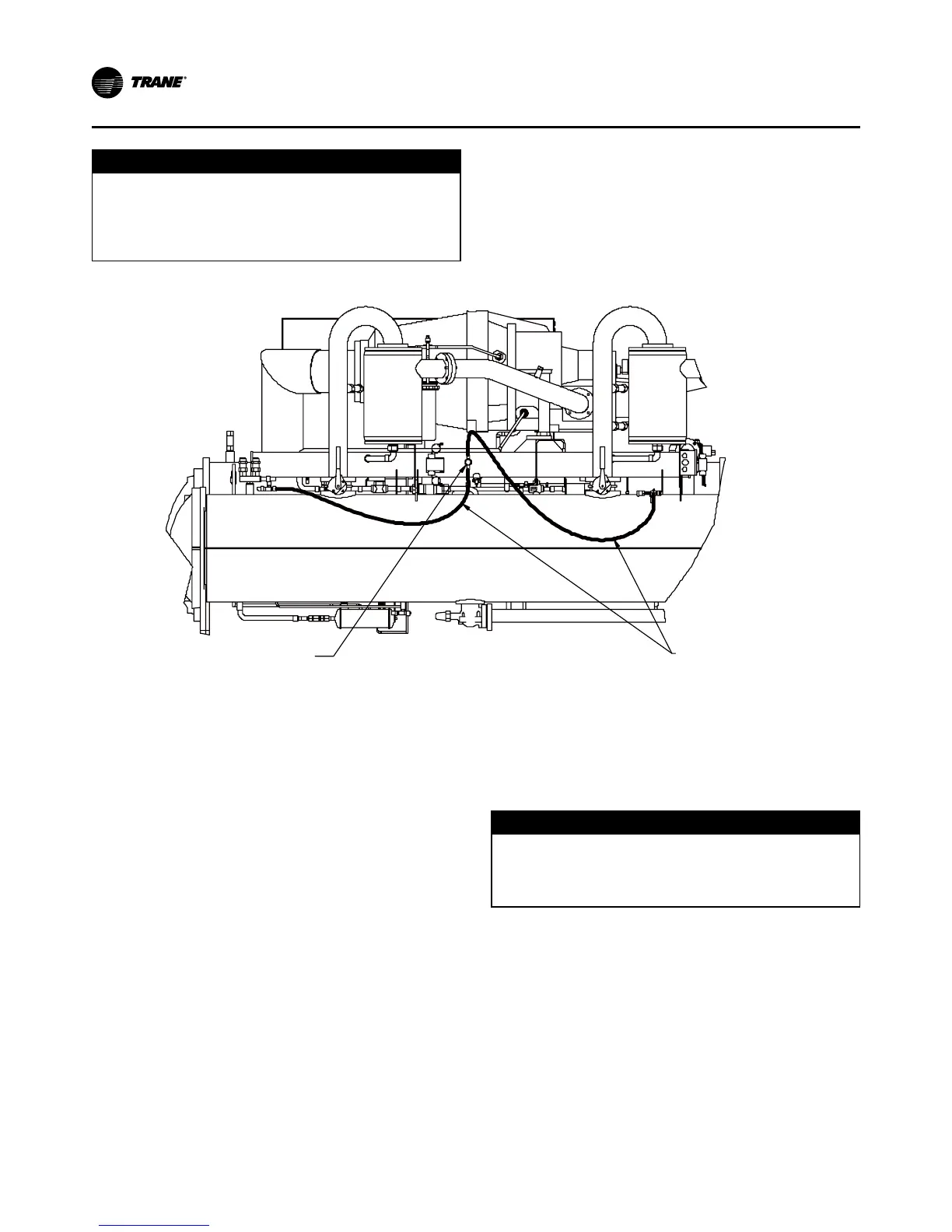

3. Attach a 3/8” or 1/2” hose with a sightglass in the

middle to the oil sump drain valve and the condenser

service valve at the top of the condenser.

Using high pressure rated clear hose with appropri-

ate fittings can help speed up the process.

4. After the unit is off line for 10 minutes, move the

sightglass along the side of the oil sump.

5. The level should be between 2” and 5” from the bot-

tom of the oil sump. If the level appears to be above 8”,

the oil sump is completely full. Most likely more oil

resides in the rest of the system and some oil needs

to be removed until the level falls between 2” and 5”

in the oil sump.

