2 Installation and commissioning

2.7.1. Robot cabling and connection points

1333HAC022033-001 Revision: K

© Copyright 2004-2011 ABB. All rights reserved.

2.7 Electrical connections

2.7.1. Robot cabling and connection points

Introduction

Connect the robot and controller to each other after securing them to the foundation. The lists

below specify which cables to use for each respective application.

Main cable categories

All cables between the robot and controller are divided into the following categories:

The cable categories are divided into sub-categories, specified below.

Robot cables

These cables are included in the standard delivery. They are completely pre-manufactured

and ready to plug in.

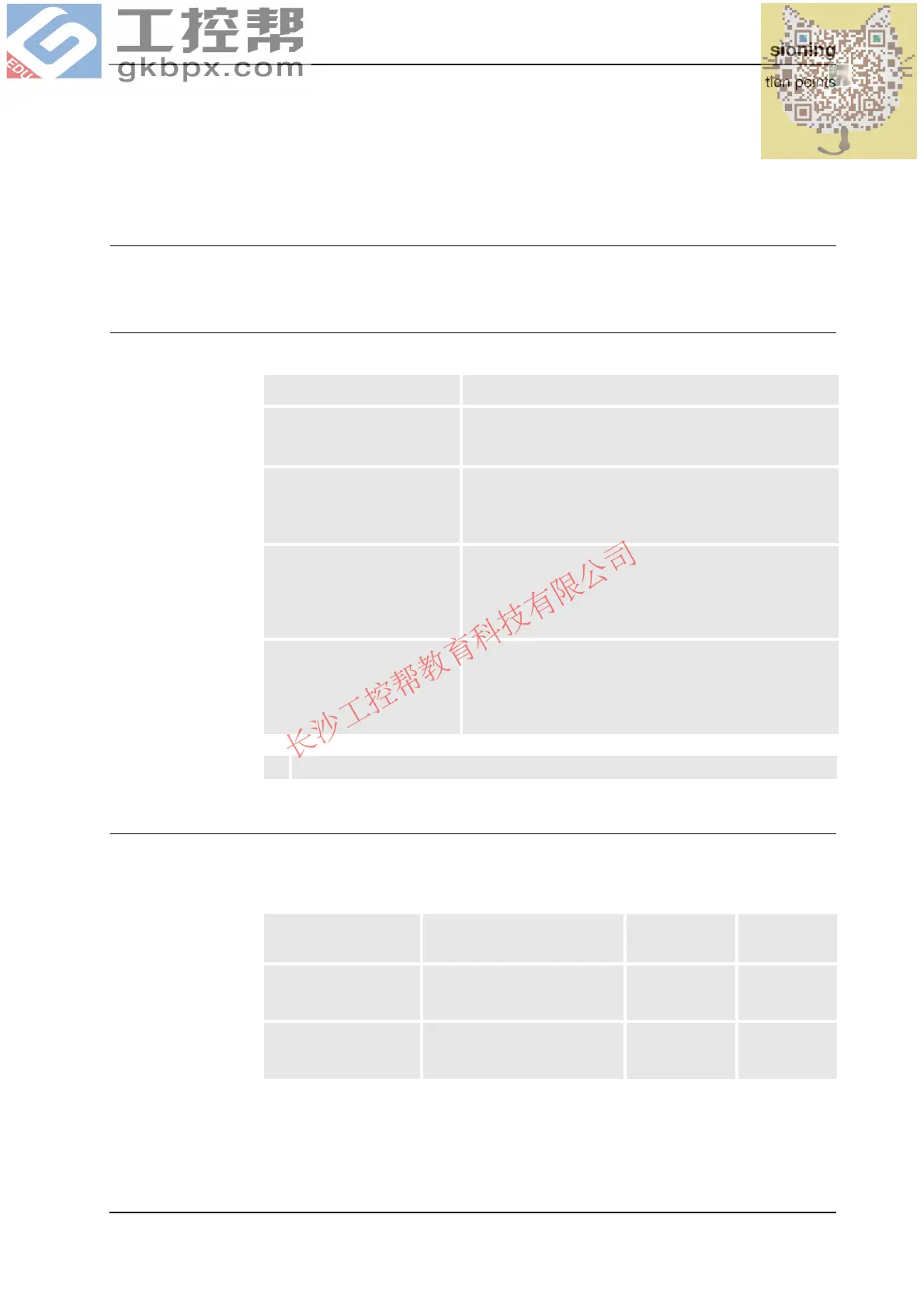

Cable category Description

Robot cables Handles power supply to and control of the robot's motors as

well as feedback from the serial measurement board.

Specified in the table Robot cables on page 133.

Position switch and fan cables

(option)

Handles supply to and feedback from any position switches

and cooling fans on the robot.

