268 AO2000 CONTINUOUS GAS ANALYZERS | OI/AO2000-EN REV. B

Checking gas path seal integrity

When should gas paths checked for seal integrity?

Gas path seal integrity should be checked periodically. It must be verified

after the gas paths inside or outside the gas analyzer have been opened (e.g.

after removing or installing an analyzer module).

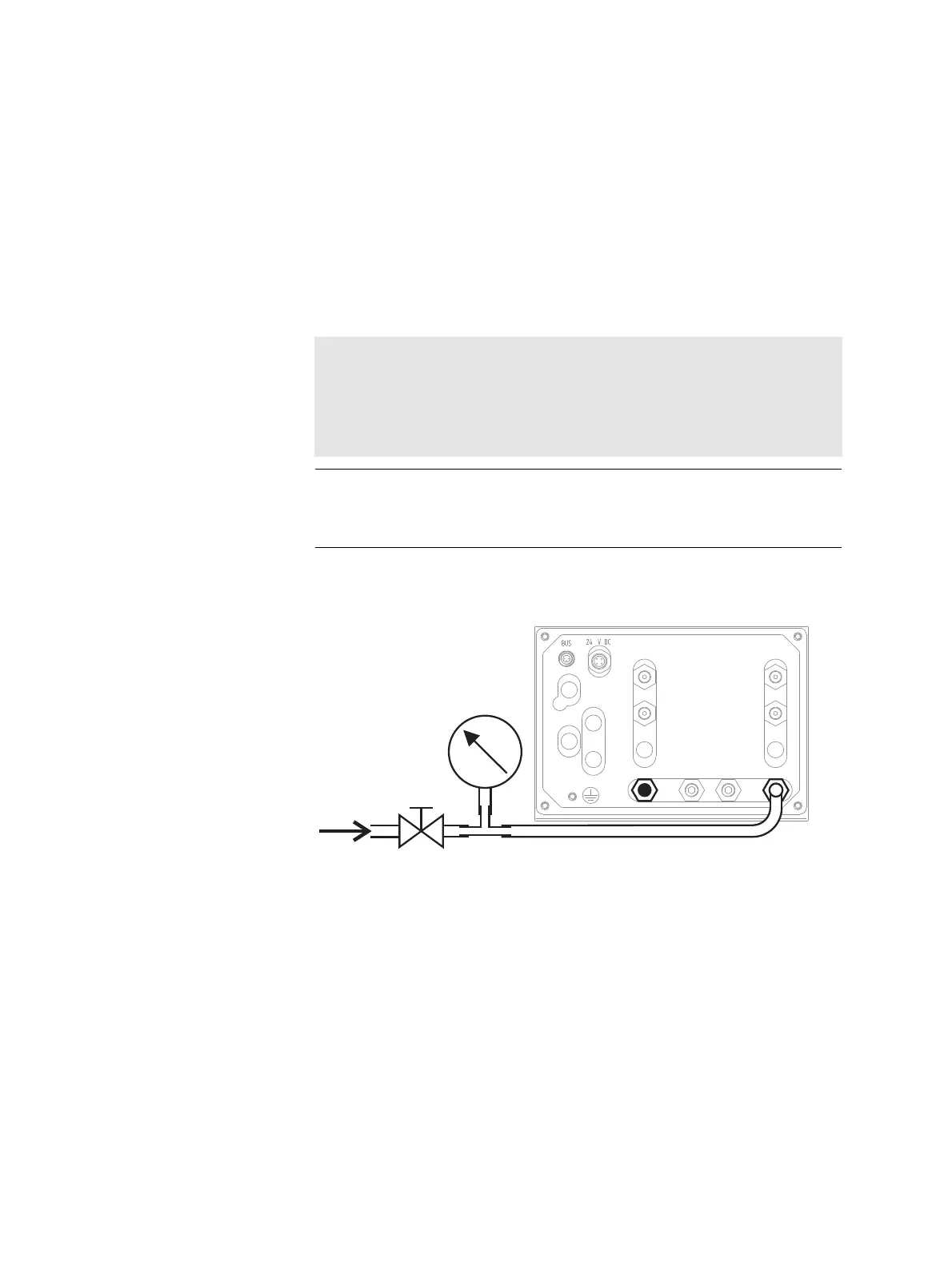

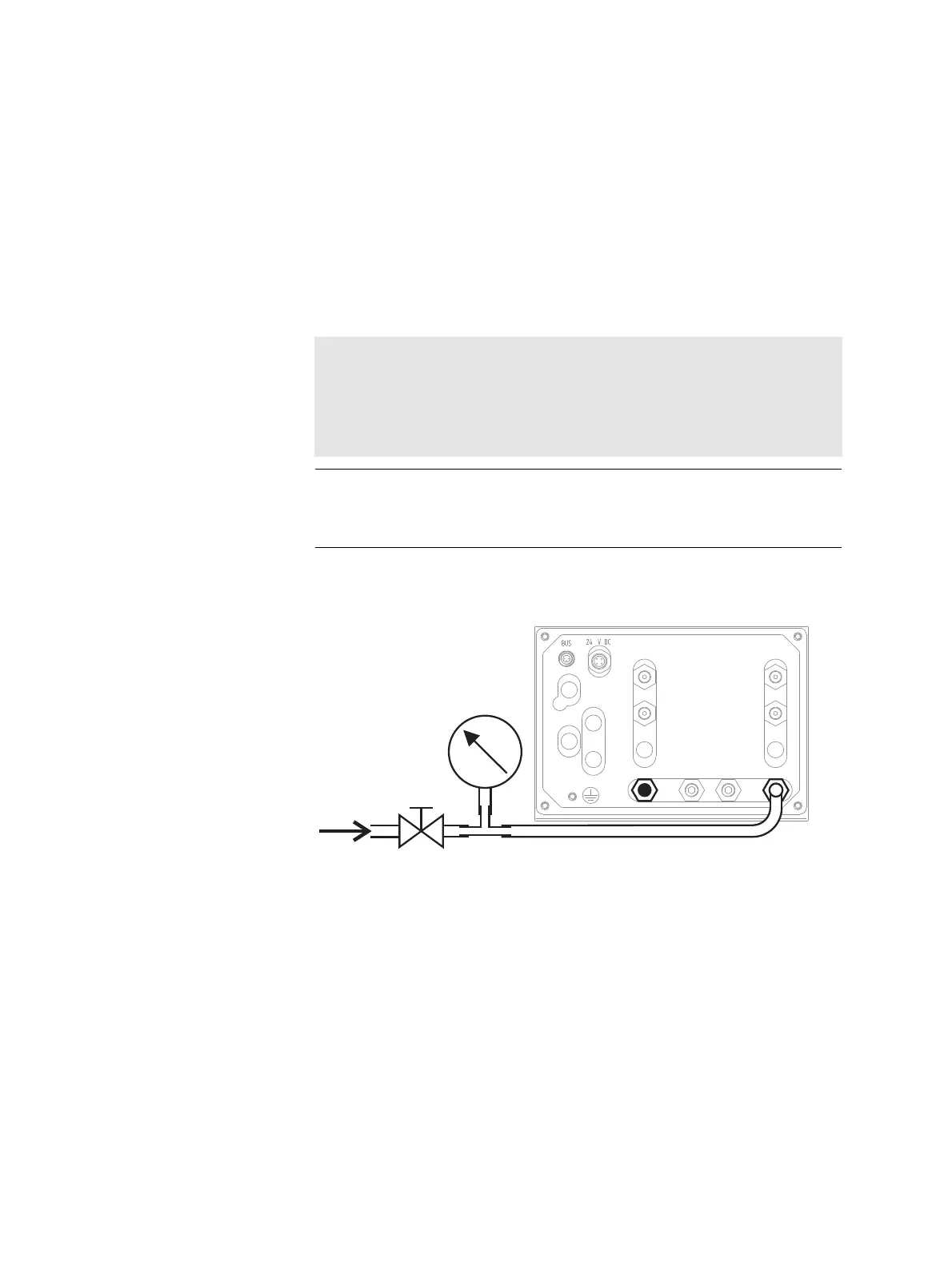

Requisite material

1 pressure gauge, 1 plastic tubing, (3 feet in length), 1 T-piece with shut-off

valve, air or nitrogen

CAUTION

If the seal integrity test is to be carried out with air and there is the pos-

sibility of a combustion gas being present in the gas paths or if a com-

bustion gas is to be introduced later, the gas paths should first be purged

with nitrogen. Otherwise seal integrity test can be performed with nitro-

gen.

NOTE

The following instructions apply to all gas paths in the gas analyzer, there-

fore to all sample gas paths and – in the Caldos25 and Uras26 analyzer mod-

ules – to the reference gas path.

Checking gas path seal integrity

Example: Sample gas path in Magnos27

1

2

3

4567

8

9

10

11

12

14

13

Luft / Air

50 hPa

1 Seal the outlet of the gas path to be tested (7 in the example) so it is

gas-tight.

2 Connect plastic tubing with the T-piece fitted with a shut-off valve to

the inlet of the gas path to be tested (4 in the example).

3 Connect the free end of the T-piece to the pressure gauge.

4 Blow air or nitrogen through the shut-off valve until the sample gas feed

path is under a positive pressure of p

e

≈ 50 hPa (= 50 mbar). Close the

shut-off valve. Maximum positive pressure p

e

= 150 hPa (= 150 mbar).

Limas11 IR, Limas21 UV, Limas21 HW with quartz sample cell: Gauge

pressure p

e

≈ 400 hPa (= 400 mbar), Maximum positive pressure

p

e

= 500 hPa (= 500 mbar).

5 The pressure should not change measurably in 3 minutes ≤ 3 hPa). A

sharp pressure drop is a sign of a leak in the gas path being tested.

Limas11 IR, Limas21 UV, Limas21 HW with quartz sample cell: Test dura-

tion 15 minutes.

6 Repeat steps 1 to 5 for all gas paths in the gas analyzer.

Loading...

Loading...