1G-21 Fuel System:

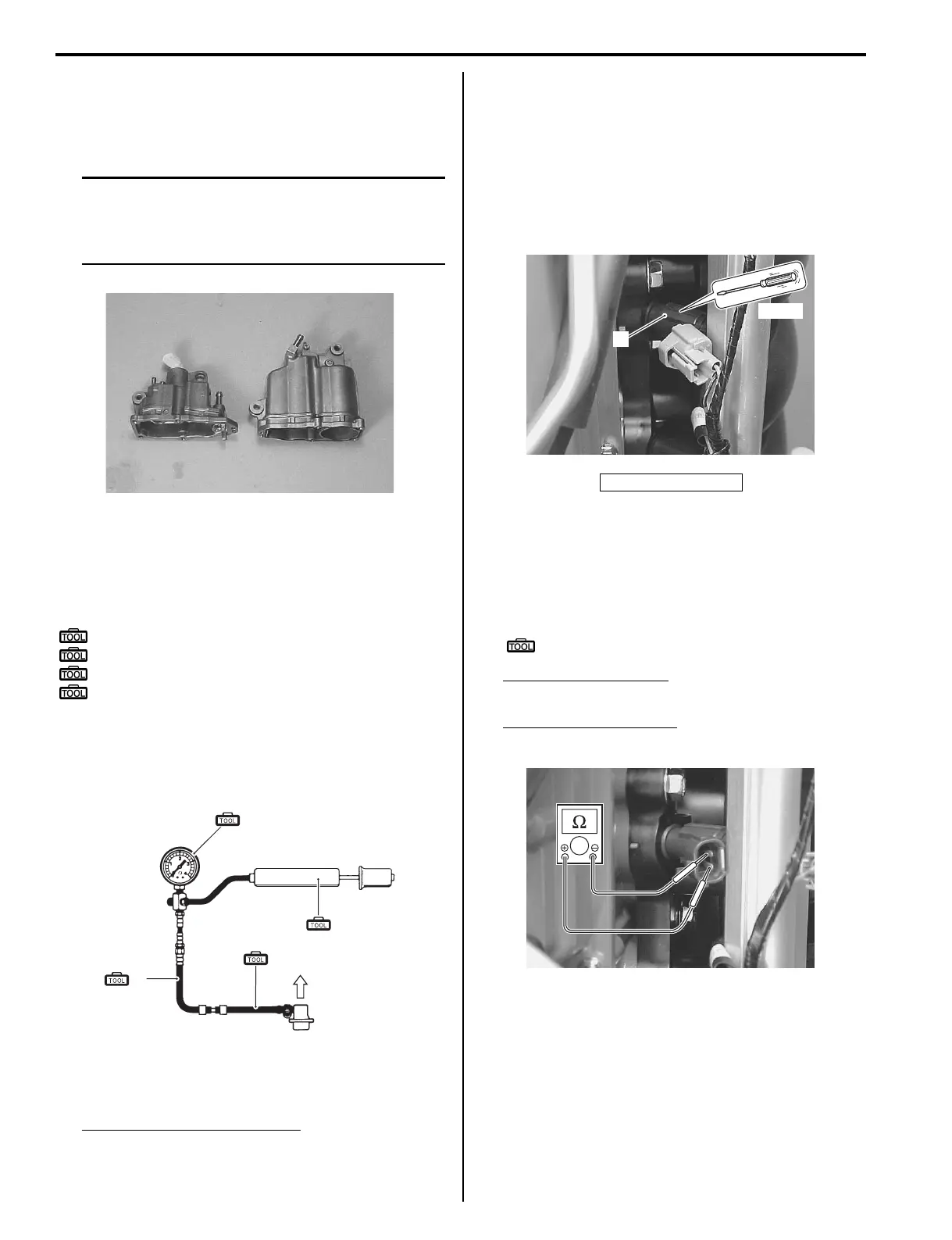

Separator Cover and Case

Inspect the separator cover and case.

Replace if cracked, damaged or other abnormal

conditions.

NOTE

Separator cover and case are a set.

If any repair is required on the cover or case,

replace them as a fuel vapor separator

assembly.

Fuel Pressure Regulator

Inspect the fuel pressure regulator for damage or

corrosion.

Check the fuel pressure regulator operation.

Special tool

(A): 09952–99310 (Hand air pump)

(B): 09940–44121 (Air pressure gauge)

(C): 09940–44130 (Attachment)

(D): 09912–58490 (3-way joint & hose)

1) Connect the special tools to the inlet side of the

regulator as shown in the figure.

2) Pump air into the regulator using pump until air is

released through outlet side.

3) Read the pressure on the gauge when air is

released.

If out of specification, replace regulator.

