5

5-33

4st 4/5/6 2011

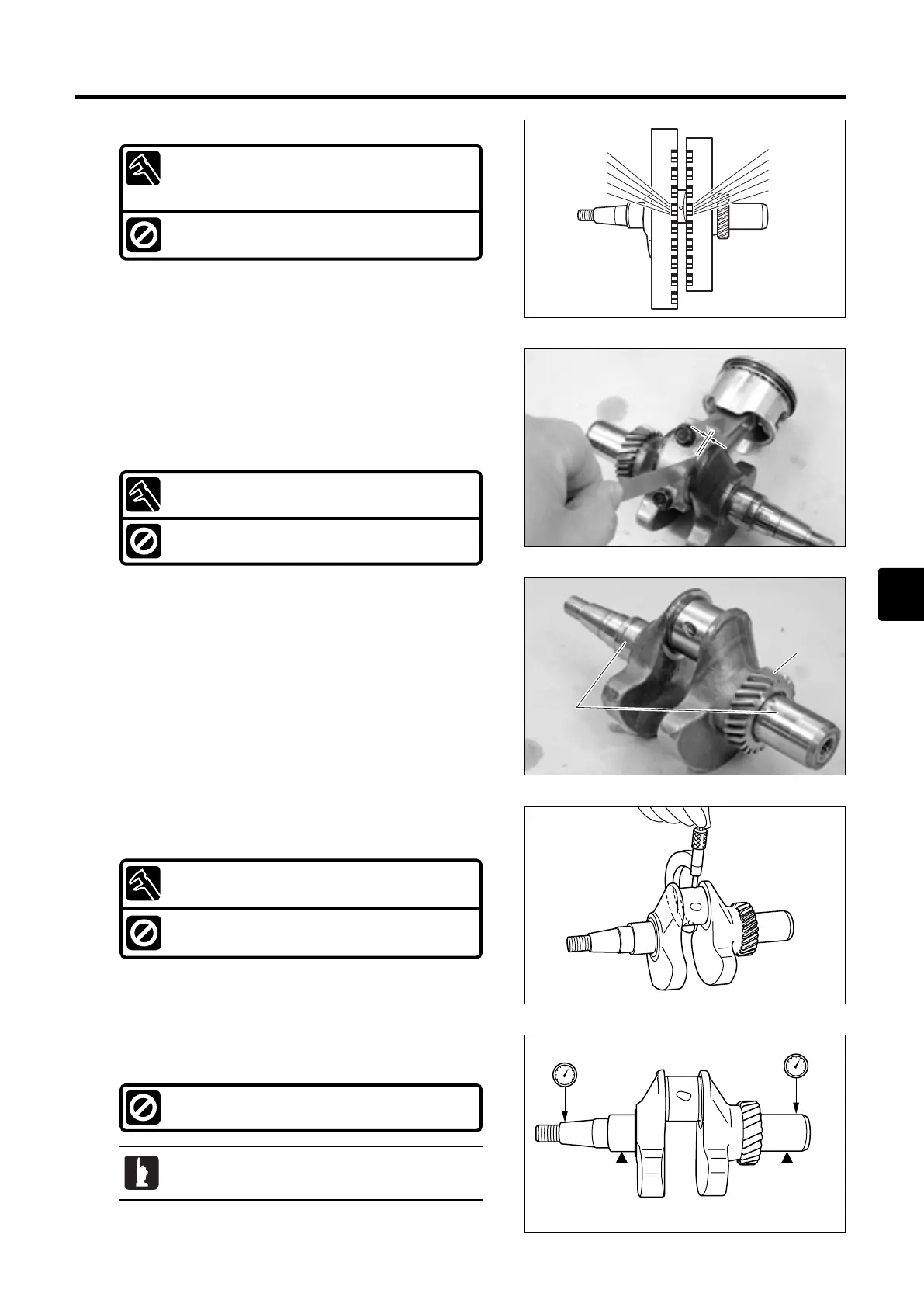

mm in

0.051

0.076

0.102

0.127

0.152

0.002

0.003

0.004

0.005

0.006

4. Remove connecting rod and measure plastic gauge.

Connecting rod big end and crankshaft clearance:

corresponding value

0.040

-

0.066 mm (0.00157

-

0.00260 in)

Functional Limit :

0.08 mm (0.00315 in)

