Fuel (continued)

Biodiesel

Type This machine can also use a biodiesel-blended fuel of up to B20

(20% biodiesel, 80% petroleum diesel).

The petroleum diesel portion should be low or ultra low sulfur.

Use B5 (biodisel content of 5%) or lesser blends in cold weather

Minimum Cetane Rating 40

Biodiesel Precautions Painted surfaces may be damaged by biodiesel blends.

Monitor seals, hoses, gaskets in contact with fuel as they may

degrade over time.

Fuel filter plugging may be expected for a time after converting to

biodiesel blended.

For more information on biodiesel, contact your authorized Toro

distributor.

Storage Acquire only enough clean, fresh diesel fuel or biodiesel fuel that

you will consume within 180 days. Do not use fuel that has been

stored for more than 180 days.

Oil and additives Do not add to the fuel

Biodiesel fuel must meet:

Standard Location

ASTM D6751 USA

EN 14214 European Union

Blended fuel must meet:

ASTM D975 USA

EN 590 European Union

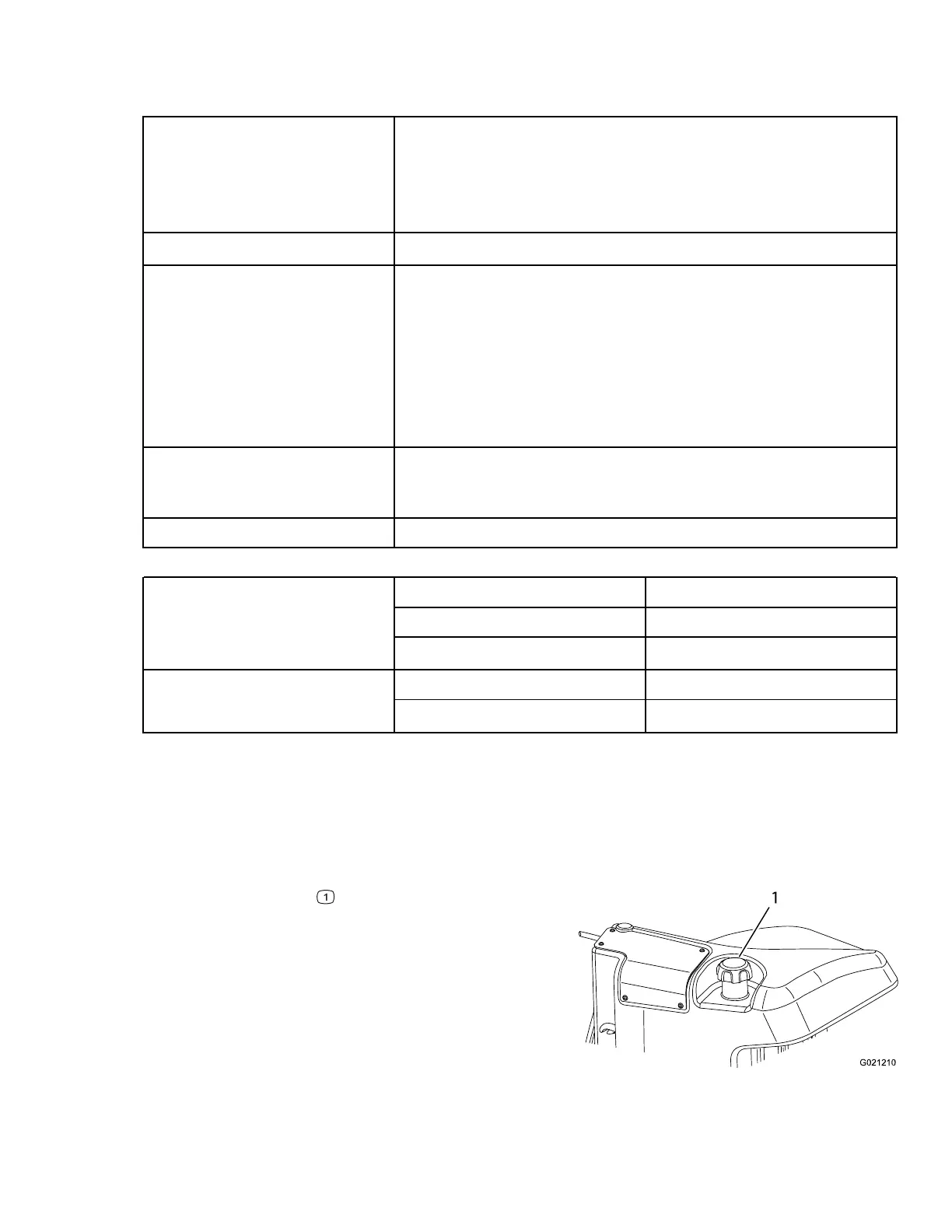

Adding Fuel

1. Park the machine on a level surface, lower the cutting units, shut off the engine, and

remove the key.

2. Using a clean rag, clean the area around the fuel-tank cap.

G438846

3. Remove the cap from the fuel tank.

4. Fill the tank until the level is to the bottom of

the filler neck with diesel fuel.

5. Secure the fuel-tank cap.

Note: If possible, fill the fuel tank after each

use. This minimizes possible buildup of

condensation inside the fuel tank.

3464-478A Page 5–2 Operation: Before Operation

Loading...

Loading...