1D-57 Power Unit Mechanical:

4) From number stamped on conrod and its cap and

alphabets stamped on crank web No.1, Determine

new standard bearing to be installed into conrod big

end, by referring to the table.

For example, if number stamped on conrod and its

cap is “1” and alphabet stamped on crank web No.1

is “B”, install the bearing painted “Black” as a new

standard bearing to conrod big end.

Matching chart of conrod bearing

NOTE

Measure conrod big end oil clearance again

after installing new bearing selected.

Refer to “Conrod Big End Oil Clearance”

under “Crank Pin and Conrod Bearing

Inspection” (Page 1D-54)

Crankshaft Inspection

Z9J0111406024

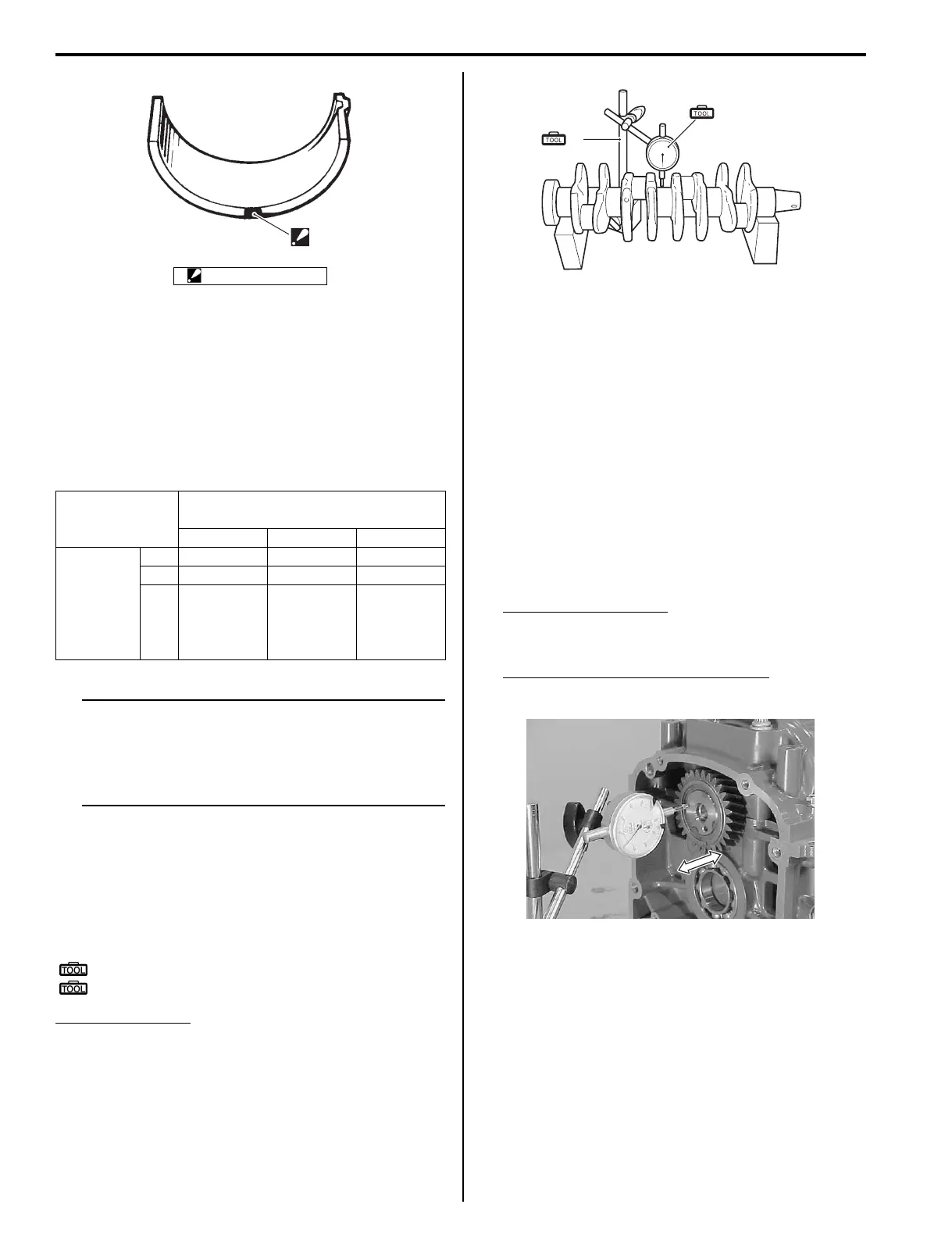

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

If measurement exceeds service limit, replace

crankshaft.

Special tool

(A): 09900–20606 (Dial gauge)

(B): 09900–20701 (Magnetic stand)

Crankshaft runout

Service limit: 0.04 mm (0.0016 in.)

Crankshaft Thrust Play

1) Measure thrust play with crankshaft, thrust bearing,

journal bearing and crankcase / cylinder block

assembled in a normal manner.

Tighten crankcase bolts to specified torque.

Tightening torque

Crankcase bolt (Inside 10 mm): 52 N·m (5.2 kgf-

m, 37.5 lbf-ft)

Crankcase bolt (Outside 8 mm): 25 N·m (2.5 kgf-

m, 18.1 lbf-ft)

2) Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If measurement exceeds service limit, replace

crankshaft thrust bearing.

Crankshaft thrust play

Standard: 0.11 – 0.31 mm (0.0043 – 0.0122 in.)

Service limit: 0.35 mm (0.0138 in.)

Crankshaft thrust bearing thickness

Standard: 2.47 – 2.52 mm (0.0972 – 0.0992 in.)

“F”: Color mark

Number stamped on conrod and its

cap (Big end diameter)

123

Alphabet

stamped

on crank

web No.1

(Crank pin

diameter)

A Green Black Nothing

B Black Nothing Yellow

C Nothing Yellow Blue

“F”

I9J011140268-01

(A)

(B)

I9J011140257-02

I9J011140258-02

Loading...

Loading...