11

22

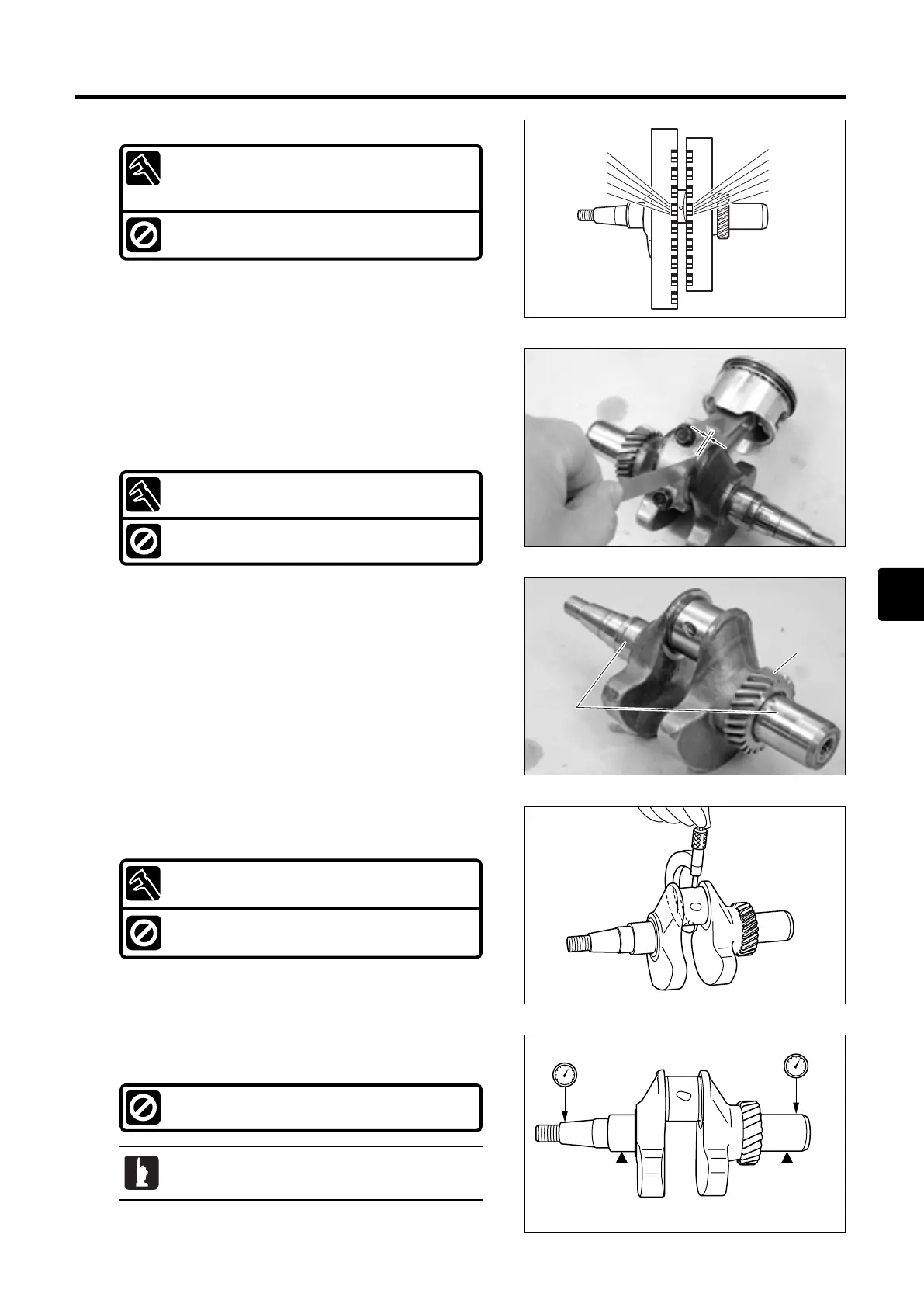

27) Inspection of Connecting Rod Big

End Side Clearance

1. Measure connecting rod big end side clearance a by

using a commercially available thickness gauge. Replace

connecting rod and/or crank shaft if the clearance is over

specified value.

Connecting Rod Big End Side Clearance a :

0.20 - 0.40 mm (0.0079 - 0.0157 in)

Functional Limit :

0.70 mm (0.0276 in)

28) Inspection of Crank Shaft

1. Check crank shaft gear 1 and bearing 2 for damage and

wear. Replace crank shaft ass'y or bearing if necessary.

2. Measure crank pin outer diameter. Replace crank shaft if

outer diameter is less than specified value.

Crank Pin Outer Diameter : Standard value

29.95 mm (1.1791 in)

Functional Limit :

29.92 mm (1.1780 in)

3. Measure crank shaft runout. Replace crank shaft or

bearing if outer diameter is less than specified value.

Crank Shaft Runout Limit :

0.05 mm (0.0020 in)

Use V blocks to support crank shaft at bearings.

MFS4-5-6Ech05110425.qxd11.4.2511:39AM ページ33

Loading...

Loading...