7 - 25

7 Transmission Repair

7B Eaton 750 / 751

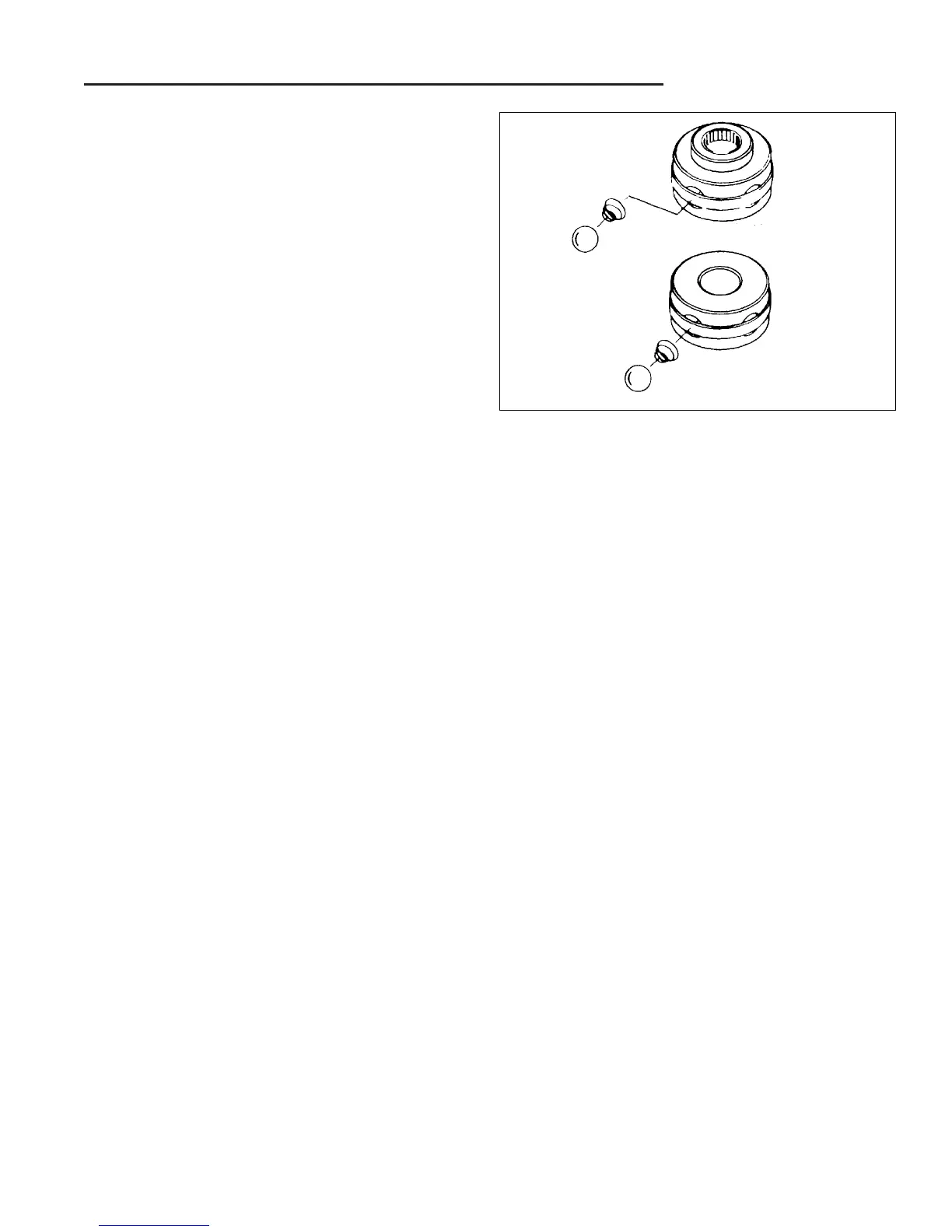

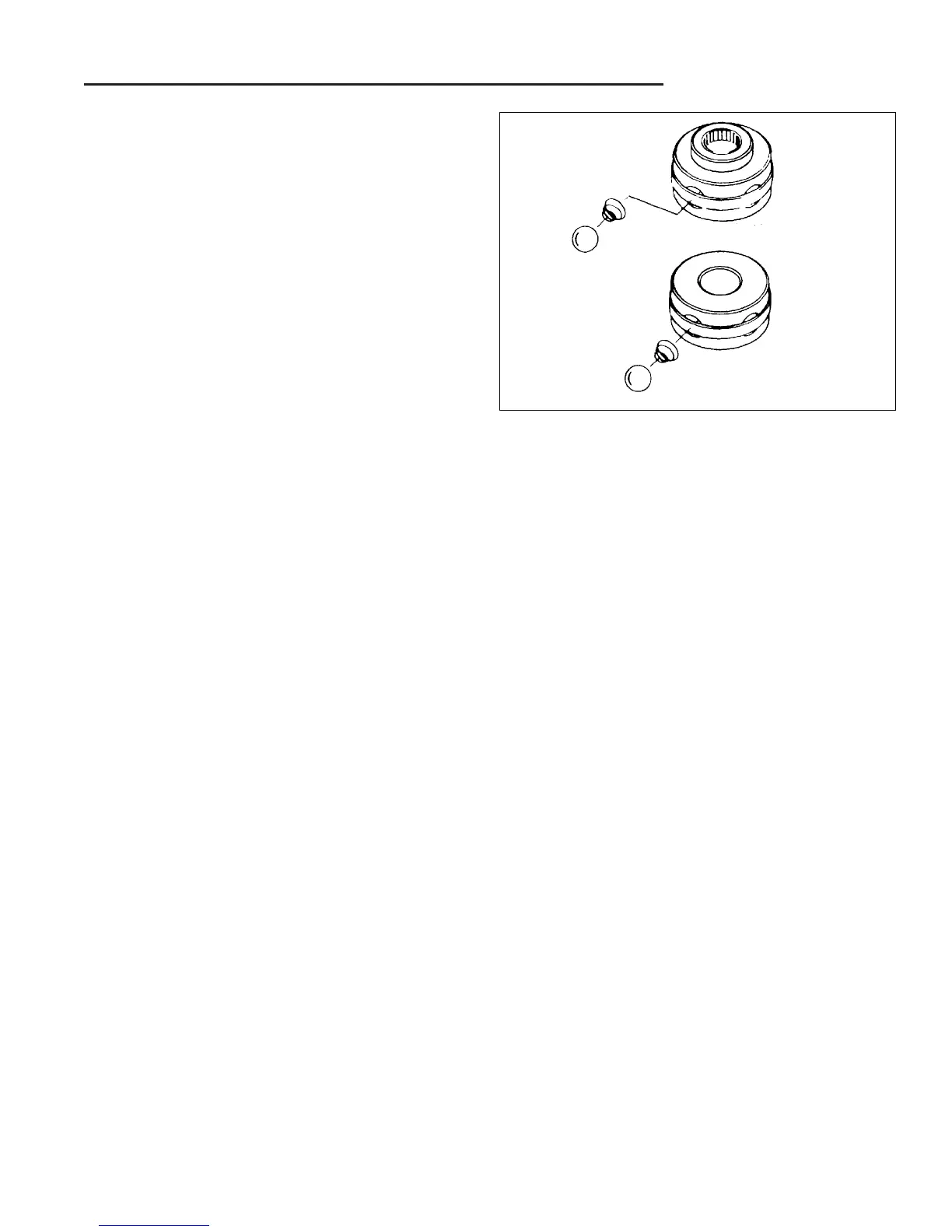

Figure B–58. Inspect rotor assemblies

Rotor Disassembly and Inspection

1. Inspect the rotor assemblies in the following manner.

Remove the piston balls from the rotor, one at a time,

working clockwise from the letter stamped in the rotor

face. Place the piston balls in a prepared container.

NOTE: The balls must be replaced in the same bores

from which they were removed because they are all

select fit. Use a container such as an egg carton or ice

cube tray to hold the balls.

2. Check for broken or collapsed springs in the motor

rotor assembly.

Inspect the piston balls. They must be smooth and

completely free of any irregularities.

Inspect the rotor bores, rotor bushing and pintle jour-

nals for irregularities or excessive clearance. The ball

piston to rotor bore clearance is select fit electronical-

ly from .0002 to .0006”. When irregularities are noted,

replace the complete rotor assembly. Individual ball

and spring are not serviceable.

Install the piston balls in their matching bores. Hold

them in place with a rubber band or separate race.

General Reassembly Notes

Before reassembling the transaxle, clean all parts and

assemblies with clean solvent and blow dry with com-

pressed air. Inspect and replace all scratched or dam-

aged parts. Replace all gaskets, seals and seal rings.

Lubricate all seals and seal rings with petroleum jelly

(Vaseline) for retention during assembly. Freely lubricate

all bearings and finished part surfaces with clean

hydraulic fluid to provide lubrication at start-up.

To ensure correct installation, the axle housings are

marked with the letters A and B. Each side of the hous-

ing assembly is also marked with an A or B. Make sure

the axle housings are correctly assembled with the corre-

sponding letters on the housing assembly.

Loading...

Loading...