4 Repair

4.5.4. Replacement of spherical roller bearing, balancing device

3193HAC022033-001 Revision: K

© Copyright 2004-2011 ABB. All rights reserved.

5. Apply grease to the new sealing rings and o-

rings and fit one of each to the new sealing

spacers. Also, grease the sealing spacers.

Spare part no:s are specified in Required

equipment on page 316.

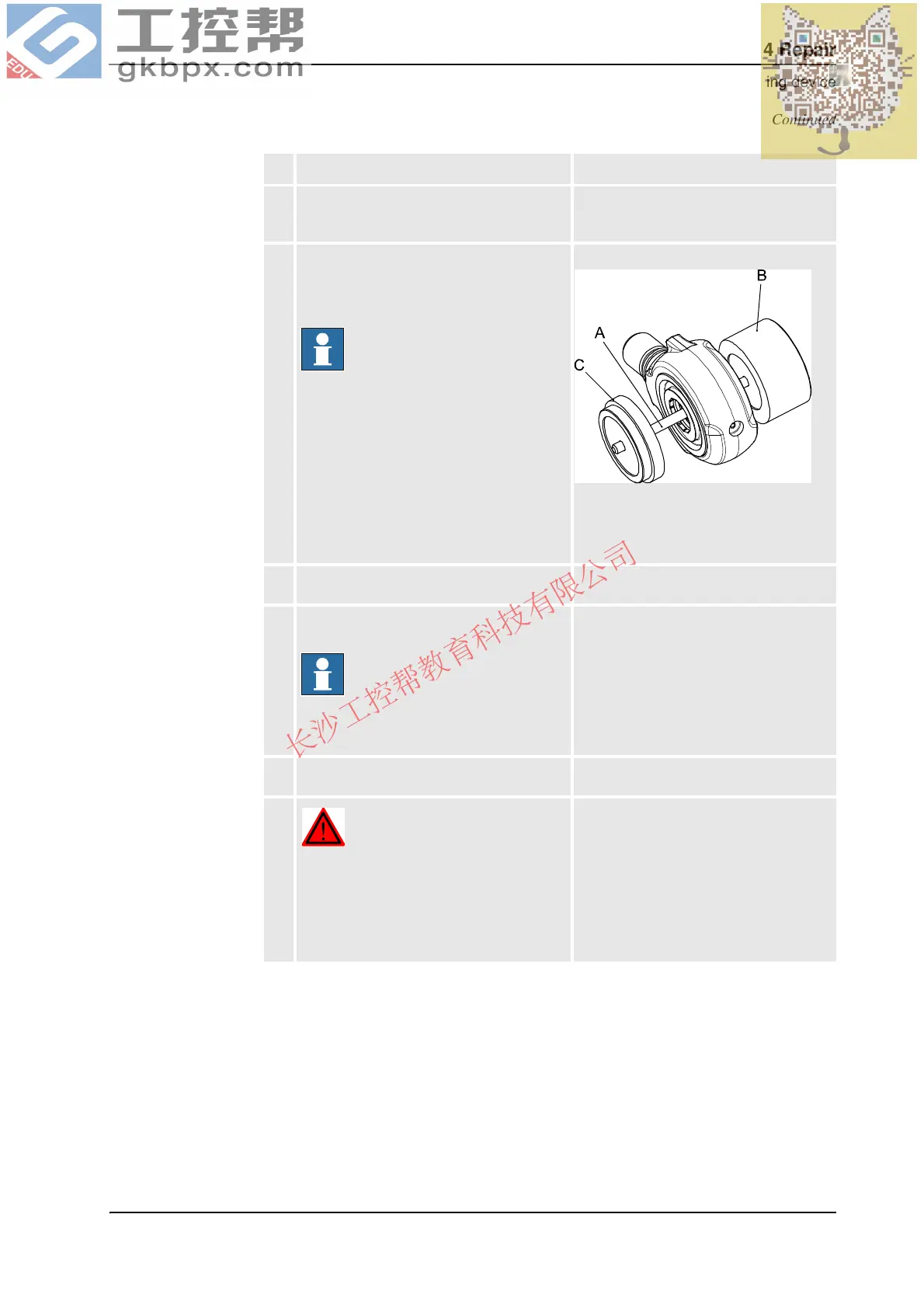

6. Press in the sealing spacers with the press

tools, as shown in the figure to the right.

Secure the press tool and dolly with nuts

and washers.

NOTE!

Fit the sealing spacers one at a time!

xx0500002258

A. Threaded bar 3HAC15945-1

B. Dolly 3HAC15948-1

C. Press tool 3HAC15846-1

7. Refit the balancing device to the robot. Detailed in section Refitting, balancing

device on page 312.

8. Lubricate the spherical roller bearing in the

ear.

NOTE!

The balancing device must be mounted on

the robot when lubrication is performed!

Detailed in section Lubrication of

spherical roller bearing, balancing device

on page 221

9. Make sure no incorrect leakage occurs. It

could indicate damaged o-rings.

Further information is available in section

Check for leakage on page 172.

10.

DANGER!

Make sure all safety requirements are met

when performing the first test run. These are

further detailed in the section DANGER -

First test run may cause injury or damage!

on page 47.

Action Note

Continued

Loading...

Loading...