6-2 Electrostatic Classifier Model 3082 and SMPS Spectrometer Model 3938

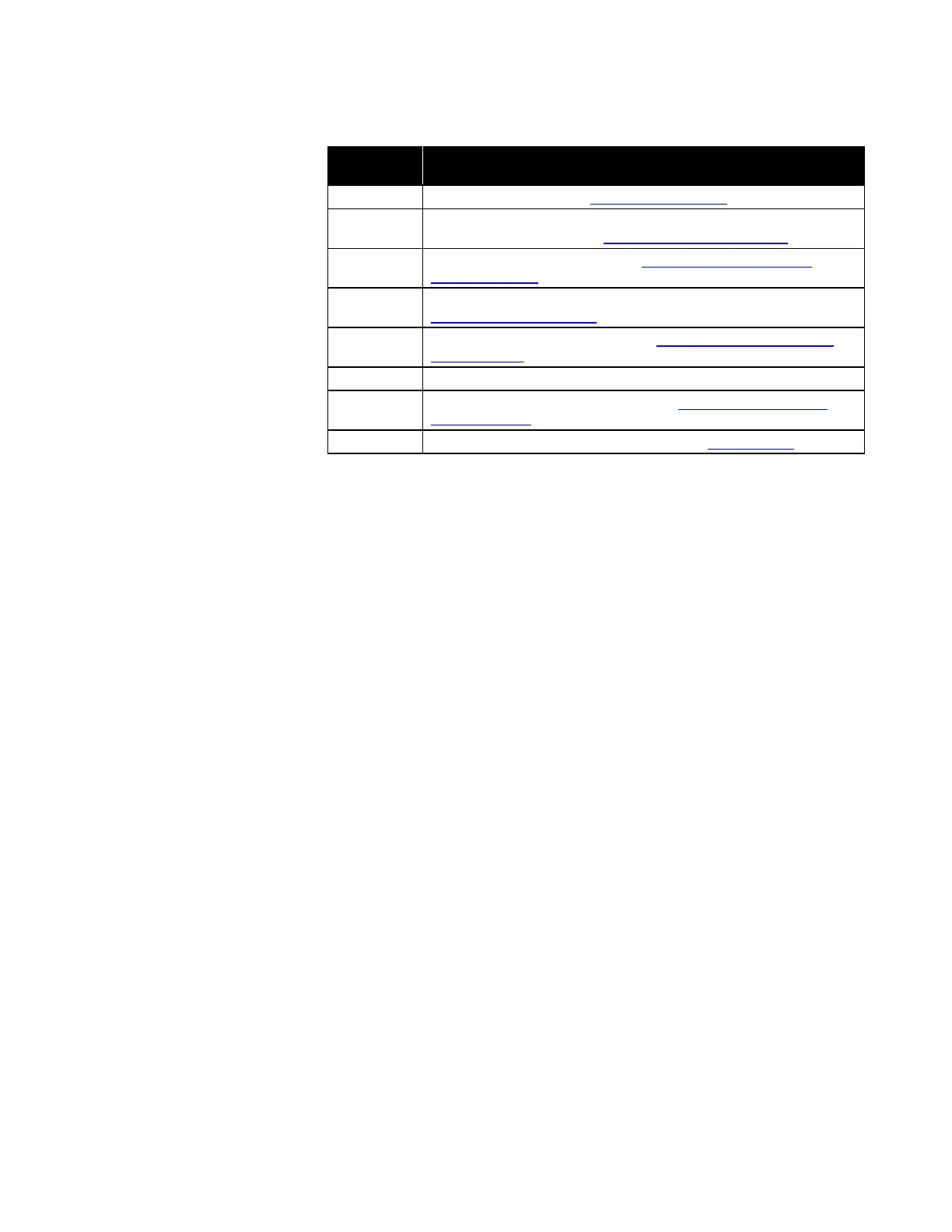

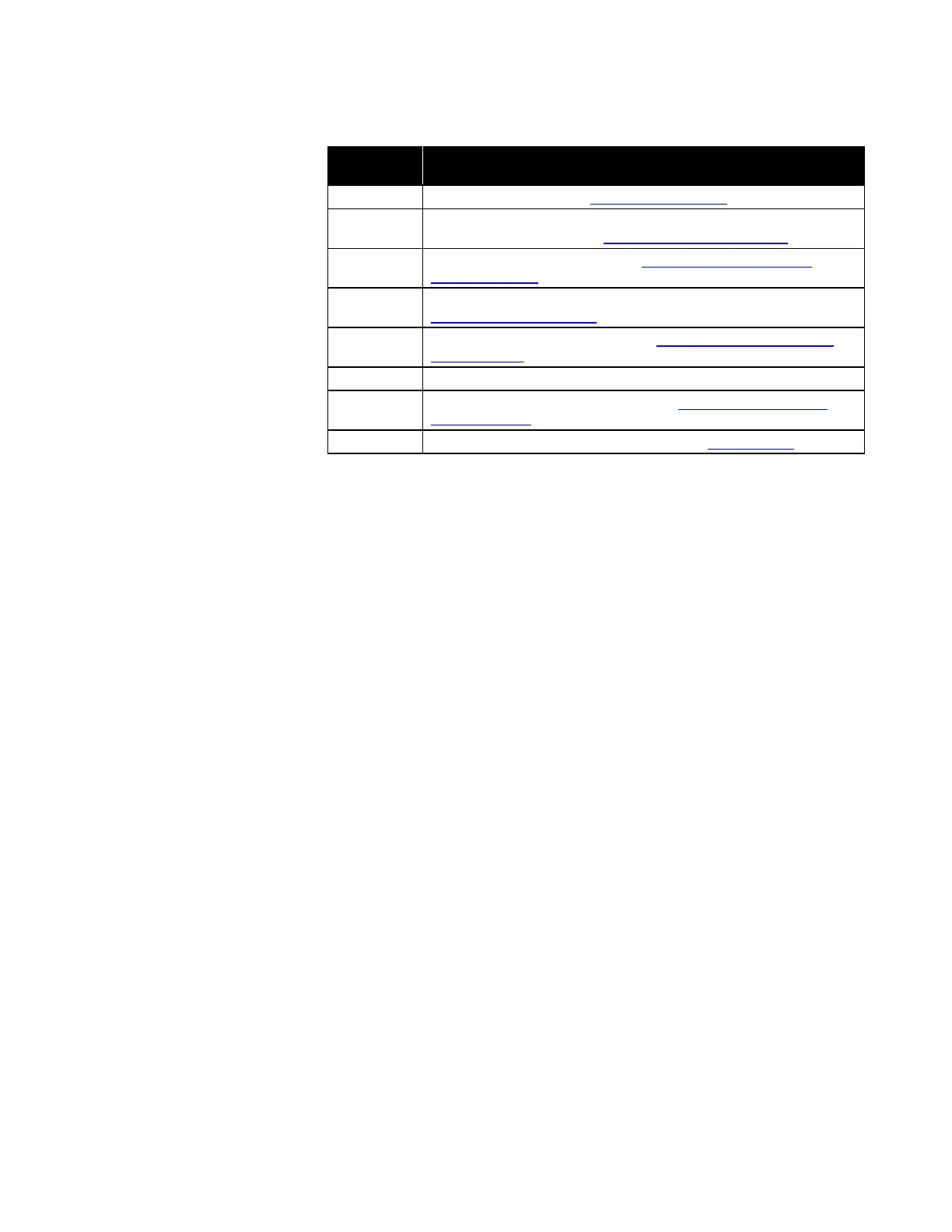

Table 6-2

Electrostatic Classifier Maintenance Schedule

Clean the impactor. (See Cleaning the Impactor, below)

Clean the mobility analyzer center rod and outer electrode in the

Electrostatic Classifier (see Cleaning the DMA Electrodes, below)

Perform O-ring maintenance (see Replacing Impactor O-rings and

Greasing O-rings, below)

Replace the filter cartridges in the Electrostatic Classifier (See

Replacing the Inline Filters, below)

Clean the DMA Dacron screen (see Cleaning/Changing the DMA

Dacron Screen, below)

Clean the neutralizer (See separate neutralizer manuals)

Calibrate the classifier sheath flow (see Chapter 5, Performing a

User Calibration).

Replace CPC filter cartridges (See separate CPC manuals)

Recommended Cleaning Solutions

The external surfaces of the 3082 may require cleaning time-to-time.

Isopropanol or soapy water can be used to clean the classifier (display,

chassis, impactor, DMA). Dampen a cloth with cleaning solution to apply.

In order to prevent dripping or overspray into instrument, do not spray on.

Do not use any abrasive materials, aromatic solvents (toluene, xylene), or

ketonic solvents (ketone or acetone) as these may cause damage to the

display and/or the painted chassis.

Cleaning the Impactor

The primary purpose of the impactor is removal of particles above a

specific size. Over time, particle loading on the impaction plate influences

the pressure drop across the nozzle and; therefore, particle measurements

due to particle re-entrainment. The impactor must; therefore, be cleaned at

intervals of 5 to 50 hrs, depending upon the inlet aerosol particle

concentration.

To clean the impactor, follow these instructions:

1. Grasp the impactor, twist counterclockwise, and pull it out of the

aerosol inlet.

Loading...

Loading...