Engine Electrical Devices: 1C-1

Power Head

Engine Electrical Devices

Precautions

Precaution for Engine Electrical Device

Z9J0111300001

Refer to “General Precautions” in Section 00 (Page 00-1) and “Precautions on Engine Diagnosis” in Section 1A

(Page 1A-1).

General Description

Sensor and Switch Description

Z9J0111301001

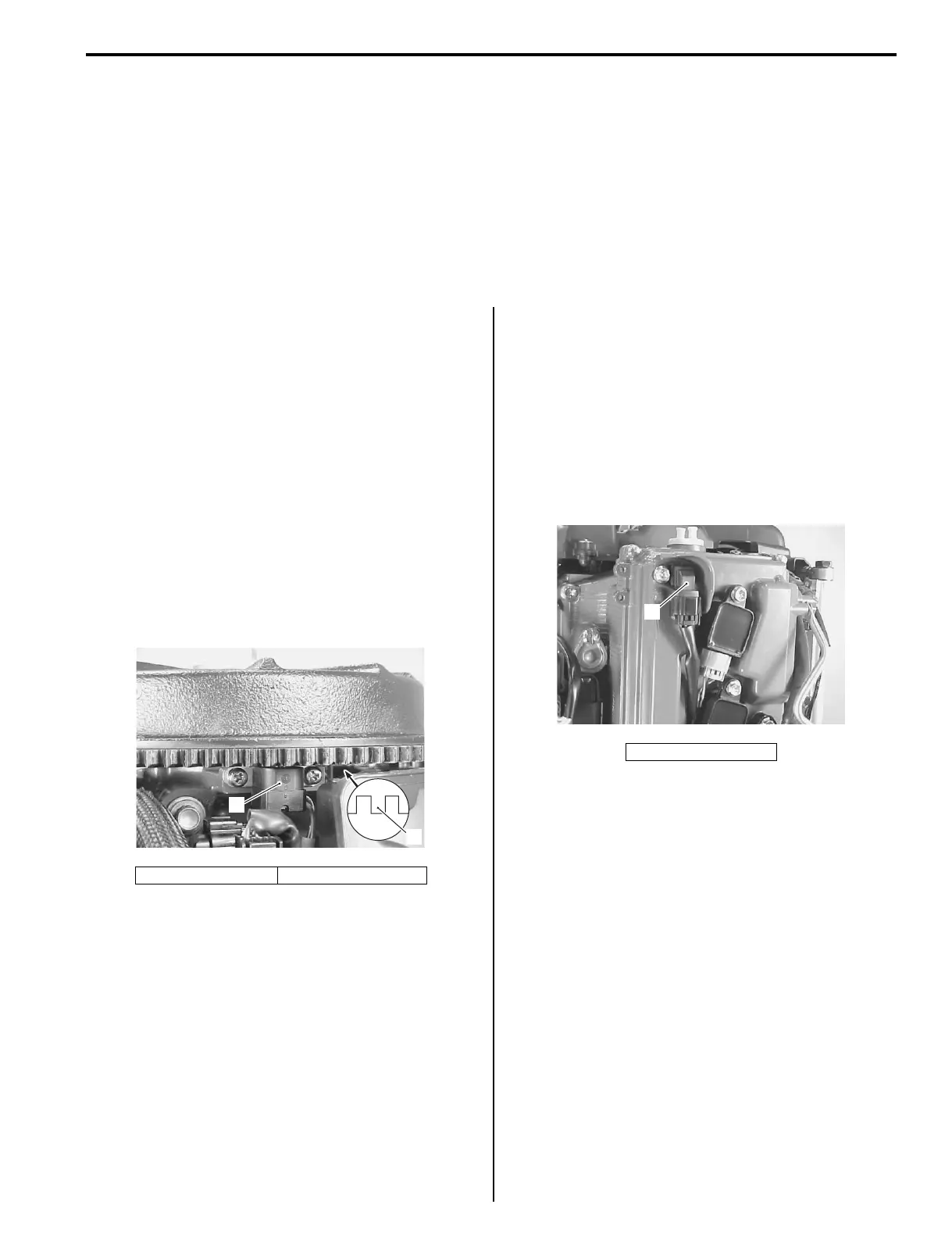

CKP Sensor

• There is one CKP sensor installed below the flywheel

rotor.

When the reluctor bars on the flywheel pass the

sensor, a signal (voltage pulse) is generated and sent

to the ECM. This is the fundamental signal used to

judge engine speed and crankshaft angle.

• There are 32 reluctor bars. They are located 10

degrees apart, except at two positions where they are

30 degrees apart.

