RTHD-SVX02H-EN 101

Periodic Maintenance

Overview

This section describes preventative maintenance proce-

dures and intervals for the Series R unit. Use a periodic

maintenance program to ensure optimal performance

and efficiency of the Series R units.

An important aspect of the chiller maintenance program

is the regular completion of the “Series R Operating

Log”; an example of this log is provided in this manual.

When filled out properly the completed logs can be re-

viewed to identify any developing trends in the chiller’s

operating conditions.

For example, if the machine operator notices a gradual

increase in condensing pressure during a month’s time,

he can systematically check for and then correct, the pos-

sible cause(s) of this condition (e.g., fouled condenser

tubes, non-condensables in the system).

Weekly Maintenance and Checks

After the unit has operated for approximately 30 minutes

and the system has stabilized, check the operating condi-

tions and complete the procedures below:

• Log the chiller.

• Check evaporator and condenser pressures with

gauges and compare to the reading on the Clear Lan-

guage Display. Pressure readings should fall within

the following ranges specified in the Operating Con-

ditions.

Note: Optimum condenser pressure is dependent on

condenser water temperature, and should equal

the saturation pressure of the refrigerant at a tem-

perature 2 to 5°F above that of leaving condenser

water at full load.

Monthly Maintenance and Checks

• Review operating log.

• Clean all water strainers in both the chilled and con-

densing water piping systems.

• Measure the oil filter pressure drop. Replace oil filter

if required. Refer to “Service Procedures”.

• Measure and log the subcooling and superheat.

• If operating conditions indicate a refrigerant short-

age, leak check the unitan confirm using soap bub-

bles.

• Repair all leaks.

• Trim refrigerant charge until the unit operates in the

conditions listed in the note below.

Note: ARI conditions are: condenser water: 85°F and 3

GPM per ton and evaporator water: 54-44°F.

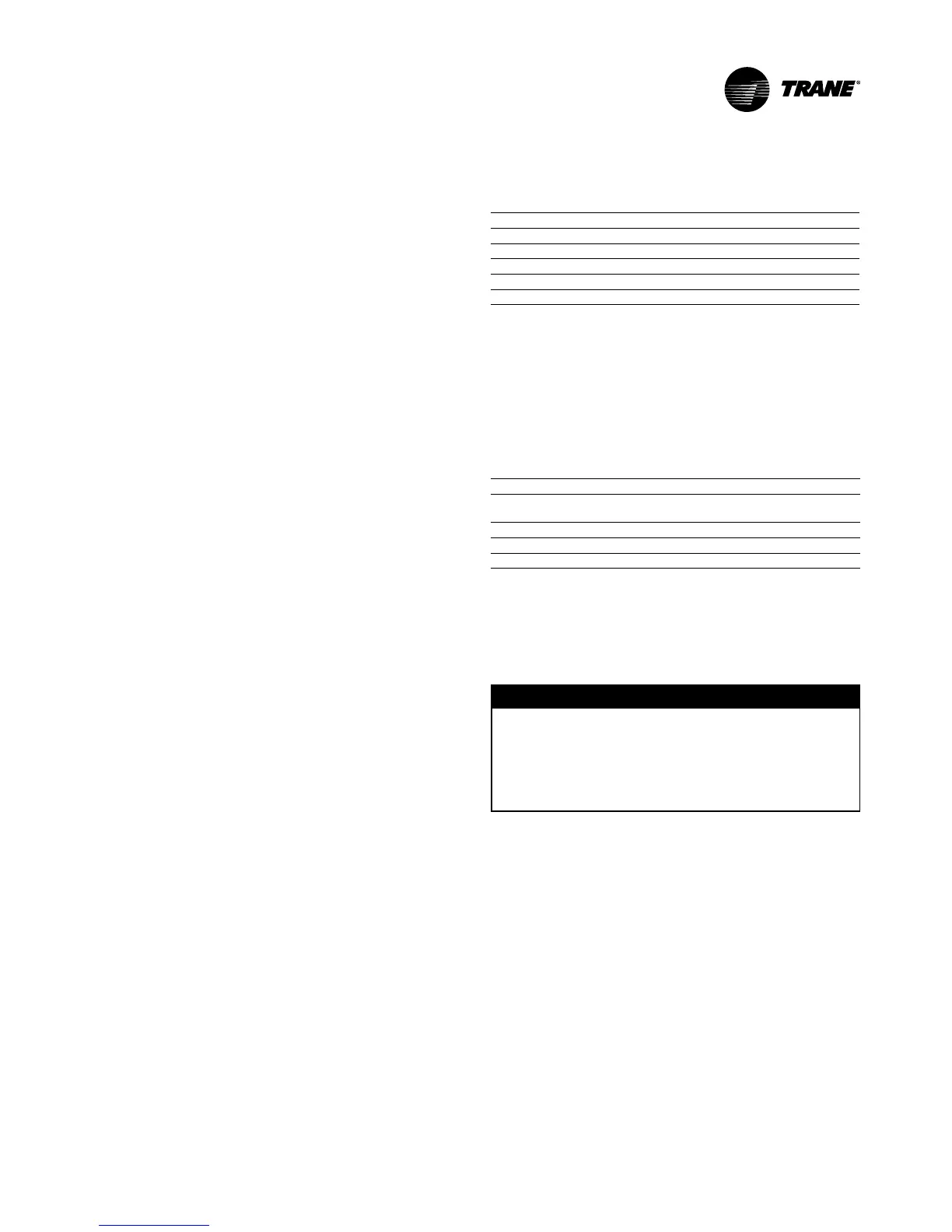

Table 31. Operating Conditions at Full Load

Description Condition

Evaporator pressure 40-55 psig

Condensing pressure 85-120 psig

Discharge superheat 17

°

F

Subcooling 5-10

°

F

EXV percent open 40-50% open in Auto mode

All conditions stated above are based on the unit running fully load-

ed, running at ARI conditions.

