0B-8 Maintenance and Tune-Up:

Tappet Clearance Inspection and Adjustment

Z9J0110206041

Inspect tappet clearance

Every 200 hours (12 months)

Inspection

The tappet clearance specification is different for intake

and exhaust valves.

Too small a tappet clearance may reduce engine power,

too large a tappet clearance increases valve noise and

hastens valve and seat wear.

When the tappets are set to the specified clearance, the

engine will run without excessive noise from the valve

mechanism and will deliver full power. In this engine, the

tappet clearance is increased or decreased by replacing

the shim disc, made of a special wear resistant material,

fitted to the top of the tappet. Using the proper tools

provides for easy removal and installation of the shim

disc.

Tappet clearance adjustment should be checked and

adjusted:

• During scheduled periodic inspection.

• When valve mechanism is serviced.

• When camshafts are disturbed by removing them for

inspection.

1) Remove following parts:

• Engine lower side cover.

Refer to “Lower Side Cover Removal and

Installation” in Section 2A (Page 2A-3).

• Ring gear cover.

Refer to “Ring Gear Cover Removal and

Installation” in Section 1D (Page 1D-2).

• Ignition coils and spark plugs.

Refer to “Spark Plug Removal and Installation”

(Page 0B-6) and “Spark Plug Inspection and

Cleaning” (Page 0B-7).

2) Remove the cylinder head cover (1).

Refer to “Cylinder Head Cover Removal and

Installation” in Section 1D (Page 1D-2).

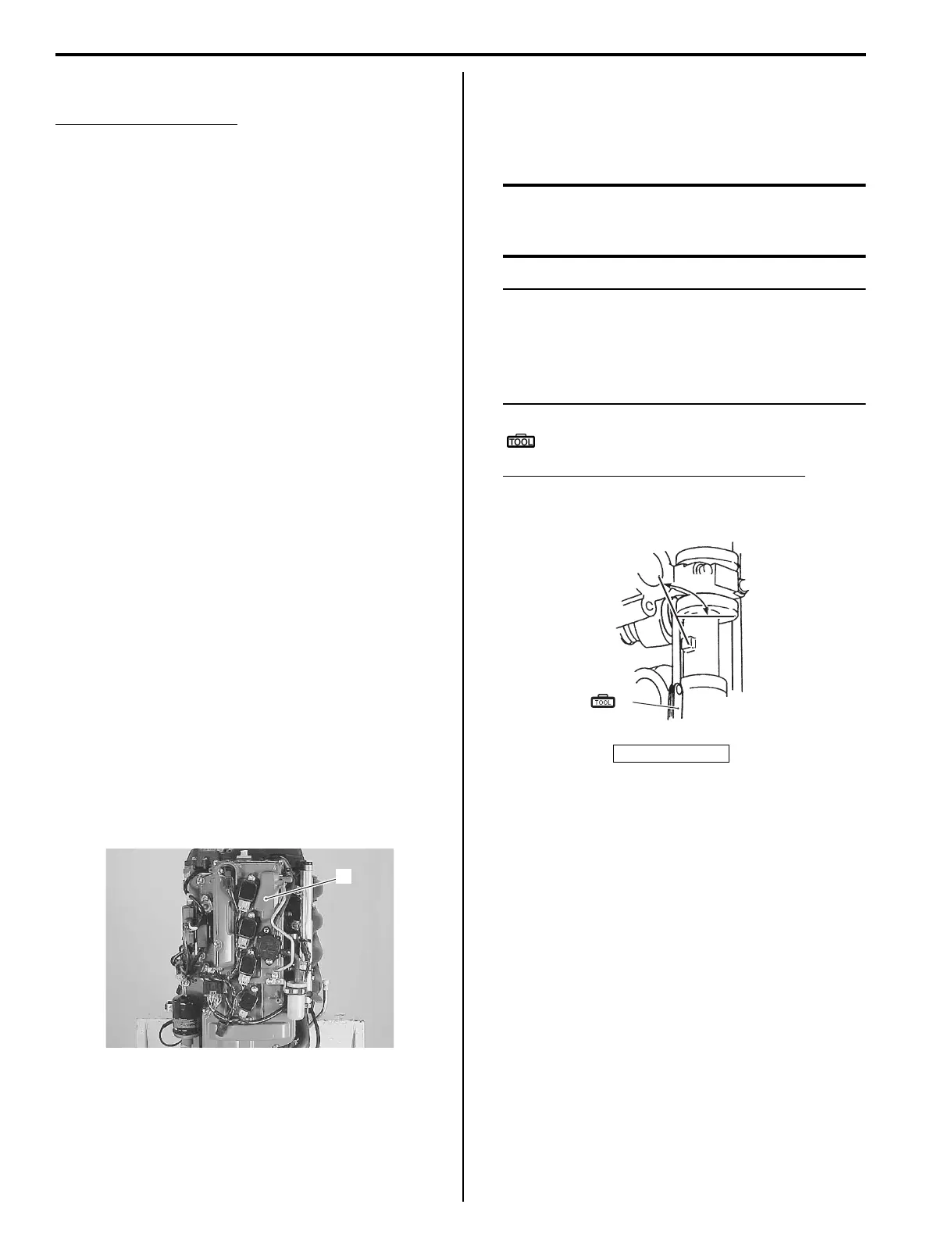

3) Rotate crankshaft counterclockwise to bring cam

nose vertical to shim surface.

4) Measure tappet clearances by inserting thickness

gauge between cam and shim surface.

CAUTION

This is a left hand (LH) rotation powerhead.

Rotate crankshaft counterclockwise to

prevent water pump impeller damage.

NOTE

• Rotate crankshaft and measure clearance

for each tappet respectively by bringing

cam nose vertical to shim surface.

• All tappet clearances can be measured

during two crankshaft rotations.

Special tool

(A): 09900–20803 (Thickness gauge)

Tappet clearance (cold engine condition)

IN.: 0.23 – 0.27 mm (0.009 – 0.011 in.)

EX.: 0.30 – 0.34 mm (0.012 – 0.013 in.)

5) If out of specification, adjust tappet clearance by

changing shim.

1

I9J011020048-01

“a”: 90°

(A)

“a”

I9J011020008-01

Loading...

Loading...