Regulator operating pressure

Standard: 240 – 270 kPa (2.4 – 2.7 kg/cm

2

, 34.1 –

38.4 psi.)

Fuel Injector Inspection with Injector in place

Z9J0111706010

1) Using a sound scope or equivalent, check the

operating sound of the fuel injector when the engine

is running or cranking.

Injector operating sound cycle should vary according

to engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or connector) or injector.

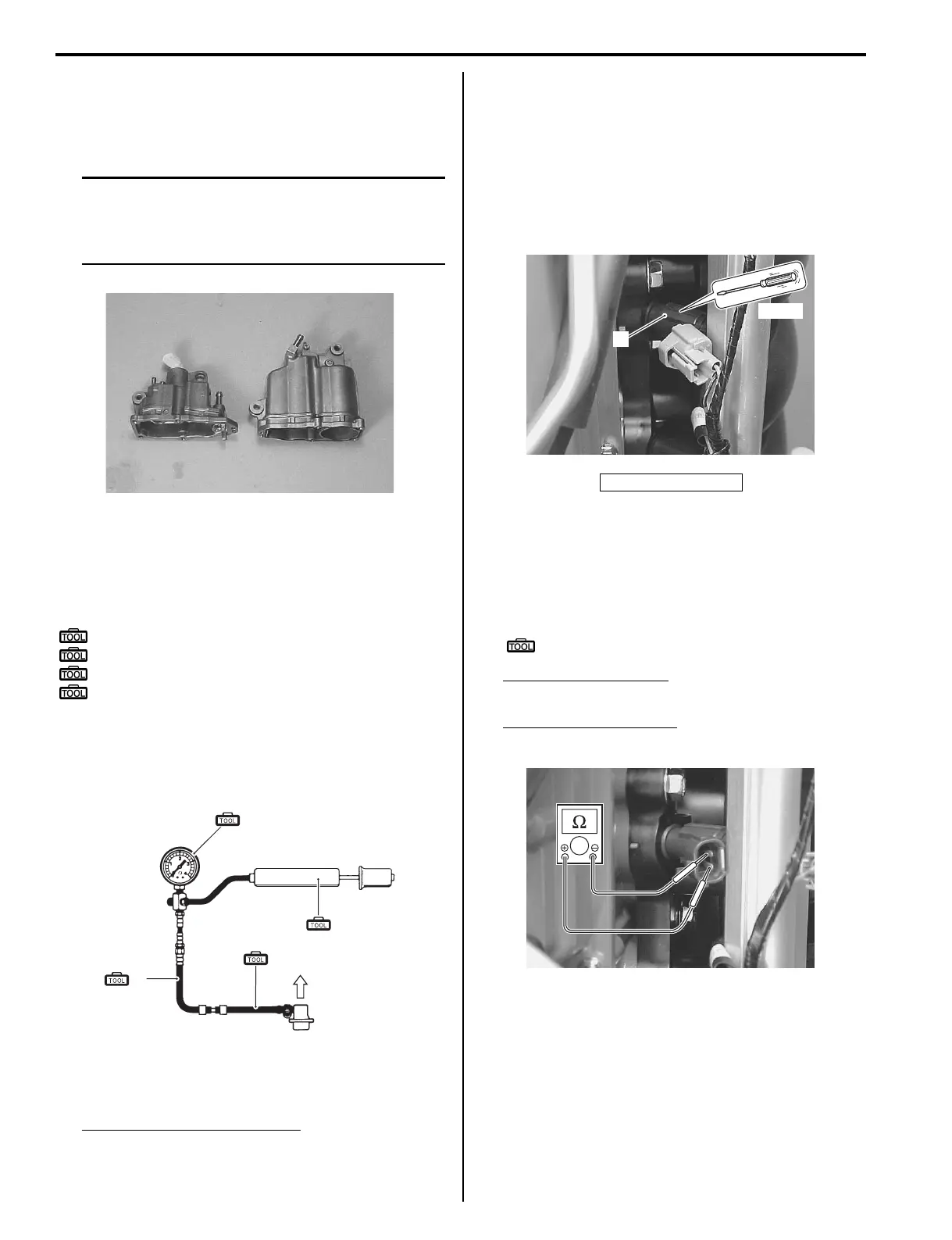

2) Disconnect the lead wire connector from the fuel

injector.

3) Connect a digital tester between the terminals of the

injector and measure resistance.

If out of specification, replace the fuel injector.

Special tool

: 09930–99320 (Digital tester)

Tester knob indication

Resistance (Ω)

Fuel injector resistance

Standard: 10 – 14.0 Ω

4) Connect the lead wire connector to the fuel injector

securely.

I9J011170052-01

(A)

(B)

(C)

(D)

I9J011170021-01

1. Injector body

1

“click”

I9J011170053-03

I9J011170054-01

Loading...

Loading...