• If full load conditions can not be met. Refer to note

below to trim the refrigerant charge.

Note: Conditions at minimum must be: entering con-

denser water: 85°F and entering evaporator water:

55°F.

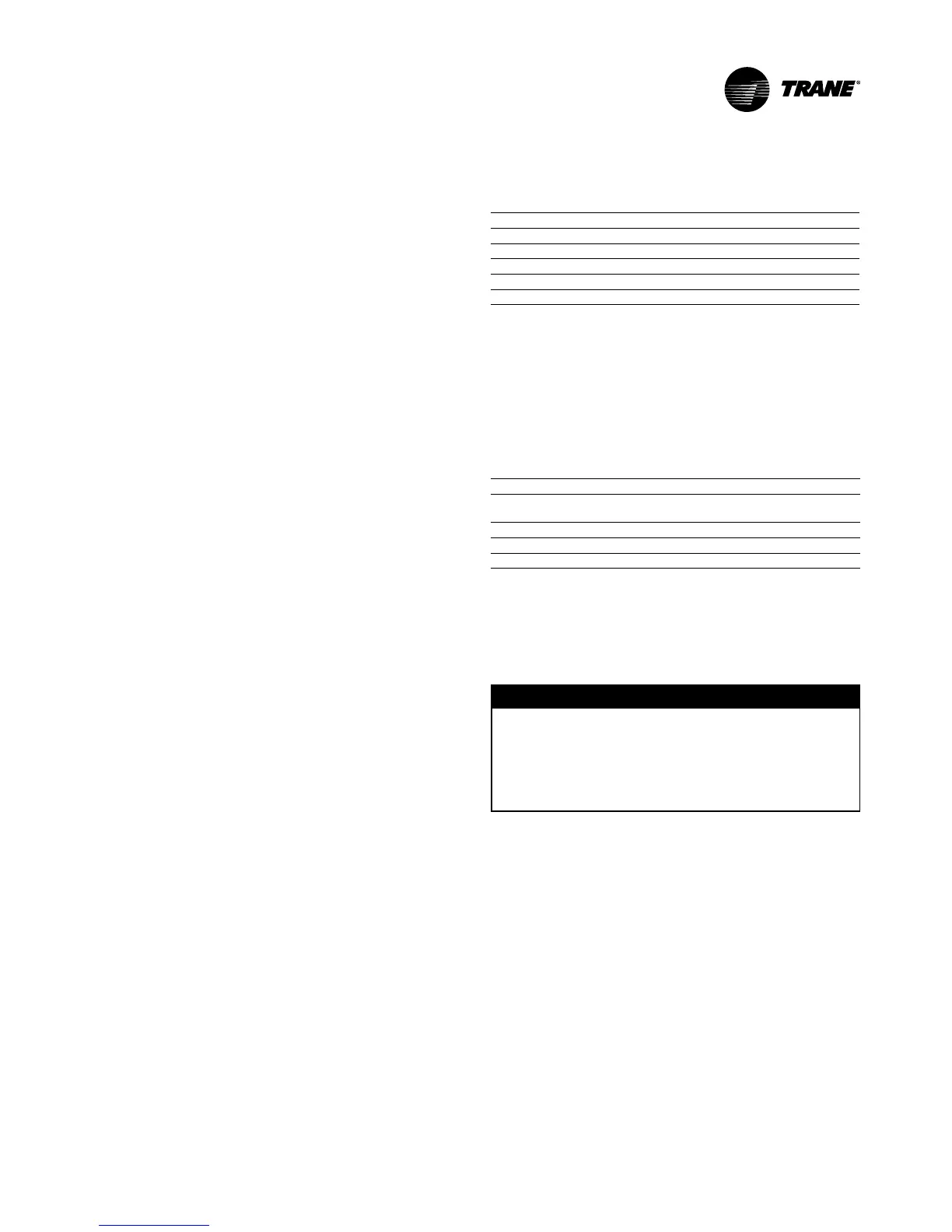

Table 32. Operating Conditions at Minimum Load

Description Condition

Evaporator approach *less than 7

°

F (non-glycol

applications)

Condensing approach *less than 7

°

F

Subcooling 2-3

°

F

EXV percent open 10-20 % open

*≈1.0

°

F for new unit.

Annual Maintenance

Shut down the chiller once each year to check the follow-

ing:

D

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote discon-

nects before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be inadver-

tently energized. Failure to disconnect power before

servicing could result in death or serious injury.

• Perform all weekly and monthly maintenance proce-

dures.

• Check the refrigerant charge and oil level. Refer to

“Maintenance Procedures”. Routine oil changing is

not necessary on a hermetic system.

• Have a qualified laboratory perform an oil analysis to

determine system moisture content and acid level.

Note: IMPORTANT: Due to the hygroscopic properties

of the POE oil, all oil must be stored in metal

containers. The oil will absorb water if stored in a

plastic container

• Check the pressure drop across the oil filter. Refer to

“Maintenance Procedures”.

• Contact a qualified service organization to leak check

the chiller, to inspect safety controls, and inspect

electrical components for deficiencies.

• Inspect all piping components for leakage and/or

Loading...

Loading...