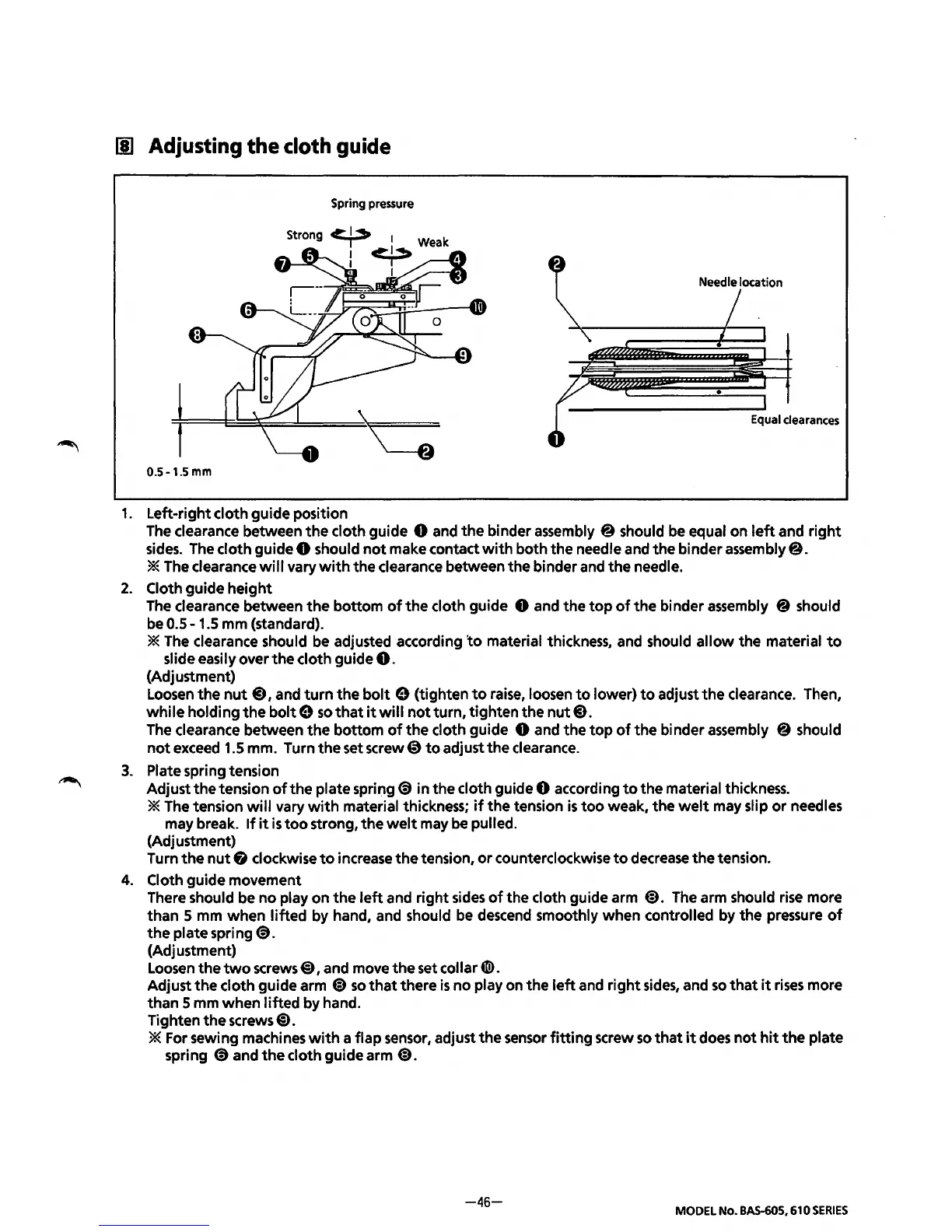

111

Adjusting

the

cloth

guide

Spring

pressure

Needle location

Equal

clearances

0.5-1.5

mm

1.

Left-right cloth guide position

The

clearance between

the

cloth guide 0 and

the

binder assembly @ should be equal on

left

and

right

sides.

The cloth guide 0 should

not

make contact

with

both the needle and

the

binder assembly@.

*

The clearance

will

vary

with

the

clearance between the binder and

the

needle.

2.

Cloth guide

height

The clearance between

the

bottom

of

the

cloth guide 0 and the

top

of

the

binder assembly @ should

be

0.5-

1.5 mm (standard).

*The

clearance should be adjusted according 'to material thickness, and should

allow

the material

to

slide easily over

the

cloth guide

0.

(Adjustment)

Loosen

the

nut

8 I and

turn

the

bolt

e (tighten

to

raise, loosen

to

lower)

to

adjust

the

clearance. Then,

while

holding

the

bolt

e

so

that

it

will

not

turn, tighten the

nut

8.

The clearance between

the

bottom

of

the

cloth guide 0 and

the

top

of

the

binder assembly @ should

not

exceed 1.5 mm. Turn

the

set

screw~

to

adjust

the

clearance.

3.

Plate spring tension

Adjustthe

tension

ofthe

plate spring

€)

in the cloth guide 0 according

to

the

material thickness.

*The

tension

will

vary

with

material thickness;

if

the

tension

is

too

weak, the

welt

may slip

or

needles

may break.

If

it

is

too

strong,

the

welt

may be pulled.

(Adjustment)

Turn

the

nut

8 clockwise

to

increase

the

tension,

or

counterclockwise

to

decrease

the

tension.

4.

Cloth guide movement

There

should be no play on

the

left

and

right

sides

of

the cloth guide arm

@).

The arm should rise more

than

5 mm

when

lifted

by hand, and should be descend smoothly when controlled by

the

pressure

of

the

plate spring

€).

(Adjustment)

Loosen

the

two

screws@), and move

the

set collar

4ID.

Adjust

the

cloth guide arm

@)

so

that

there

is

no

play on the

left

and

right

sides,

and

so

that

it

rises

more

than

5 mm

when

lifted

by hand.

Tighten

the

screws@).

*For

sewing machines

with

a flap sensor, adjust

the

sensor

fitting

screw

so

that

it

does

not

hit

the

plate

spring

€)

and

the

cloth guide arm

@).

-46-

MODEL

No.

BAS-605,

610

SERIES