29

VERSION 06/2018

ORDER NUMBER DOC 2343275

8.2.4 FFKM DOSING VALVE: TOPPING UP OR CHANGING SEPARATING AGENT

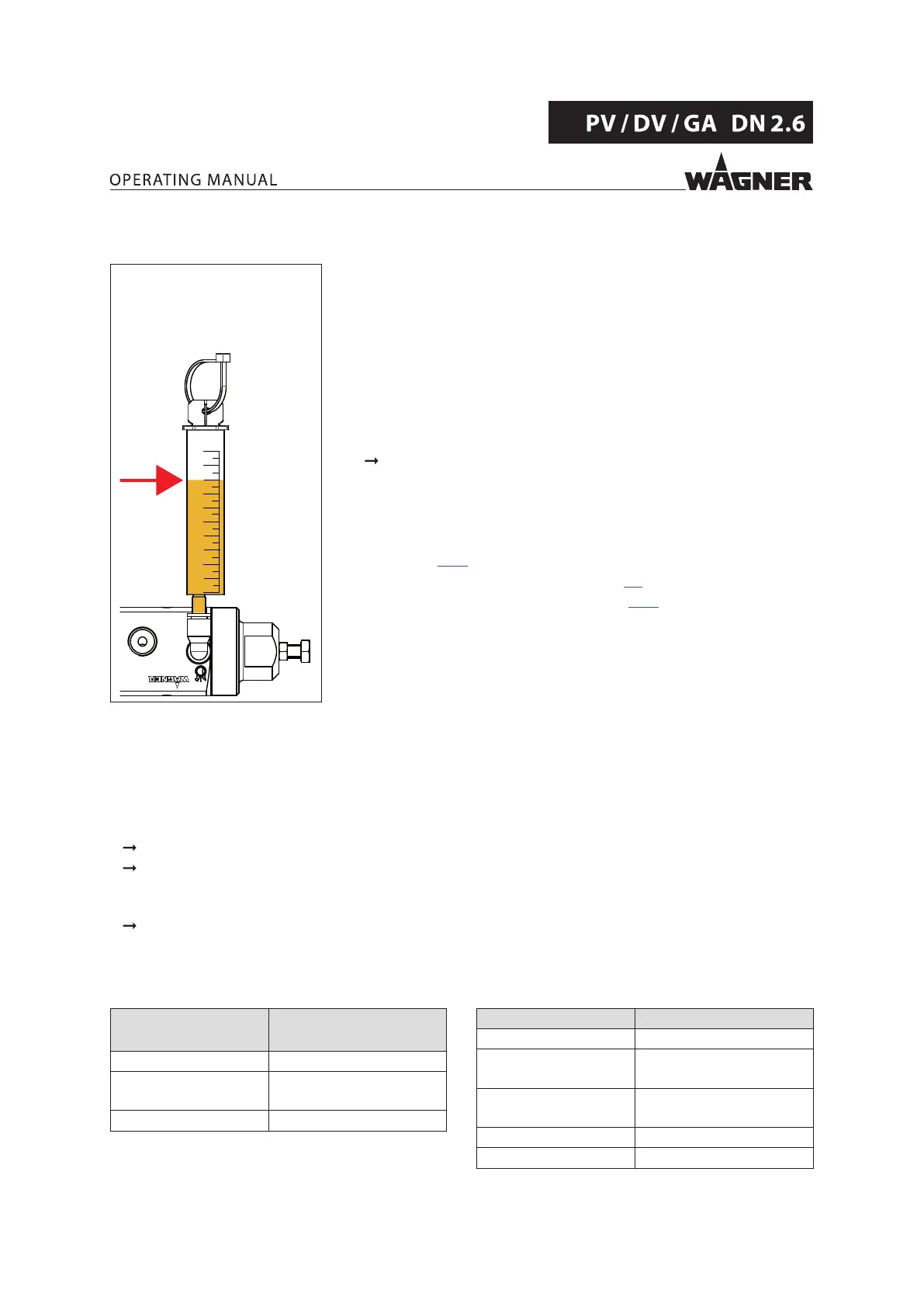

Normal lling level

At a normal lling level, the

separating agent level in the

tank has to lie at the "8" mark.

B_07235

2

4

6

8

10

ml

Topping up separating agent

In case of level deviations, pull the piston out of

the separating agent container. Top up separating

agent and reinsert piston.

Changing the separating agent

In the case of soiled separating agent or if foam

caused by air bubbles is observed or when the

separating agent container's piston is pushed out/

falls down:

Replace separating agent and valve rod seals:

1. Empty the separating agent container.

2. Completely unscrew the separating agent

supply.

3. Dismount the valve in accordance with

Chapter 9.5.2.

4. Cleaning in accordance with Chapter 9.6.

5. Assembly in accordance with Chapter 9.7.3.

6. Use the spray device to ll separating agent

directly into the leakage holes. Move the valve

rod briey backwards and forwards.

7. Completely mount the separating agent

supply.

8. Fill separating agent in the separating agent

container to level "8". Reinsert piston.

8.2.5 PRODUCT HOSES, PIPES AND COUPLINGS

The service life of the complete hoses between product pressure generator and application

device is reduced due to environmental inuences even when handled correctly.

Check hoses, pipes, and couplings every day and replace if necessary.

Additionally, the operator must regularly check the complete hoses for wear and

tear as well as for damage at intervals that he/she has set. Records of these checks

must be kept.

Undamaged complete hoses are to be replaced at the latest when one of the two

following intervals has been exceeded:

− 6 years from the date of the hose crimping (see tting embossing).

− 10 years from the date of the hose imprinting.

Fitting embossing

Meaning

(if present)

xxx bar Pressure

yymm

Crimping date (year/

month)

XX Internal code

Hose imprinting Meaning

WAGNER Name / Manufacturer

yymm

Date of manufacture

(year/month)

xxx bar (xx MPa)

e.g., 270 bar (27 MPa)

Pressure

XX Internal code

DNxx (e.g., DN10) Nominal diameter

Loading...

Loading...