Reflected Wave 2-127

Reflected Wave [Compensation]

The pulses from a Pulse Width Modulation (PWM) inverter using IGBTs

are very short in duration (50 nanoseconds to 1 millisecond). These short

pulse times combined with the fast rise times (50 to 400 nanoseconds) of

the IGBT, will result in excessive over-voltage transients at the motor.

Voltages in excess of twice the DC bus voltage,(650V DC nominal @ 480 V

input) result at the motor and can cause motor winding failure.

The patented reflected wave correction software in the PowerFlex 70 will

reduce these over-voltage transients from a VFD to the motor. The

correction software modifies the PWM modulator to prevent PWM pulses

less than a minimum time from being applied to the motor. The minimum

time between PWM pulses is 10 microseconds. The modifications to the

PWM modulator limit the over-voltage transient to 2.25 per unit volts

line-to-line peak at 600 feet of cable.

400 V Line + 10% High Line = 540V DC bus X 2.25 = 1200 V

480 V Line + 10% High Line = 715V DC bus X 2.25 = 1600 V

600 V Line + 10% High Line = 891V DC bus X 2.25 = 2000 V

(inverter duty grade motor insulation)

The software is standard and requires no special parameters or settings.

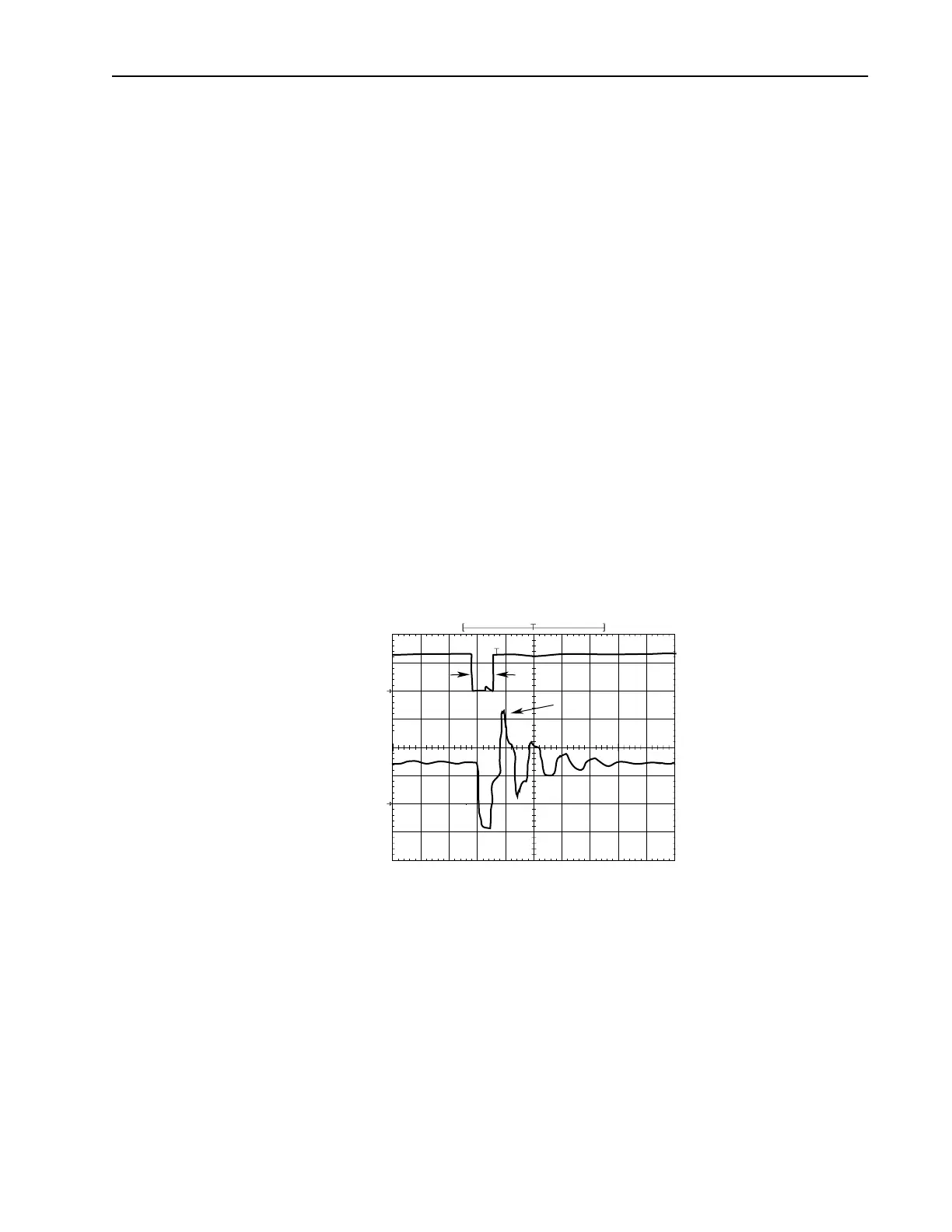

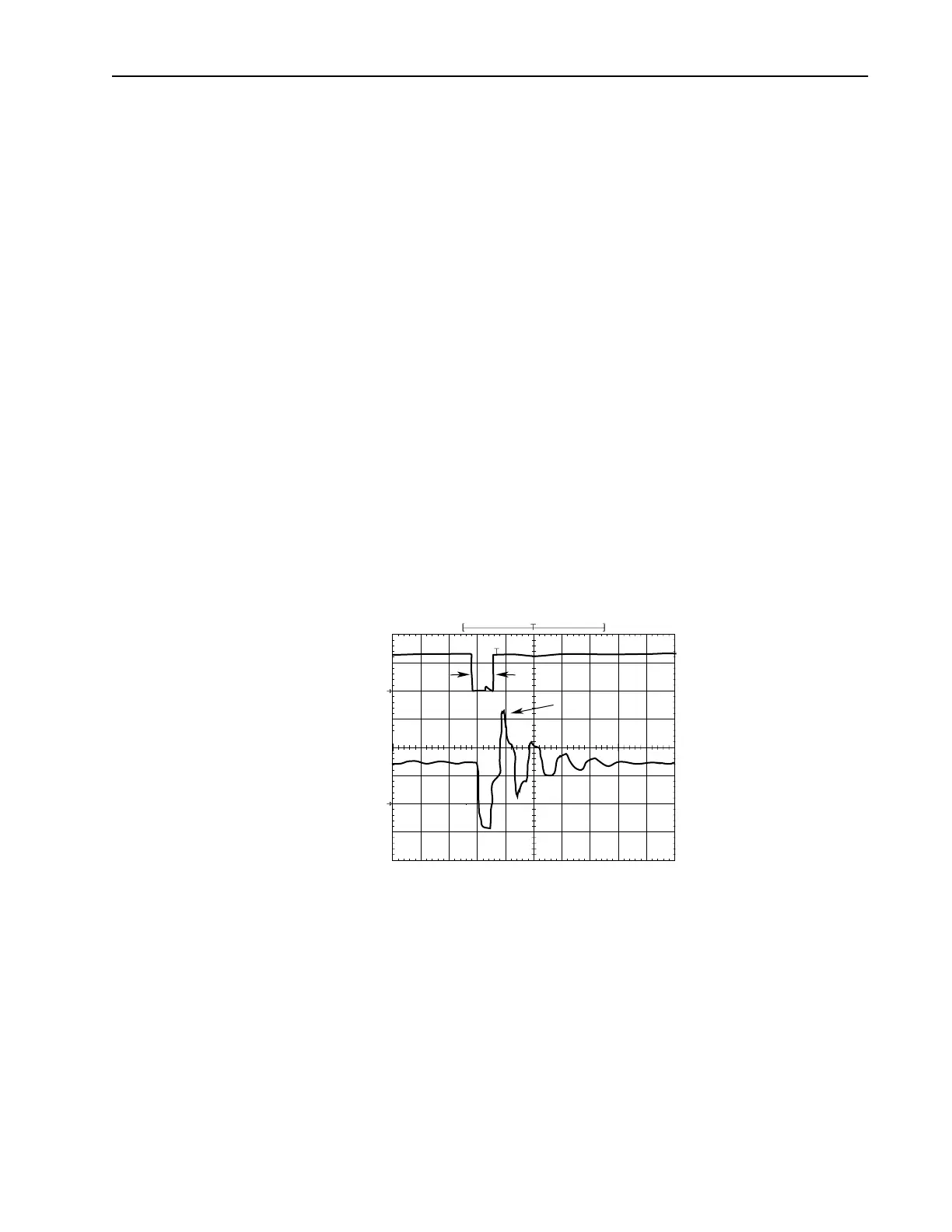

The above figure shows the inverter line-to-line output voltage (top trace)

and the motor line-to-line voltage (bottom trace) for a 10 HP, 460V AC

inverter, and an unloaded 10 HP AC induction motor at 60 Hz operation.

500 ft. of #12 AWG PVC cable connects the drive to the motor.

Initially, the cable is in a fully charged condition. A transient disturbance

occurs by discharging the cable for approximately 4ms. The propagation

delay between the inverter terminals and motor terminals is approximately

1ms. The small time between pulses of 4ms does not provide sufficient time

to allow the decay of the cable transient. Thus, the second pulse arrives at a

point in the motor terminal voltage's natural response and excites a motor

<T

α

1670 V

pk

5010152025

Time ( sec)

30 35 40 45 50

500

V/div

0

500

V/div

Inverter

Motor

0

Loading...

Loading...