7.4 Gas connection

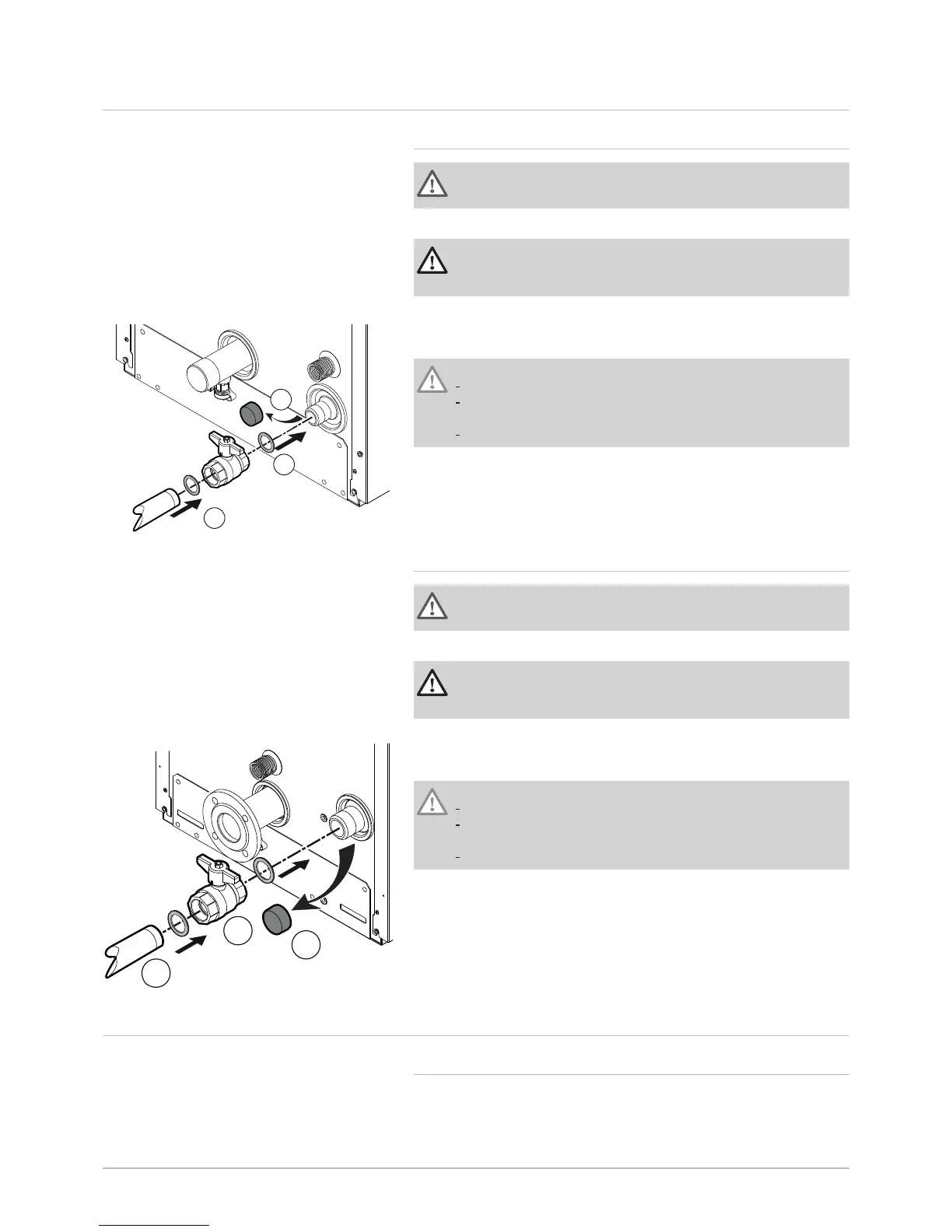

7.4.1 POWER HT+ 1.130 and POWER HT+ 1.150

Warning

Close the main gas valve before starting work on the gas pipes.

The gas pipes are not provided.

Danger

The diameters of the pipes must be defined in accordance with

the standards in force in your country.

1. Remove the anti-dust plug located on the boiler's gas inlet.

2. Fit a gas stop valve (not provided) on the boiler's gas inlet (G1”).

3. Connect the gas inlet pipe to the gas stop valve.

Caution

Ensure that there is no dust in the gas pipe.

Connect the gas pipe in accordance with prevailing standards

and regulations.

Check the leak-tightness using a leak detector spray.

