• To free jammed parts of the body (e.g. hands, ngers, feet), pull apart components that are

clamped together.

– Do this using the non-magnetic hammer to drive the non-magnetic wedges into the

separating rift.

– Release the jammed body parts.

• If necessary, call the emergency medical service or an emergency physician.

Material damage caused by strong magnetic elds

NOTICE

Data loss caused by strong magnetic elds

If you are close to the rotor (<100mm) any magnetic or electronic data medium as well as

electronic devices that you are carrying can be destroyed. For example, credit cards, USB sticks,

oppy disks and watches are at risk.

• Do not carry any magnetic/electronic data media and no electronic devices when you are

close to a rotor!

3.1.3 Technical features

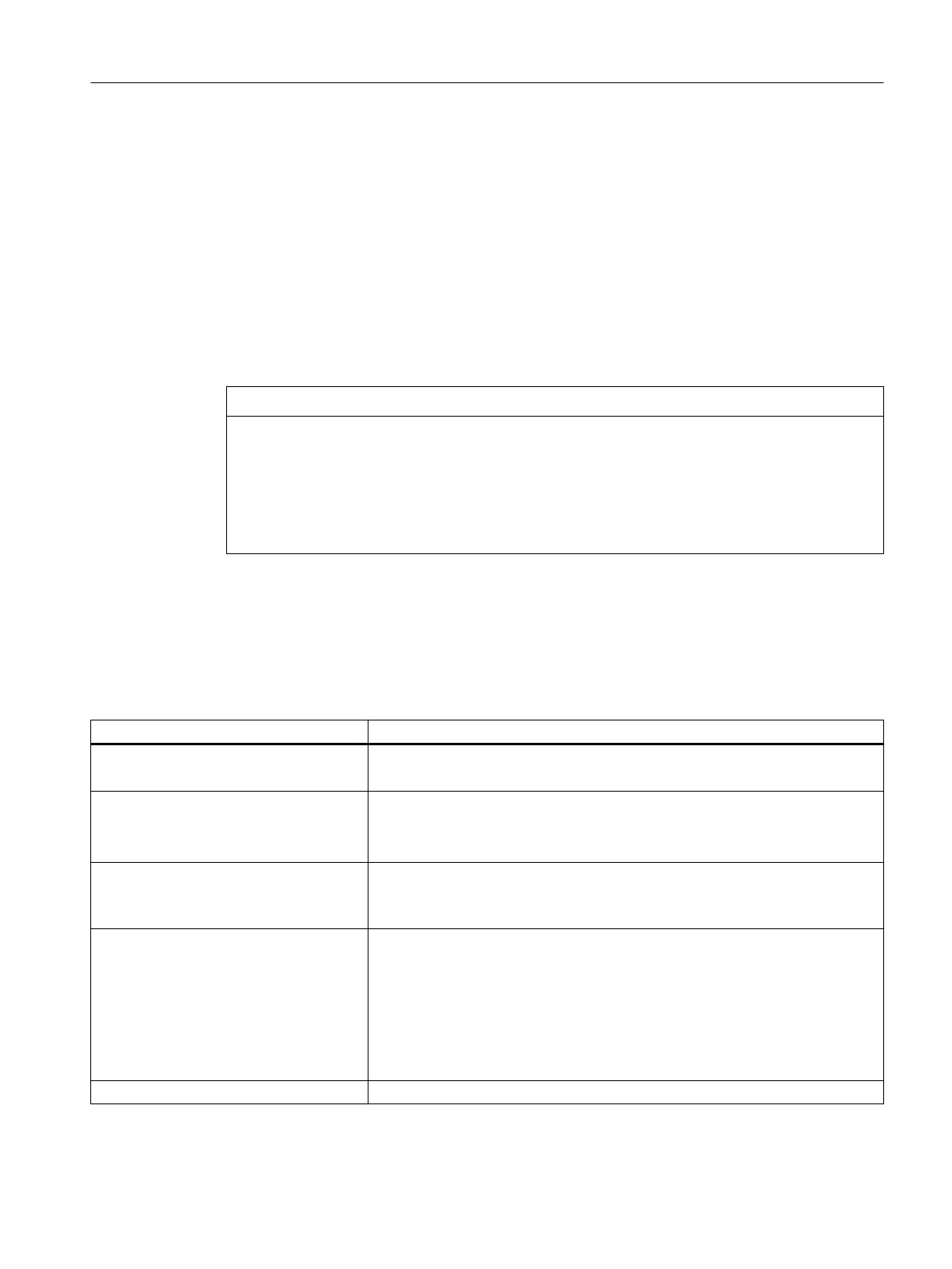

Table 3-1 Standard version of the 1FW6 built-in torque motor

Technical feature Version

Type of motor Synchronous motor with permanent magnet rotor

• High number of poles, rotor pole number from 22 up to 98

Type of construction Individual components

• Stator

• Rotor

Degree of protection according to

DINEN60034-5

Motor: IP23

• The nal degree of protection (minimum degree of protection: IP54) of the

installed motor must be realized by the machine manufacturer

Cooling method Water cooling

• Jacket cooling:

sizes 1FW6090, 1FW6130, 1FW6150

• Integrated cooling (1 cooling circuit):

frame sizes 1FW6050 and 1FW6060

• Integrated cooling (2 cooling circuits):

frame sizes 1FW6160, 1FW6190, 1FW6230, 1FW6290

Pressure in the cooling circuit Max. 10 bar (static)

Description

3.1Technical features and ambient conditions

1FW6 built-in torque motors

Operating Instructions, 09/2022, A5E52220812B AA 31

Loading...

Loading...