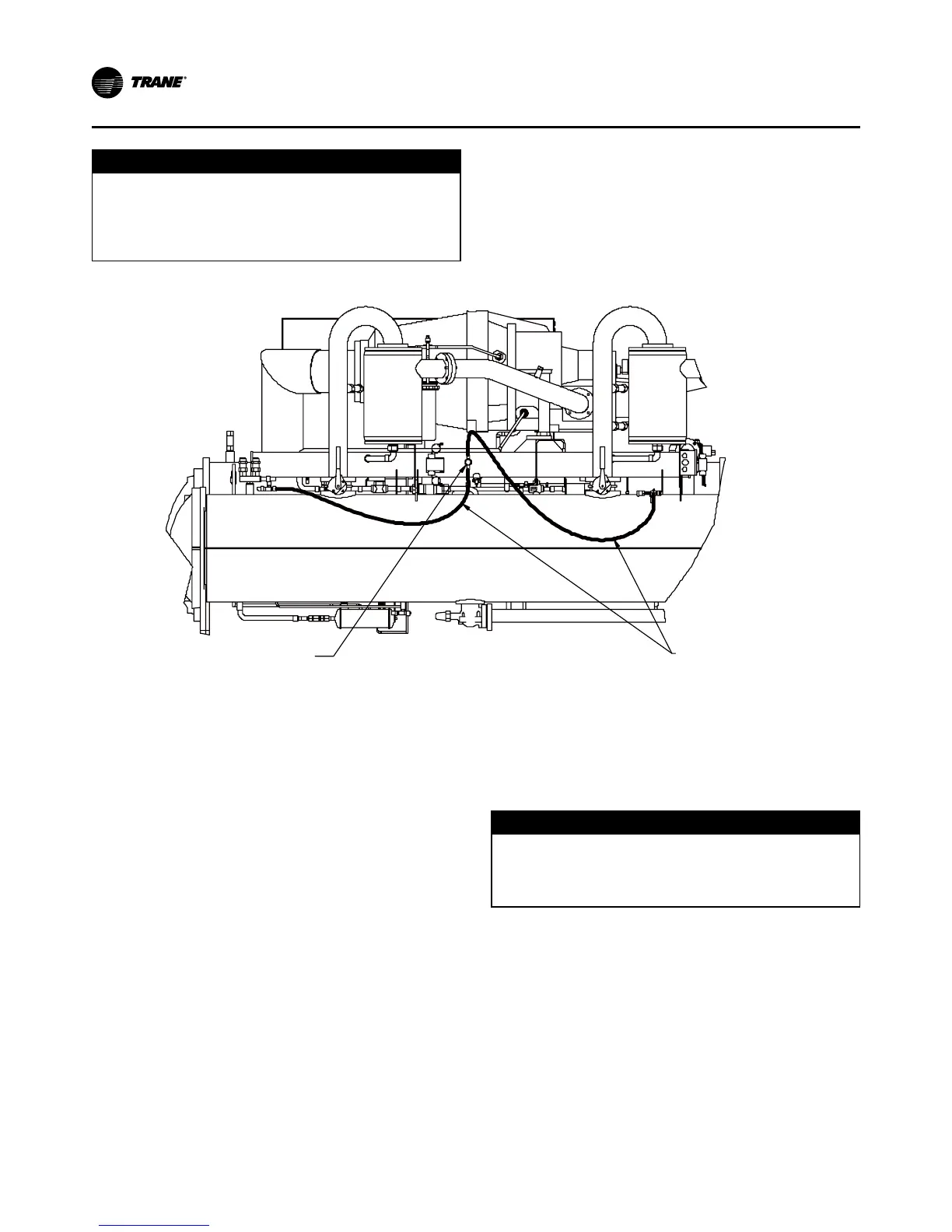

6. If the level is below 2”, there is not enough oil in the

sump. This can occur from not enough oil in the

system or more likely, oil migration to the evapora-

tor. Oil migration can occur from a low refrigerant

charge, gas pump malfunction, etc.

Note: If the oil is logged in the evaporator confirm the

operation of the gas pump. If the gas pump is not

functioning properly all oil will be logged in the

evaporator.

7. After the level is determined, close the service valves

and remove the hose/sightglass assembly.

Removing Compressor Oil

The oil in the compressor oil sump is under a constant

positive pressure at ambient temperature. To remove oil,

open the service valve located on the bottom of the oil

sump and drain the oil into a suitable container using

the procedure outlined below:

D

CAUTION

POE Oil!

Due to the hygroscopic properties of the POE oil, all oil

must be stored in metal containers. The oil will absorb

water if stored in a plastic container.

Oil should not be removed until the refrigerant is isolat-

ed or removed.

8. Connect a line to the oil sump drain valve.

9. Open the valve and allow the desired amount of oil

to flow into the container and close the charging

valve.

10. Measure the exact amount of oil removed from the

unit.

Oil Charging Procedure

It is critical to fill the oil lines feeding the compressor

Loading...

Loading...