Cable, Power 2-33

Cable, Power

A variety of cable types are acceptable for drive installations. For many

installations, unshielded cable is adequate, provided it can be separated

from sensitive circuits. As an approximate guide, allow a spacing of 0.3

meters (1 foot) for every 10 meters (32.8 feet) of length. In all cases, long

parallel runs must be avoided. Do not use cable with an insulation thickness

less than or equal to 15 mils (0.4 mm/0.015 in.).

Shielded/Armored

Shielded cable is recommended if sensitive circuits or devices are

connected or mounted to the machinery driven by the motor.

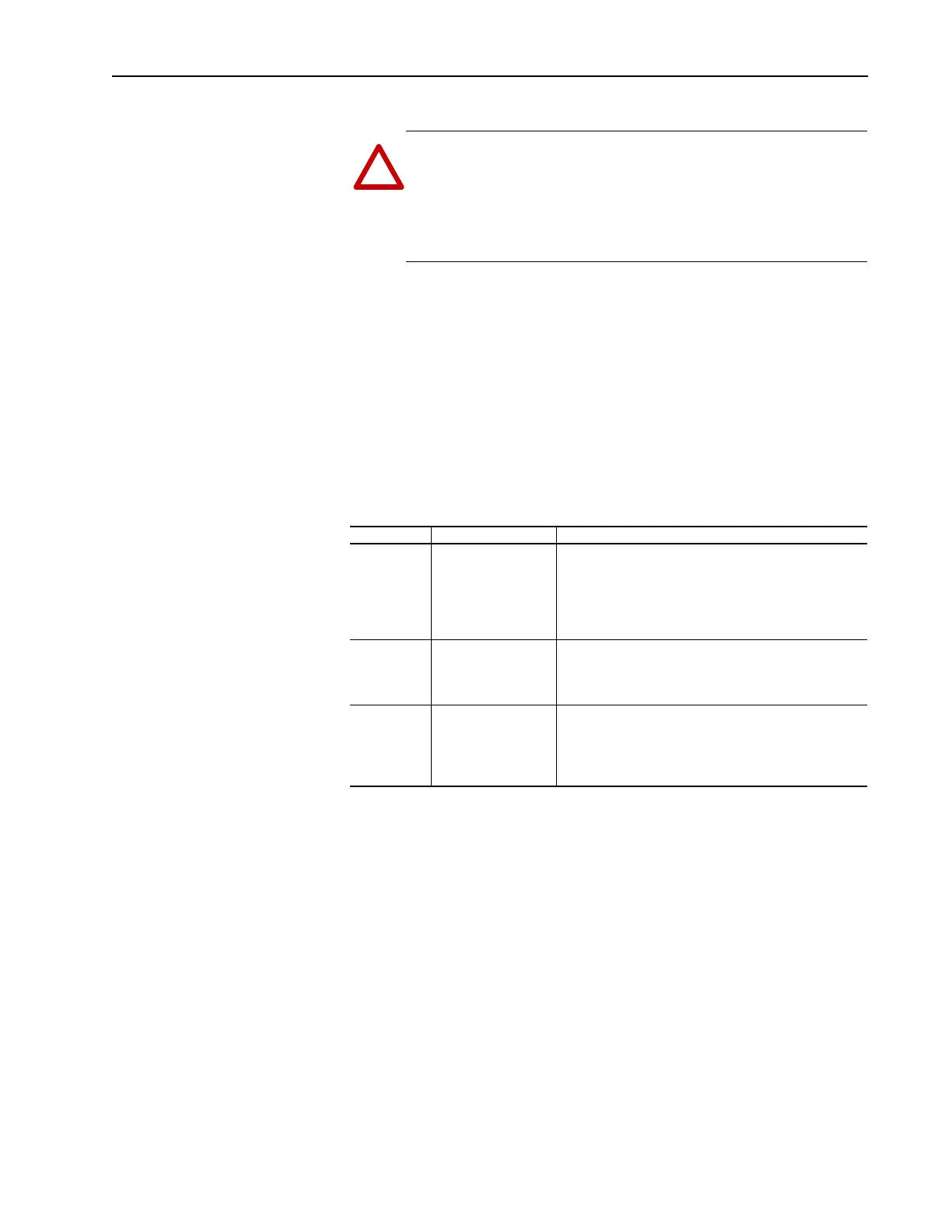

Figure 2.4 Recommended Power Wire

Based on field and internal testing, Rockwell Automation/Allen-Bradley

has determined conductors manufactured with Poly Vinyl Chloride (PVC)

wire insulation are subject to a variety of manufacturing inconsistencies

which can lead to premature insulation degradation when used with IGBT

drives that produce the reflected wave phenomena. Flame-retardant

heat-resistant thermoplastic insulation is the type of insulation listed in the

NEC code for the THHN wire designation. This type of insulation is

commonly referred to as PVC. In addition to manufacturing

inconsistencies, the physical properties of the cable can change due to

environment, installation and operation, which can also lead to premature

insulation degradation. The following is a summary of our findings:

!

ATTENTION: National Codes and standards (NEC, VDE, BSI

etc.) and local codes outline provisions for safely installing

electrical equipment. Installation must comply with specifications

regarding wire types, conductor sizes, branch circuit protection

and disconnect devices. Failure to do so may result in personal

injury and/or equipment damage.

Location Rating/Type Description

Standard

(Option 1)

600V, 90°C (194°F)

XHHW2/RHW-2

Anixter

B209500-B209507,

Belden 29501-29507,

or equivalent

• Four tinned copper conductors with XLP insulation.

• Copper braid/aluminum foil combination shield and

tinned copper drain wire.

• PVC jacket.

Standard

(Option 2)

Tray rated 600V, 90° C

(194° F) RHH/RHW-2

Anixter OLF-7xxxxx or

equivalent

• Three tinned copper conductors with XLPE insulation.

• 5 mil single helical copper tape (25% overlap min.) with

three bare copper grounds in contact with shield.

• PVC jacket.

Class I & II;

Division I & II

Tray rated 600V, 90° C

(194° F) RHH/RHW-2

Anixter 7V-7xxxx-3G or

equivalent

• Three bare copper conductors with XLPE insulation and

impervious corrugated continuously welded aluminum

armor.

• Black sunlight resistant PVC jacket overall.

• Three copper grounds on #10 AWG and smaller.

Loading...

Loading...