Specified in the table Position switch and fan cables, robot

base to controller (option) on page 134.

Customer cables (option) Handles communication with equipment fitted on the robot

by the customer, including databus communication, low

voltage signals and high voltage power supply + protective

ground.

See the product manual for the controller

1)

.

External axes cables (option) Handles power supply to and control of the external axes'

motors as well as feedback from the servo system.

See the Application manual - Additional axes and stand

alone controller (M2004)orApplication manual - External

axes (M2000)

1)

.

1)

Art. no. is specified in section References on page 10.

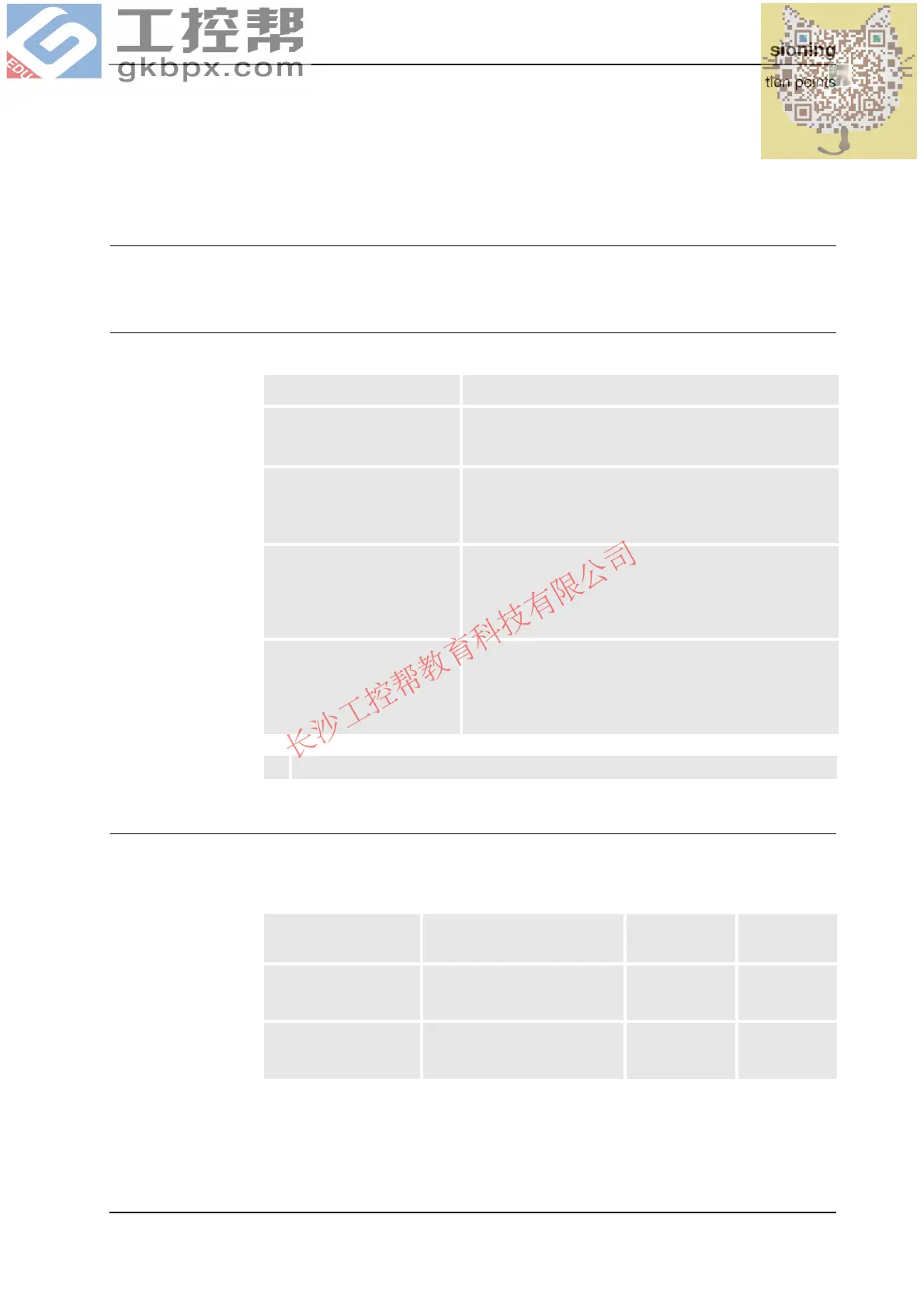

Cable sub-category Description

Connection

point, cabinet

Connection

point, robot

Robot cable, power Transfers drive power from the

drive units in the control cabinet

to the robot motors.

XS1 R1.MP

Robot cable, signals Transfers resolver data from

and power supply to the serial

measurement board.

XS2 R1.SMB

Continues on next page

Loading...

Loading...