5-32

MAINTENANCE

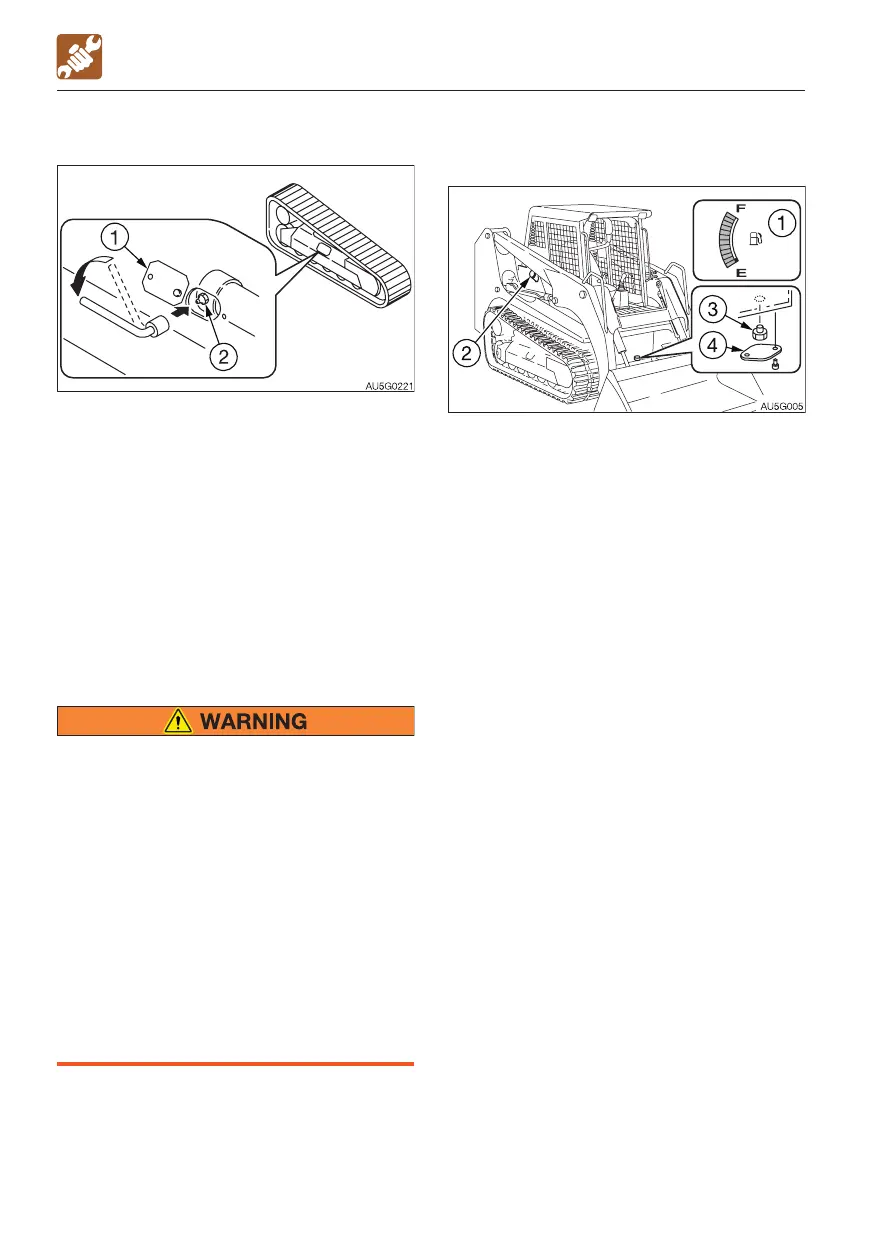

Decreasing the tension

EVERY 50 HOURS

1. Remove the cover (1).

2. Slowly loosen (one turn) the grease

discharge valve (2) with a spanner to

discharge grease. If grease does not

come out well, move the machine back-

and-forth.

3. Tighten the grease discharge valve (2).

· Tightening torque: 59 to 88 N·m (43.5 to

64.9 ft-lb.)

