6 - 21

6 General Repair

6B Hand Controls Repair

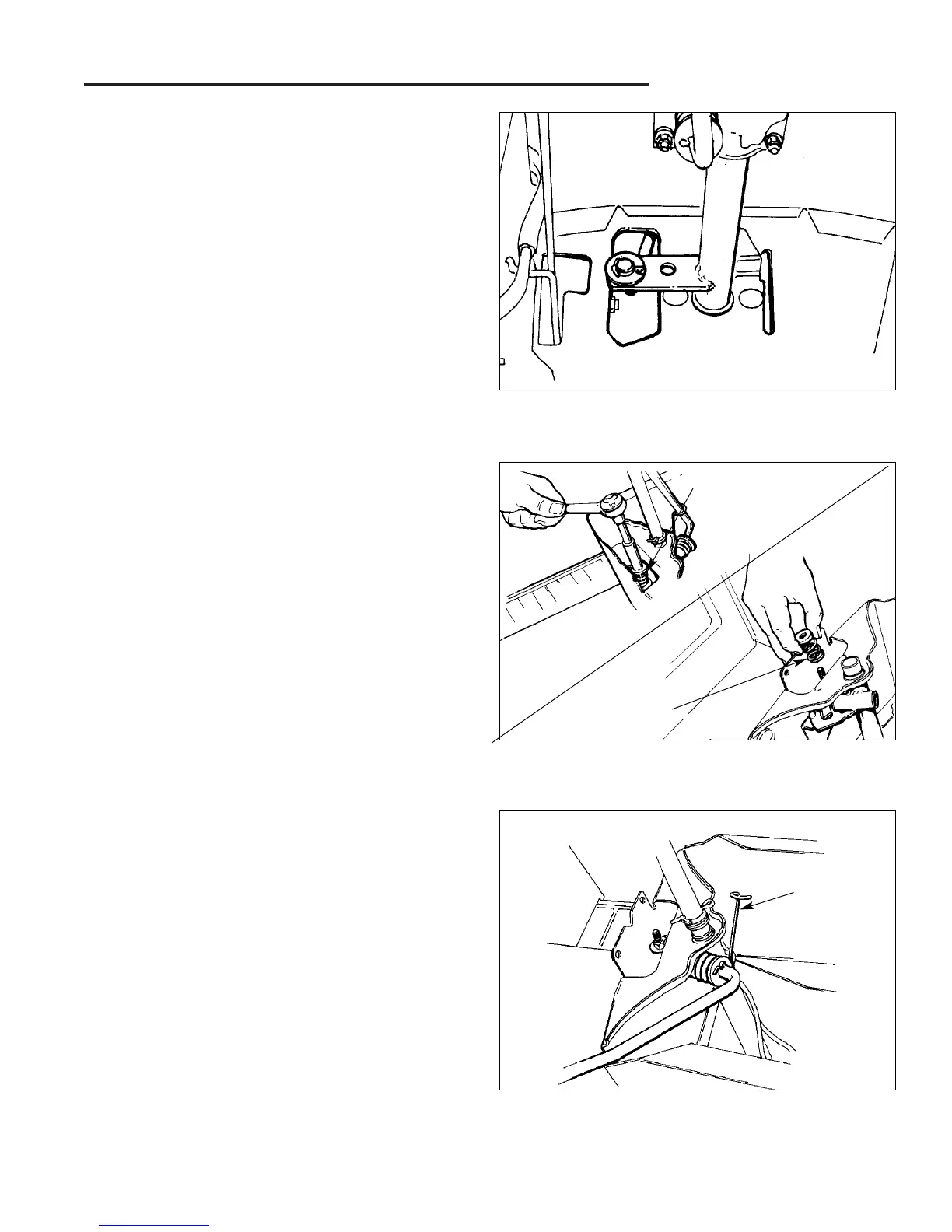

Figure B–8. Broadmoor Hydro Shift/Lift Lever

Access Area

Shift Lever Assembly Service

Shift lever assembly service requires that the dashboard

be removed. Refer to the Hood, Dash, and Grill Repair

section for dashboard removal instructions.

After the dash assembly is fully separated from the unit,

set it aside carefully to prevent damage to electrical com-

ponents.

The lift lever, and shift lever assemblies are now fully ac-

cessible, as is the steering column shaft, and front trans-

mission shift rod connection to the shift lever assembly.

(Figure B–8).

