Installation Mechanical

34 RTHD-SVX02H-EN

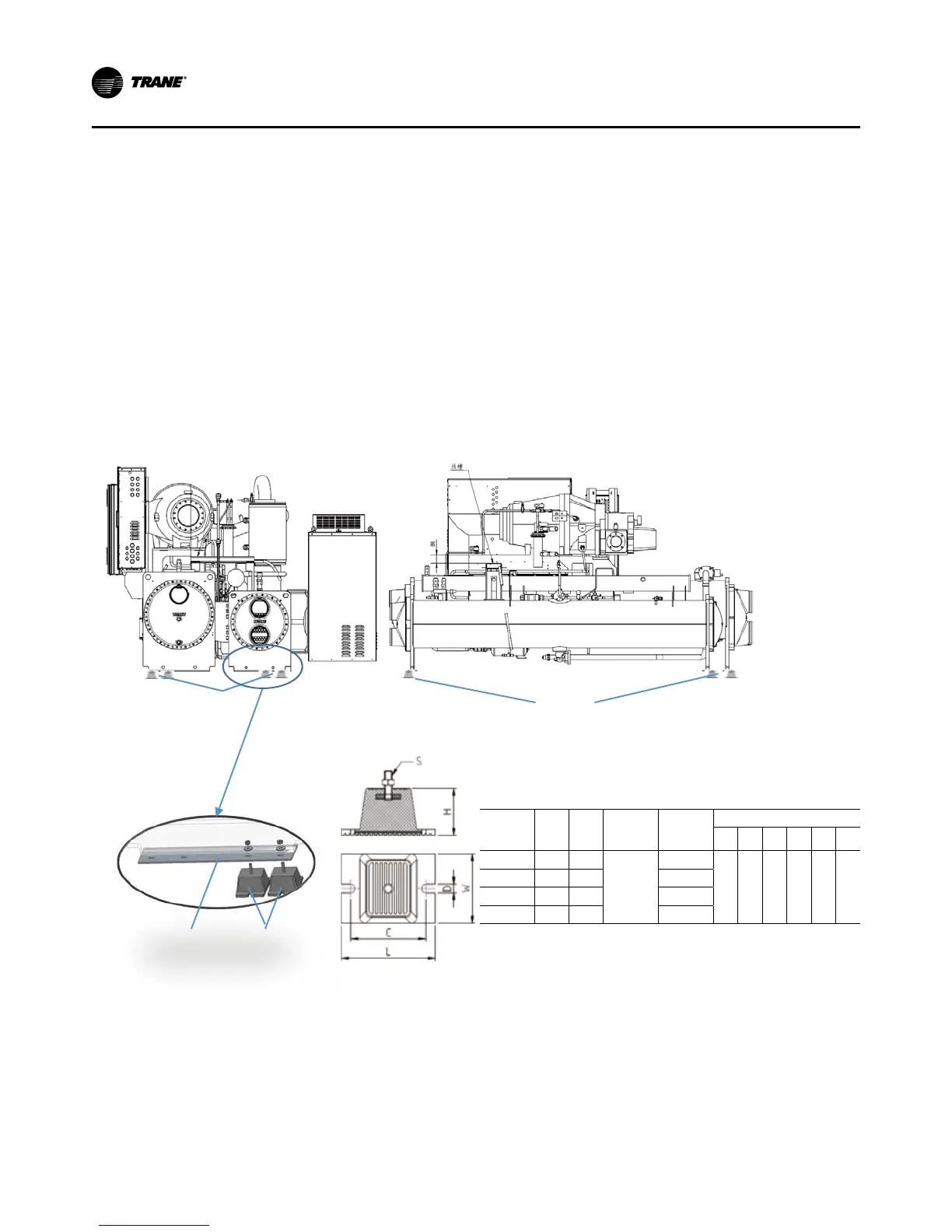

Figure 11. Isolator Pad Placement

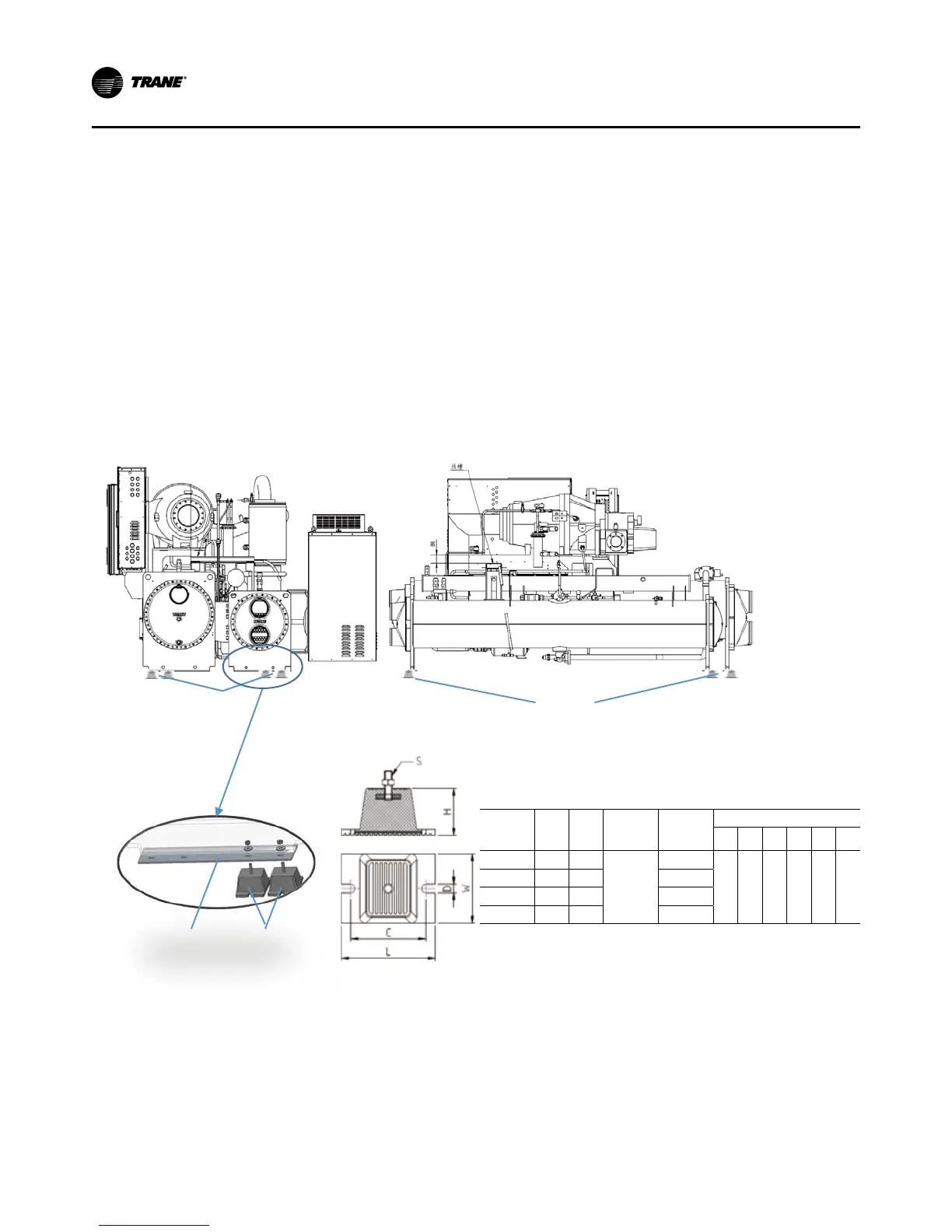

Technical data of rubber AVM

Model

Load

(kg)

Load

(Lbs)

Deection

(±3mm)

Vertical

Rigidity

(kg/mm)

Outer Size(±2mm)

L W H C ØD S

HA-700 700 1543

12

58.33

159 118 70 127 14 M12

HA-1000 1000 2205 83.33

HA-1400 1400 3086 116.67

HA-1800 1800 3968 150.00

Bottom plate

Isolator

Isolator

Isolator

9. The unit is shipped with four spacers (only three on

B family) on the compressor mount that protect the

compressor isolation pads during shipping and in

handling. Remove these spacers (Figure 12) before

the unit is operated.

10. Remove the shipping brackets from the bottom sides

of the oil separator(s) (see Figure 12).

Note: Once shipping bracket(s) is removed, the oil sep-

arator is only supported by the discharge line.

Placement Neoprene Isolator Installation

(optional)

8. Install the optional neoprene isolators at each mount-

ing location.

8.1. Secure the isolators to the mounting surface,

using the mounting slots in the isolator base

plate, as shown as below. Do not fully tighten

the isolator mounting bolts at this time.

8.2. Align the mounting holes in the base of the unit,

with the threaded positioning pins on the top of

the isolators.

8.3. Lower the unit on to the isolators and secure the

isolator to the unit with a nut. Maximum isolator

deflection should be approximately 1/4”.

8.4. Level the unit carefully. Refer to “Leveling”. Fully

tighten the isolator mounting bolts.

8.5. Two Isolators for each foot, refer to Figure 11 ,

total 8 isolators installed for one chiller.

Loading...

Loading...