Loading...

Loading...

Do you have a question about the Star Micronics TUP500 series and is the answer not in the manual?

| Brand | Star Micronics |

|---|---|

| Model | TUP500 series |

| Category | Printer |

| Language | English |

Explains how to interpret the TUP500 model name structure.

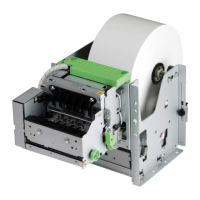

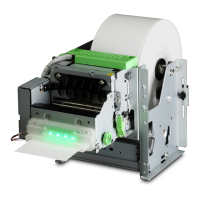

Describes the modular composition of the TUP500 printer.

Lists selectable options for printer modules.

Details printing method, dot configuration, density, and region.

Details character and barcode specifications for STAR Line Mode.

Covers paper width, thickness, and external diameter specifications.

Details thermal head configuration, density, and voltage.

Details presenter conveyance roller feed method and speed.

Details roll paper support, width adjustment, and paper tube specs.

Covers mechanical, thermal head, and auto-cutter reliability.

Details external dimensions of printer units.

Explains the function of the power and feed/cancel switches.

Details operating and storage temperature/humidity ranges.

Lists emission standards and limit values.

Specifies vibration test conditions.

Lists country-specific compatible standards.

Explains layout considerations for the optional paper holder.

Instructions for mounting the printer and optional units.

Step-by-step assembly for horizontal layout.

Instructions for fastening friction spring.

Method for adjusting sensor position for paper width.

Step-by-step guide for loading roll paper.

Instructions for periodic cleaning of thermal mechanism and presenter.

Important safety and handling precautions for the printer.

General safety precautions for printer operation and maintenance.

Overview of interface, power, dimensions, and board components.

Visual representation of the printer's circuit connections.

Details connectors and their signal assignments on the control PCB.

Details DIP switch settings for various interfaces.

Specifies memory switch settings for destination and character modes.

Specifies memory switch settings for top margin, fonts, and international characters.

Specifies memory switch settings for print speed and density.

Specifies memory switch settings for code pages and character positions.

Specifies memory switch settings for print mode and region.

Specifies memory switch settings for presenter auto-recovery and snout control.

Specifies memory switch settings for auto-loading and presenter paper position.

Specifies memory switch settings for ASB functions.

Specifies memory switch settings for loaded format on power-on.

Specifies memory switch settings for NE sensor input.

Overview of printer operations via switches and LEDs.

Details the meaning and behavior of system LEDs.

Describes auto-recovery errors and their cancellation.

Procedure to adjust PE/Black Mark sensor sensitivity.

Refers to separate document for STAR Line Mode command specs.