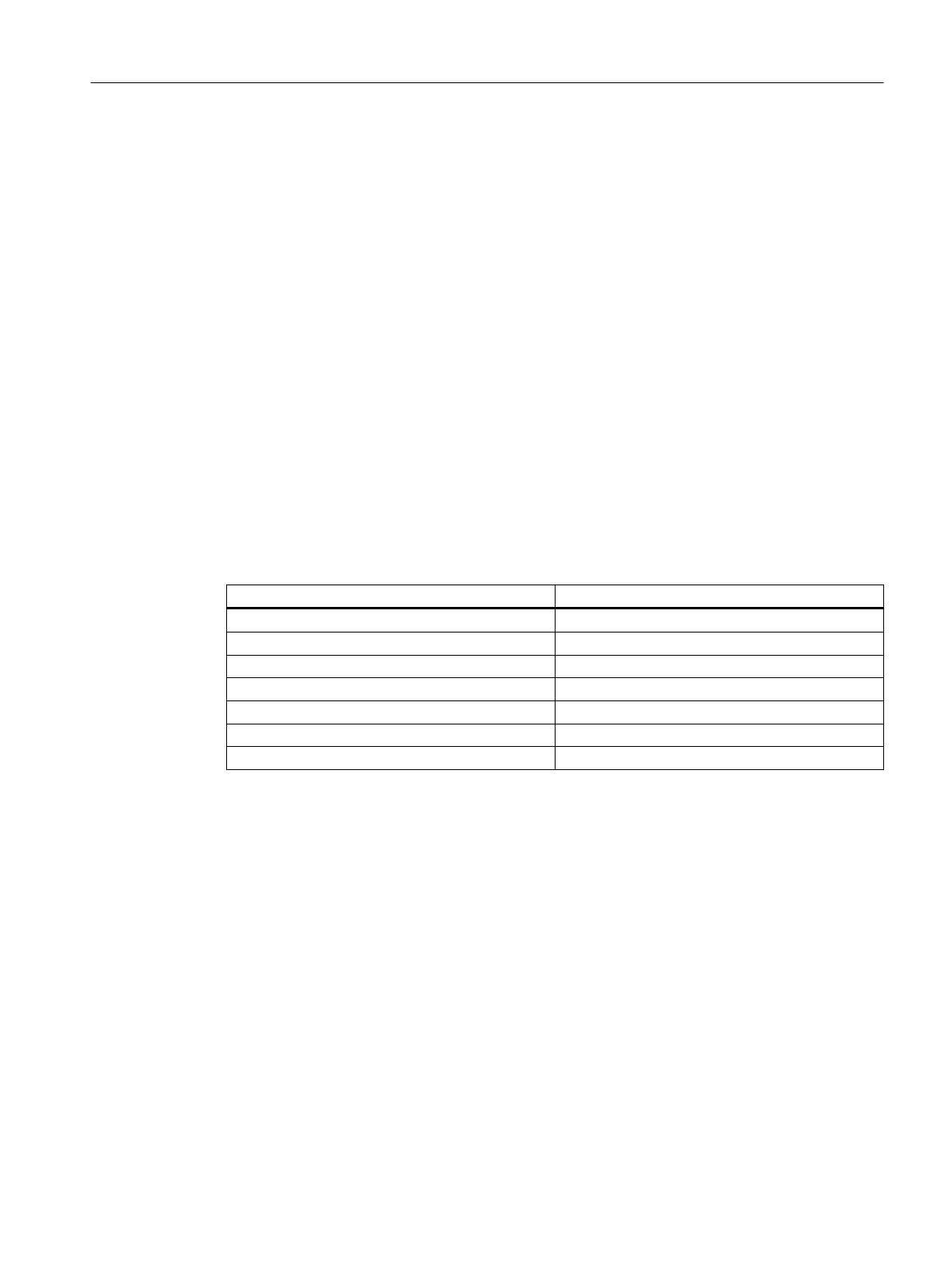

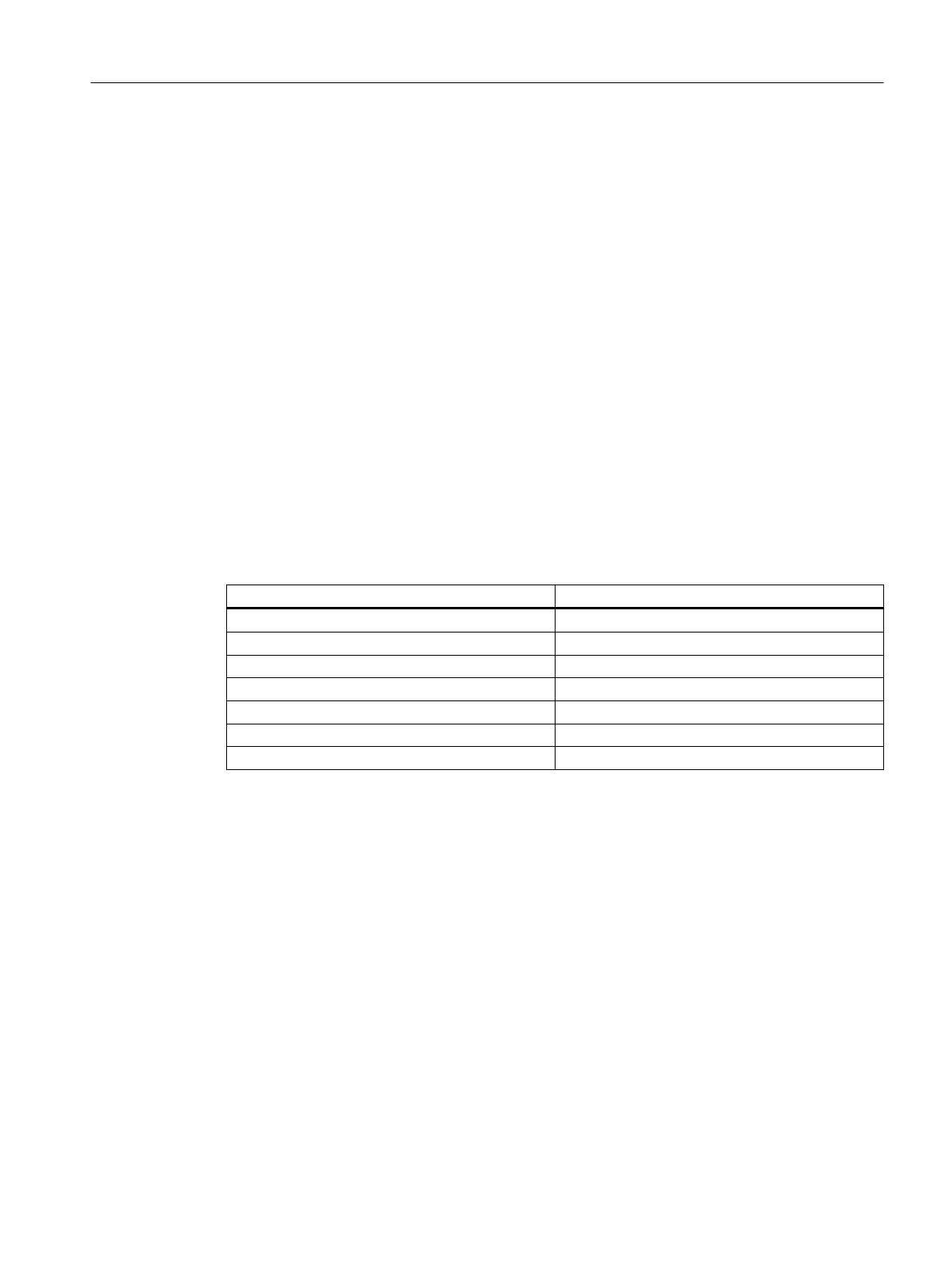

3.2 Derating factors

For installation altitudes more than 2000m above sea level, reduce the voltage stress of the

motors according to the "Factors to reduce the maximum DC link voltage" table (reciprocal

values from EN 60664‑1 Table A.2).

Table 3-3 Factors to reduce the maximum DC link voltage

Installation altitude above sea level in m up to Factor

2000 1

3000 0.877

4000 0.775

5000 0.656

6000 0.588

7000 0.513

8000 0.444

Reducing the DC link voltage reduces the converter output voltage. The operating range in

the M‑n diagram is also reduced.

You can nd the M‑n diagrams in the associated data sheet.

Operation in a vacuum is not permissible due to the low voltage strength and the poor

cooling.

3.3 Rating plate data

Technical data of the stator is provided on the rating plate (name plate). A second rating plate

is provided loose for the stator.

If, at a certain point in time, the stator and rotor are separated, then you must ensure that

the stator and rotor can be assigned to one another at a later point in time.

Description

3.3Rating plate data

1FW6 built-in torque motors

Operating Instructions, 09/2022, A5E52220812B AA 37

Loading...

Loading...