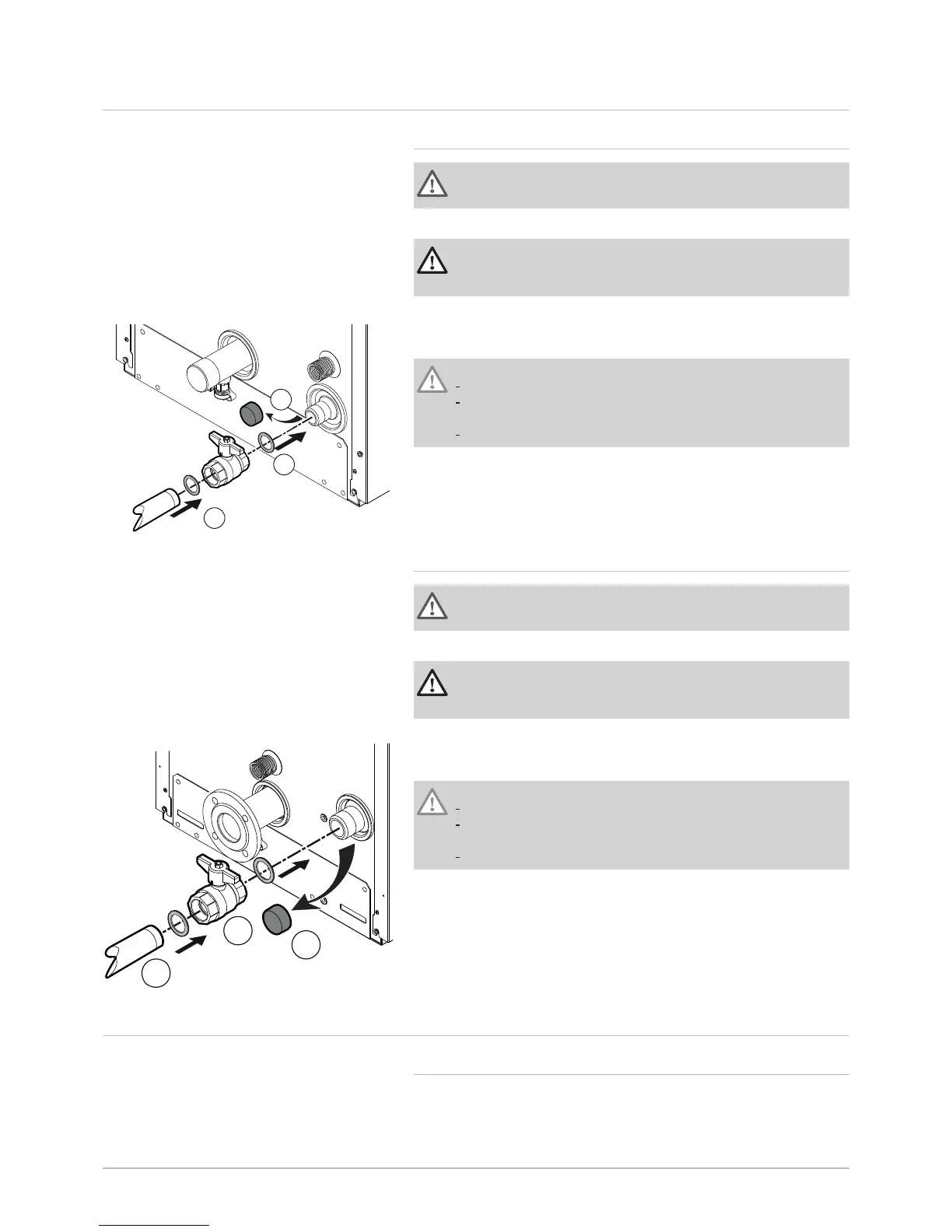

7.4.2 POWER HT+ 1.200 and POWER HT+ 1.250

Warning

Close the main gas valve before starting work on the gas pipes.

The gas pipes are not provided.

Danger

The diameters of the pipes must be defined in accordance with

the standards in force in your country.

1. Remove the anti-dust plug located on the boiler's gas inlet.

2. Fit a gas stop valve (not provided) on the boiler's gas inlet (G1”1/2).

3. Connect the gas inlet pipe to the gas stop valve:

Caution

Ensure that there is no dust in the gas pipe.

Connect the gas pipe in accordance with prevailing standards

and regulations.

Check the leak-tightness using a leak detector spray.

7.5

Air supply/flue gas outlet connections

7.5.1 Classification

The discharge and intake pipes must be certified for the appropriate

configuration and must meet the requirements of the prevailing installation

standards in the country.

Fig.70

Loading...

Loading...