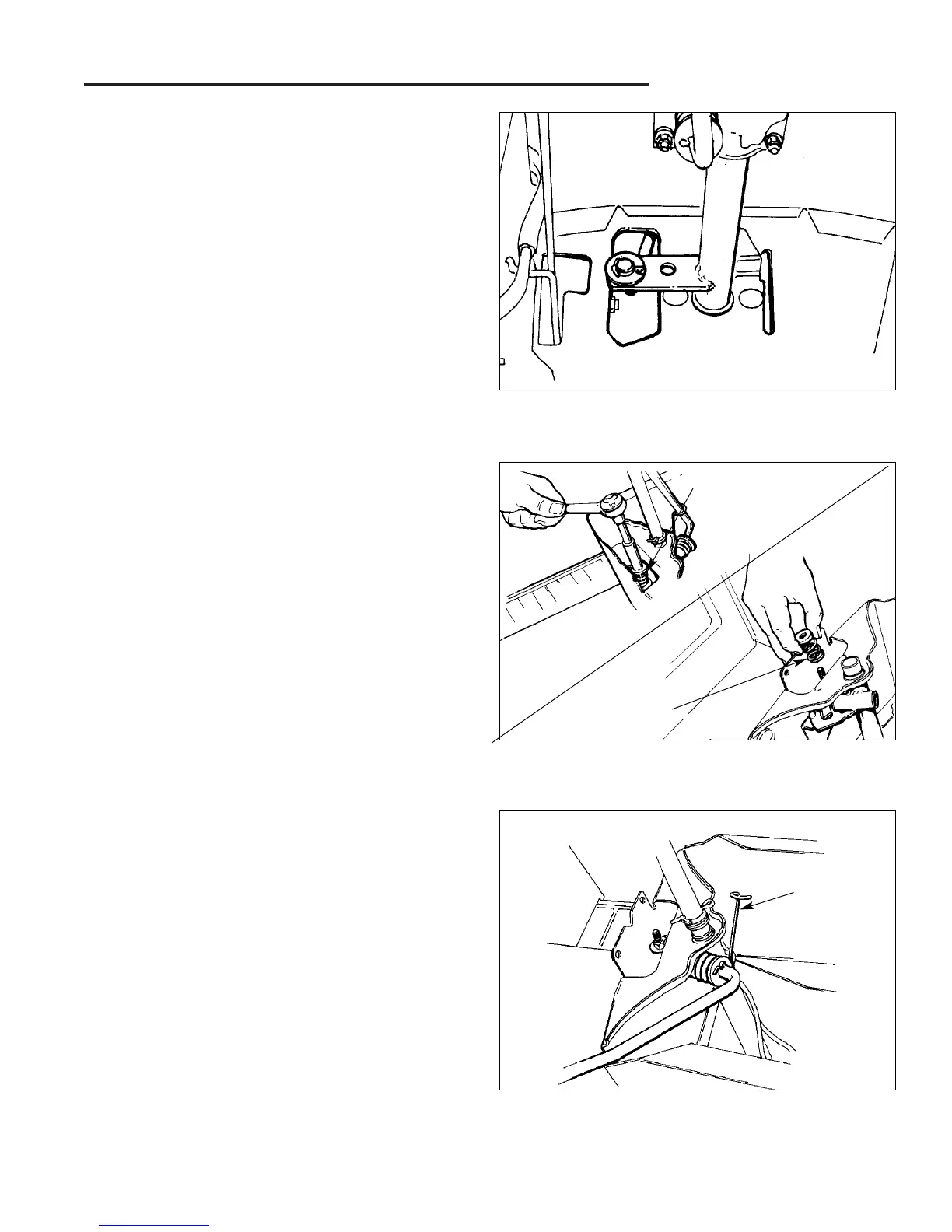

Figure B–9. Adjust Spring Tension

Shift Lever Spring Adjustment

Tension on the shift lever may be increased or de-

creased by adjusting the tension on the shift lever com-

pression spring (K, Figure B–3 Later Model Shift Lever

Assembly). The correct tension for proper shift lever op-

eration should be obtained when the adjustment locknut

(I, Figure B–3) is torqued to 75 - 100 in./lbs.

1. Using a 1/2 deep socket with a 4" - 6" extension bar,

remove the tension adjustment locknut and compres-

sion spring (Figure B–9). Inspect spring and sur-

rounding parts for signs of wear or breakage, and re-

place as needed.

2. Reassemble parts in position as shown in Figure

4B–4, and torque to 75 - 100 in./lbs.

Figure B–10. Disengage Torsion Spring

Shift Lever Replacement

1. Release tension on the shift lever by disengaging the

torsion spring’s (E, Figure B–3) hooked end from the

shift lever shaft. (Figure B–10)

Torsion

Spring

Tension Spring

Tension Spring

Loading...

Loading...