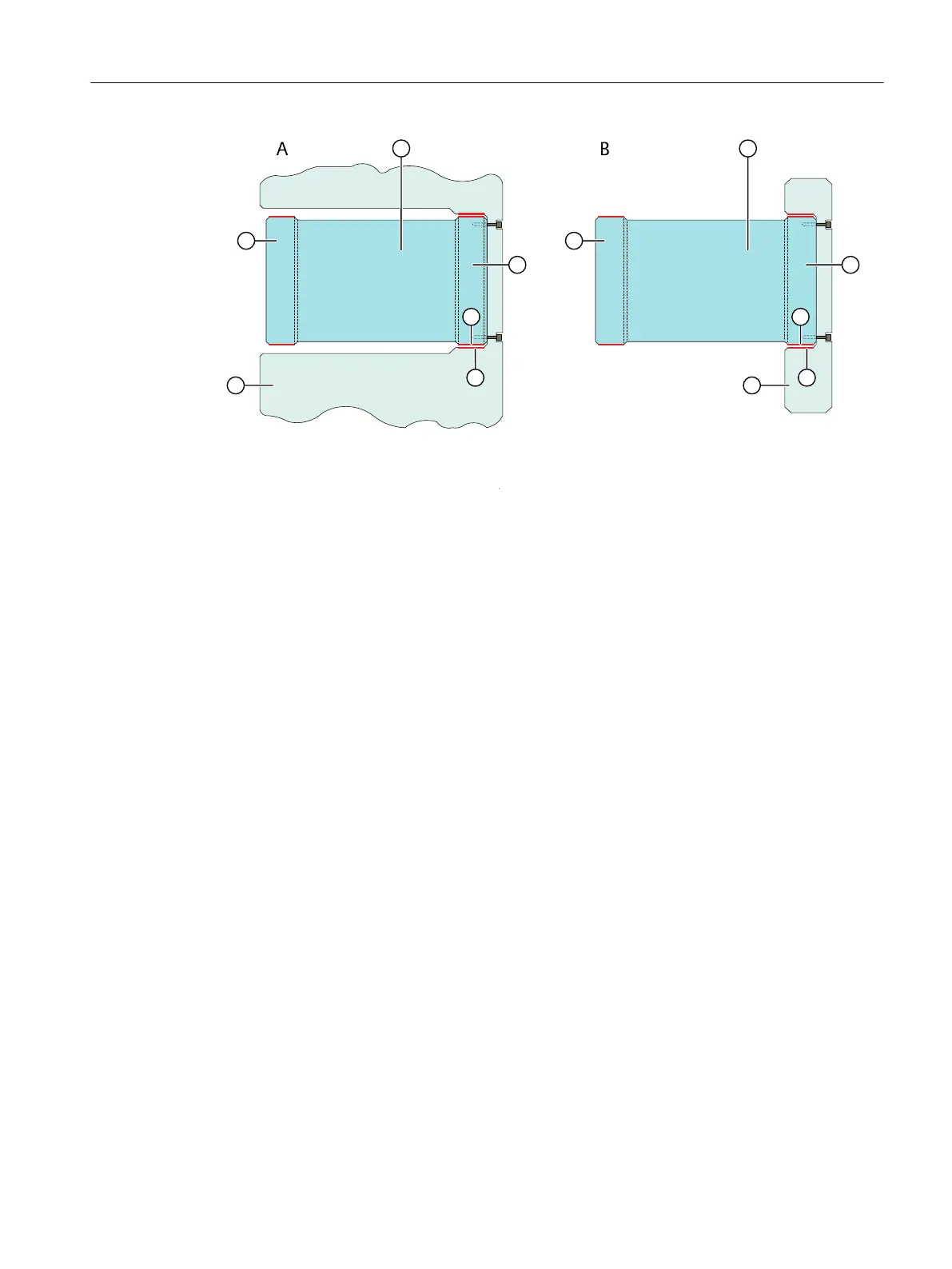

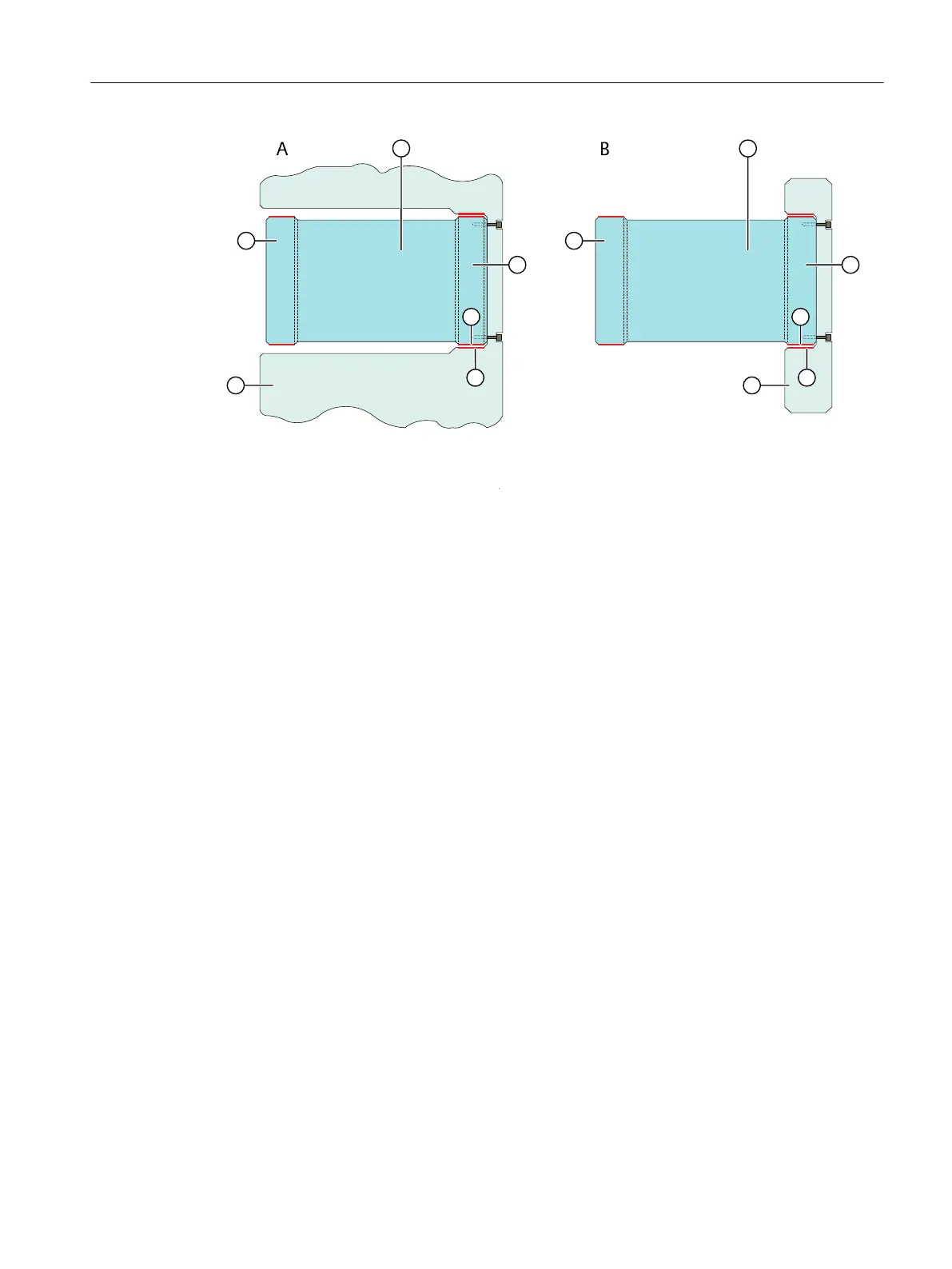

A Installation with enclosure

B Installation without enclosure

① Free ange

② 1FW6 with integrated cooling

③ Mounting ange

④ Fit on the stator side: f8

⑤ Fit on the machine side: H8

⑥ Machine

Figure5-3 Installation types, 1FW6 stator with integrated cooling (schematic)

5.6 Specications for mounting torque motors

Mounting system

Consider the following when mounting the torque motor on the axis structure:

• Only use new (unused) xing screws.

• The mounting surfaces must be free of oil and grease.

• Carefully observe the maximum permissible screw-in depth of the xing screws in the stator

and rotor according to the relevant installation drawing or the following table

• The minimum insertion depth for the xing screws in the stator:

1.0 x d + section without threads (valid for 1FW6050 and 1FW6060)

1.3 x d (valid for 1FW6090 to 1FW6130)

1.0 x d (valid for 1FW6150 and higher)

• Minimum insertion depth of the xing screws in the rotor ange (in steel):

1.1 x d (valid for 1FW6050 and 1FW6060)

1.0 x d (valid for 1FW6090 to 1FW6290)

Installation

5.6Specications for mounting torque motors

1FW6 built-in torque motors

Operating Instructions, 09/2022, A5E52220812B AA 75

Loading...

Loading...