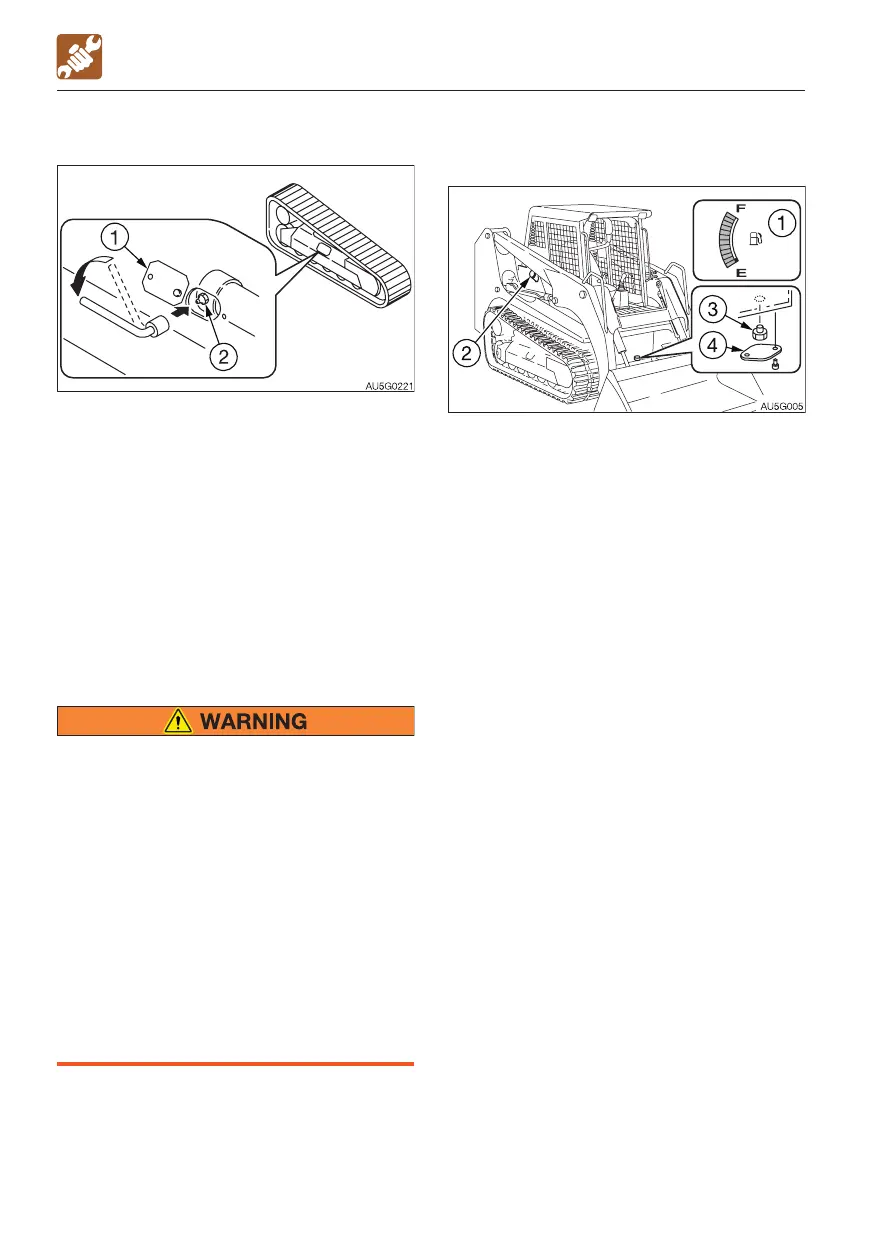

DRAINING THE WATER FROM THE FUEL

TANK

• Do not smoke or permit open flames

while handling fuel or working on the

fuel system.

• Never remove the fuel cap or add fuel

when the engine is running or still hot.

Do not spill fuel on the hot surface of

the machine.

• Fill the fuel tank in a well ventilated

place.

• Do not fill the fuel tank to capacity.

Allow room for oil expansion.

• Clean up spilled fuel immediately.

• Securely tighten the fuel filler cap.

• Use the correct grade of fuel for the

operating season.

Do the draining operation before starting the

machine.

1. Remove the fuel filler cap (2).

2. Remove the cover (4).

3. Place a pan under the drain valve (3).

4. Open the drain valve (3) and drain the

water and sediment buildup in the bottom

of the tank.

5. Close the drain valve (3) and install the

cover (4).

6. Add fuel while watching the fuel gauge (1).

7. Tighten the fuel filler cap (2) and lock it.

8. Bleed air.

Bleeding air from the fuel system

Refer to “Bleeding air from the fuel system”

on page 6-9.

Note: Air in the fuel system causes the

engine to fail to start or to have problems.

Bleed air when the fuel tank is emptied,

using the same procedure above.

Loading...

Loading...