XO FLEX – Installation instructions Checking the unit

50

Fit the test flowmeter (FA-400) to

the micromotor.

Lift the micromotor forward.

Check the cooling air pressure.

Activate the configuration button

under the bridge twice within one

second (see

Figure 66).

Adjustment of cooling air to 10

l/min.

Activate

to increase pressure.

Activate

to decrease pressure.

Activate ◄ to save value.

Place the micro motor on the

instrument bridge again.

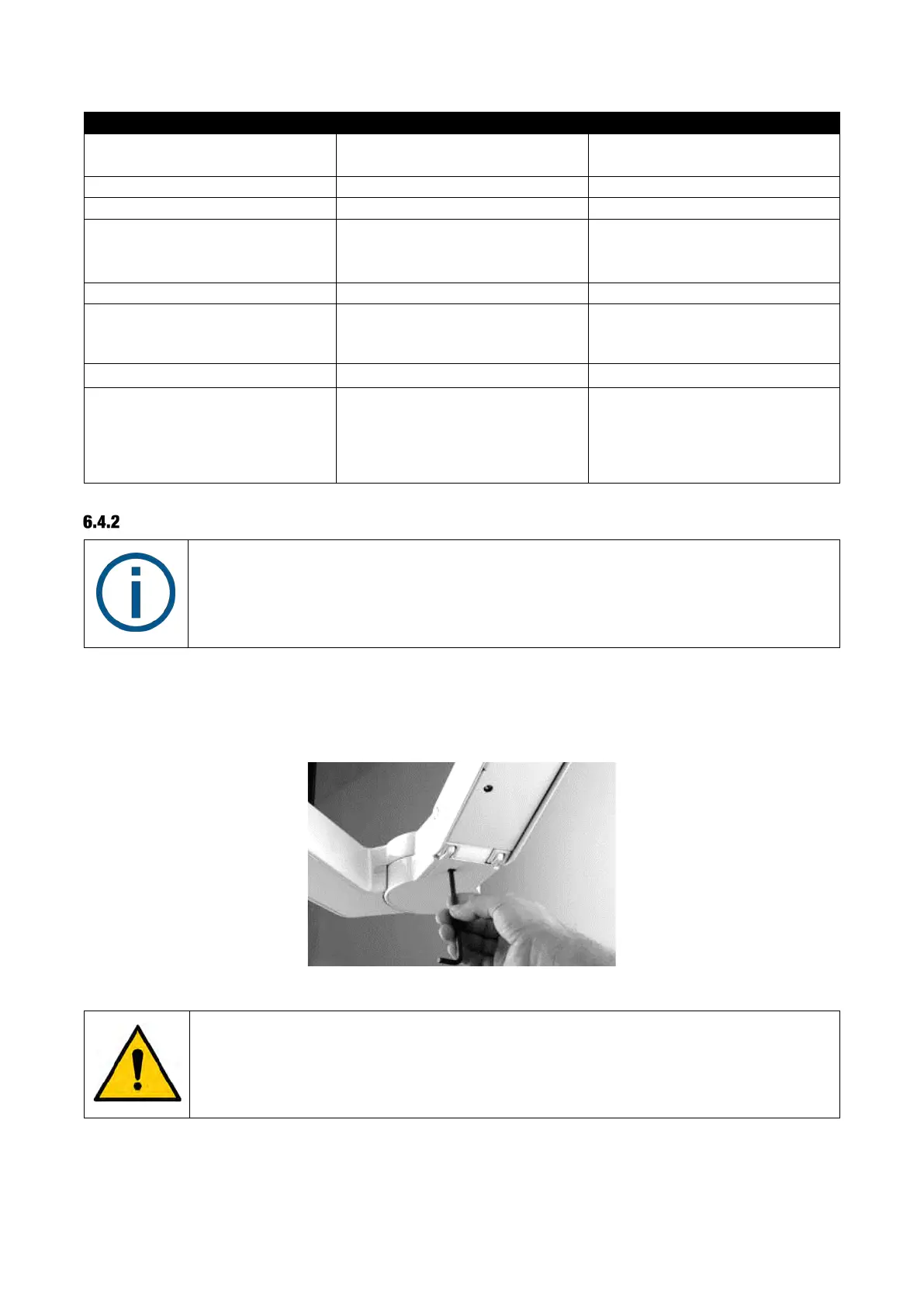

ADJUSTING THE BALANCE SPRING AND FRICTION BRAKE IN THE BRIDGE FOREARM

When all instruments – incl. handpieces – are fitted to the bridge and the hand

instrument table carries the “normal” load (maximum load on instrument table is 1.5

kg):

• The instrument bridge should be in balance in all positions and

• It should be easy to maneuver with “two fingers”

1. Move the instrument bridge to the highest, middle and lowest positions.

2. Adjust the balance spring with a 6 mm Allen key as shown in Figure 68.

3. If necessary, adjust friction at the specified load and adjust with 4 mm Allen key as shown in

Figure 69.

Figure 68 – Adjusting the balance spring in the bridge forearm

Do not tighten the friction brakes too much!

If the brake is too tight it may result in a mechanical hazard!

If it is not possible to keep the arms in balance without overtightening the brakes, the

unit is not in level and the steps described in section 5.2.5 should be followed to level

the unit.

Loading...

Loading...