TUP500 Series Product Specifications 3-16

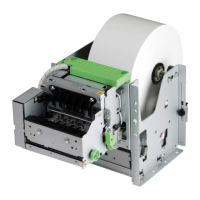

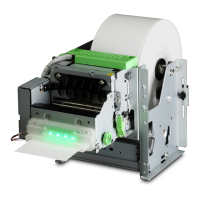

3.4. Thermal Mechanism Module

(1) Refer to the TMP500 Series Product Specifications Manual for details on the thermal mechanism.

3.4.1. Thermal Head

(1) Thermal Element Configuration: 2 elements/dot

(2) Number of thermal elements: 640 Dots

(3) Thermal element scanning density: 0.125 mm/Dots (8 Dots/mm)

(4) Average resistance value: 800 ±3% (initial value)

(5) Drive power voltage: Head drive/Vh = 24 VDC ±10%,

Driver IC/Vdd = 5 VDC ±5%

3.4.2. • Auto-cutter

(1) Cutter type: Sliding Sheart Method (Separated Type)

(2) Paper Cut States: Full Cut

(3) Cutting Duty: 3 seconds/cut

(4) Cutting Position: Distance from Printing Position to Cutting Position: 11 ±0.5 mm

(5) Paper Thickness: 65 µm to 150 µm

(6) Error Detection: Home position detected by mechanical sensor.

Notes:

1. When not using the cutter within the cut duty range described above, the life of the auto-

cutter will be notably shortened.

2. Cutter life specifications vary according to the thickness of the paper that is used.

3. When printing after cutting the paper, it is recommended that you feed paper at least 1 mm

(8-dot line).

4. If the cutter is not at the cutting position after the error, either turn the power on again af-

ter removing the cause of the error, or turn the emergency know to return the cutter blade

to its home position following the arrow marked on the housing from the notch portion in

the cutter unit housing.

The emergency knob should be rotated using a tweezers, screwdriver or ball-point pen to

prevent accidents.

5. For models without the presenter installed, remove the paper is completely cut.

Removing the paper while it is being cut will cause pieces of paper to be generated, or it

can cause paper jams.

6. If the cutter locks up because of the encroachment of the paper, absolutely do not force

open the frame for fastening the mechanism (mechanism and presenter). The cutter can

be damaged if the cover is forced open.

3.4.3. Paper Feed Motor

(1) Format: 4 Phase PM Type Bipolar Stepping Motor

(2) Drive Voltage: 24 VDC ± 10%

3.4.4. Sensors

(1) Head Temperature Detection: Detects the temperature of the thermal head with

a thermistor.

(2) Paper Out Detection: Reflective type photo-sensor detects the trailing end of

the paper

(3) Cover Open Detection: Micro-switch Detects that the cover (between Head and

Platen) is closed.

(4) Cutter Home Position Detection: Micro-switch

Notes:

1. The paper out detector duals as the black mark detector. In such cases, some restrictions

exist for black mark pitch detection.

Loading...

Loading...