During one crankshaft rotation, 32 signals are input to

the ECM.

• Failure symptom:

Without the CKP sensor signal input, the ECM does

not output the ignition and fuel injection signals.

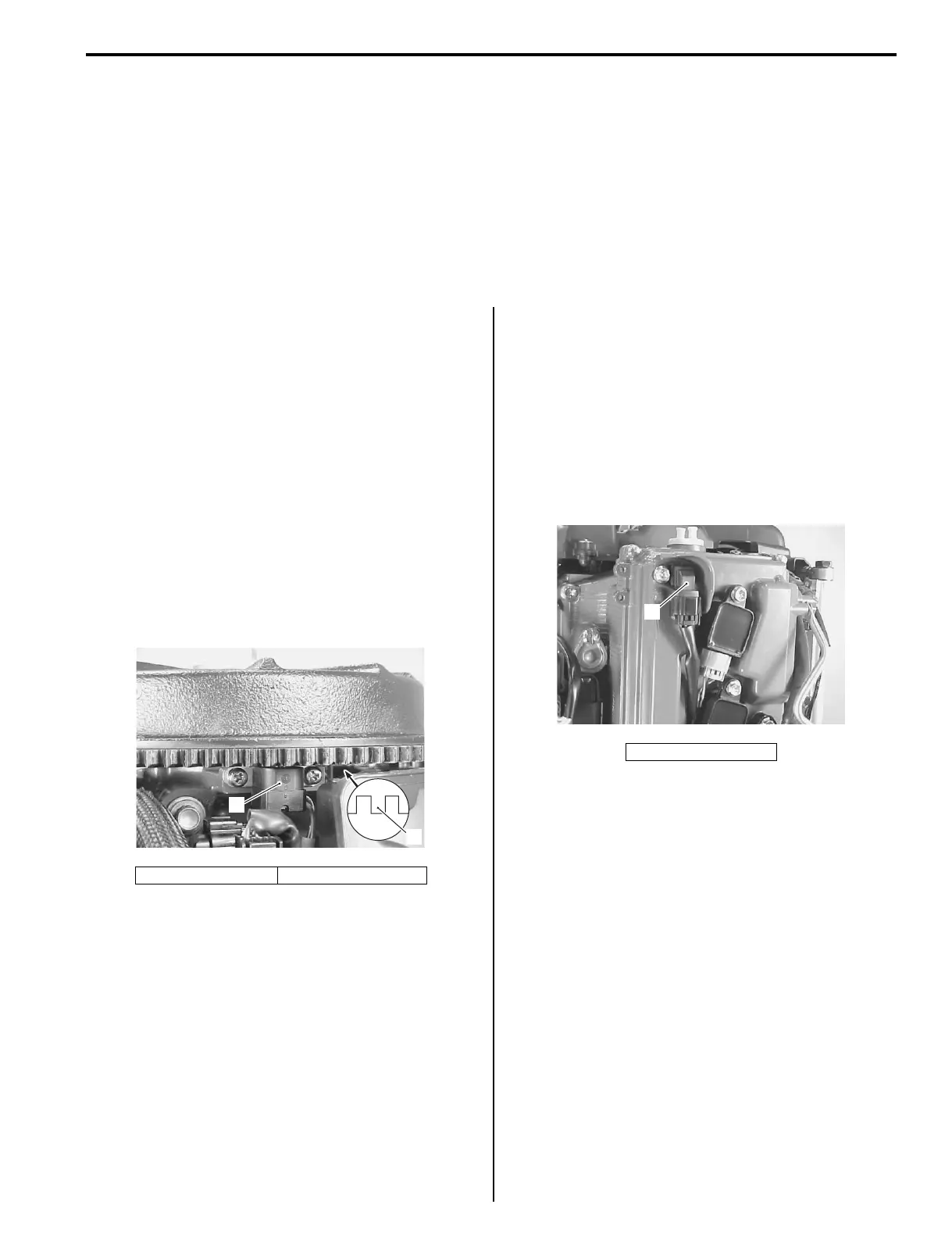

CMP Sensor

• The CMP sensor is mounted on the cylinder head

cover and the trigger vanes are pressed onto the end

of the exhaust camshaft.

This sensor is used to detect piston position.

• Signals received from this sensor are also used by the

ECM to determine sequential fuel injection and

ignition control.

• The 12 V power to the CMP sensor is supplied

through the Ign (Gr) line of the ignition switch.

1. CKP sensor 2. Reluctor bar

1

2

I9J011130026-01

1. CMP sensor

1

I9J011130027-01

Loading...

Loading...