3-27

OPERATION

HANDLING RUBBER TRACKS

Rubber tracks have an inherent weakness,

lack of strength, due to their use of rubber.

Be sure to observe the prohibitions and

cautions below to prevent the tracks from

being damaged or coming off.

PROHIBITIONS

Do not travel or operate the machine in the

following places:

HANDLING RUBBER TRACKS

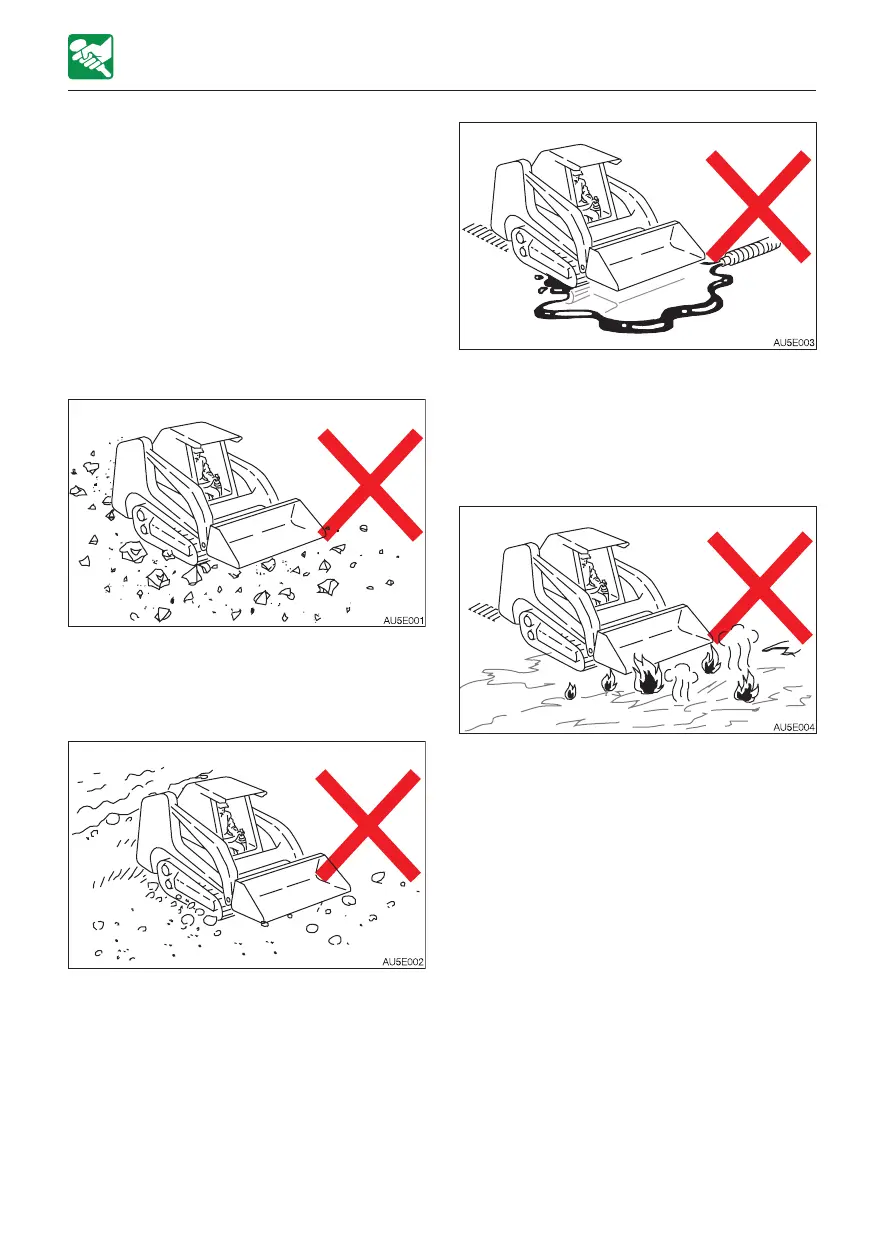

• Traveling and slewing on crushed rock,

extremely rough hard rock, steel beams,

scrap iron, or near the edges of steel plates

will cause damage to the rubber tracks.

• Traveling on riverbeds or places where

there are large numbers of boulders may

cause the stones to get caught and

damage the tracks or make the tracks

come off.

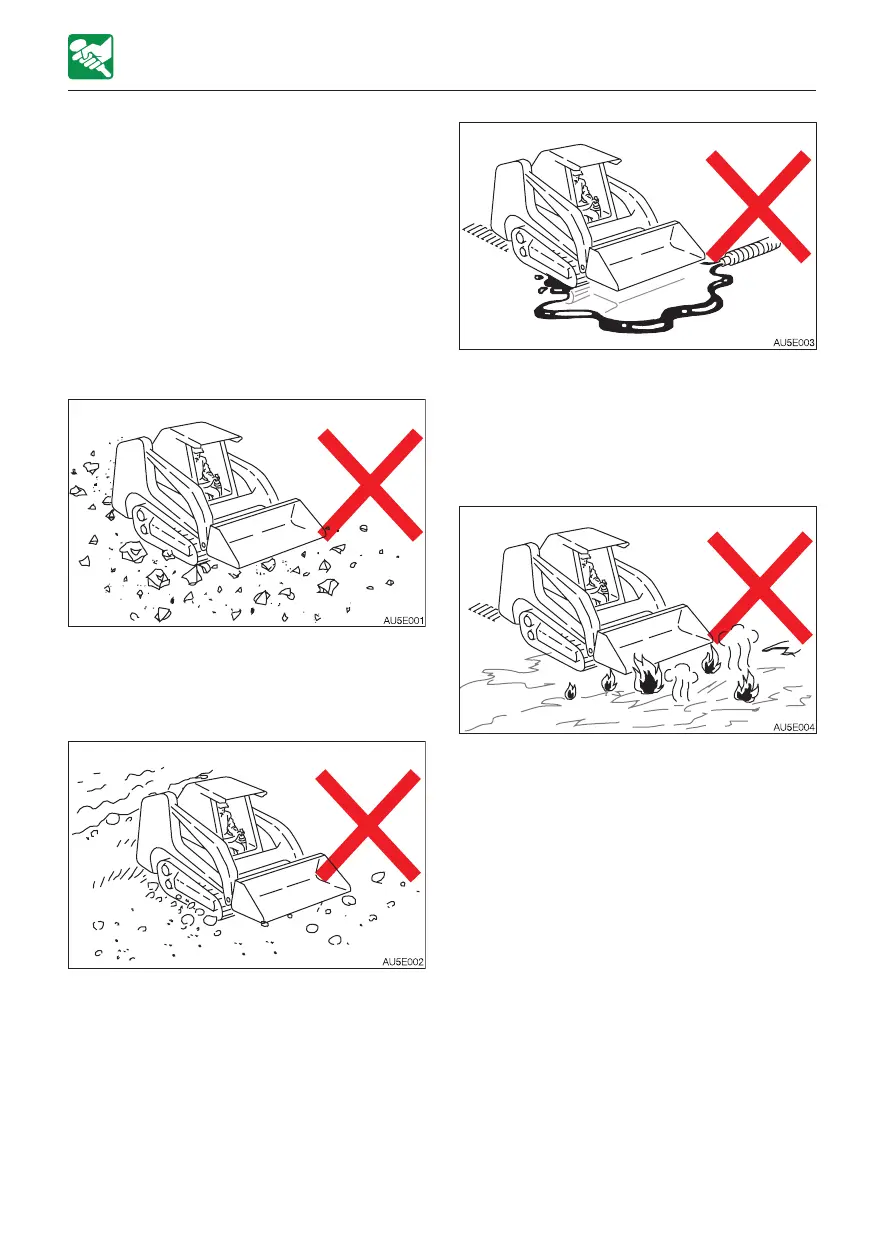

• Do not use the machine on the seashore.

The salt may corrode the steel core.

• Do not let fuel, oil, salt or chemical solvents

get on the tracks. These substances may

corrode the bonding of the steel cores on

the tracks, resulting in rust or peeling. If any

of these substances gets on the tracks,

immediately clean it off with water.

• It will cause an irregular wear or damage to

the lugs, if the machine travels on irregular

surfaces such as recently paved with

asphalt, exposed to a bonfire or of hot iron

sheets under the blazing sun.

• Do not move earth in places where the

rubber tracks may slip. Doing so may

speed up lug wear.

Loading...

Loading...