II-1

CHAPTER II GENERAL MECHANISMS

2.1 MAIN MECHANISM

2.1.1 Print Mechanism

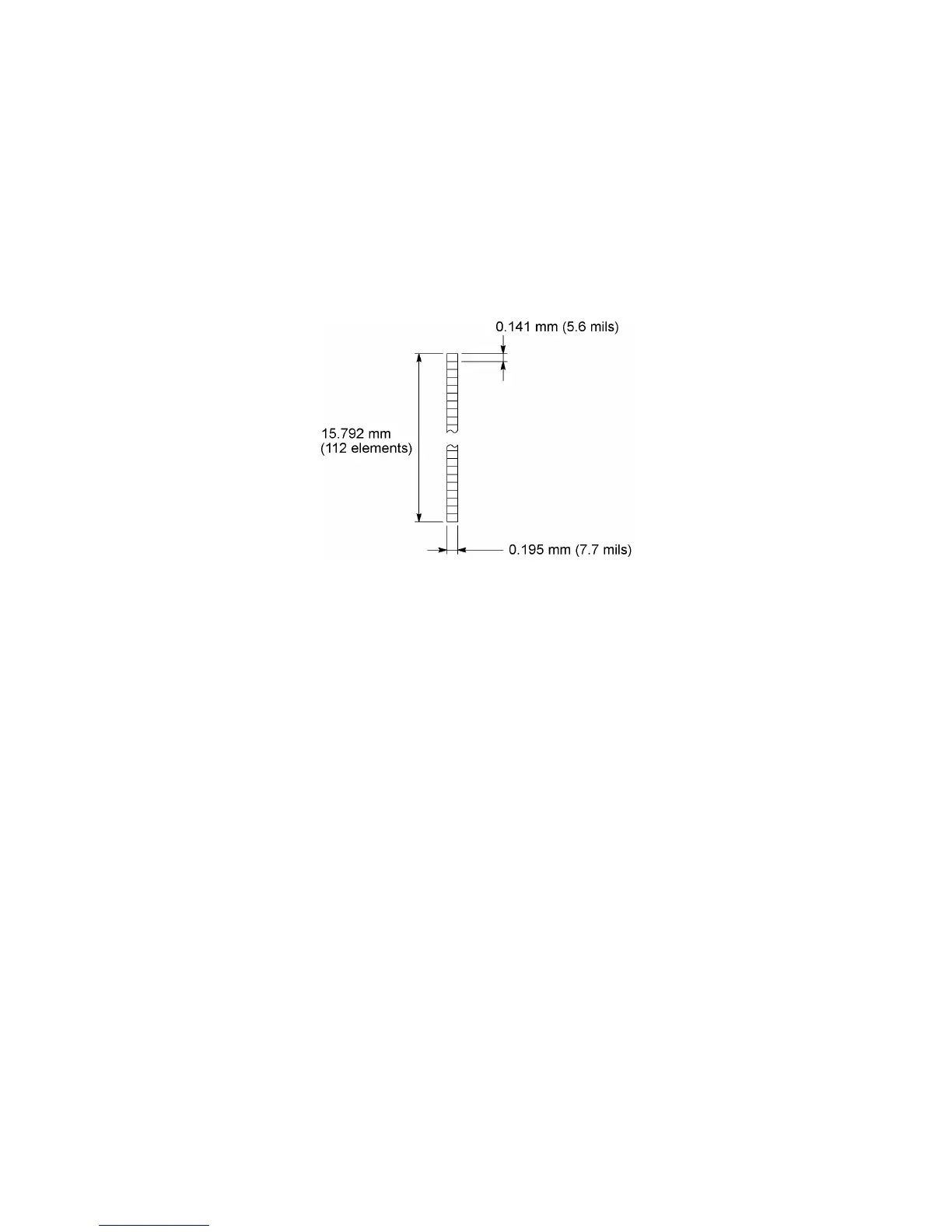

(1) Structure of Thermal Head

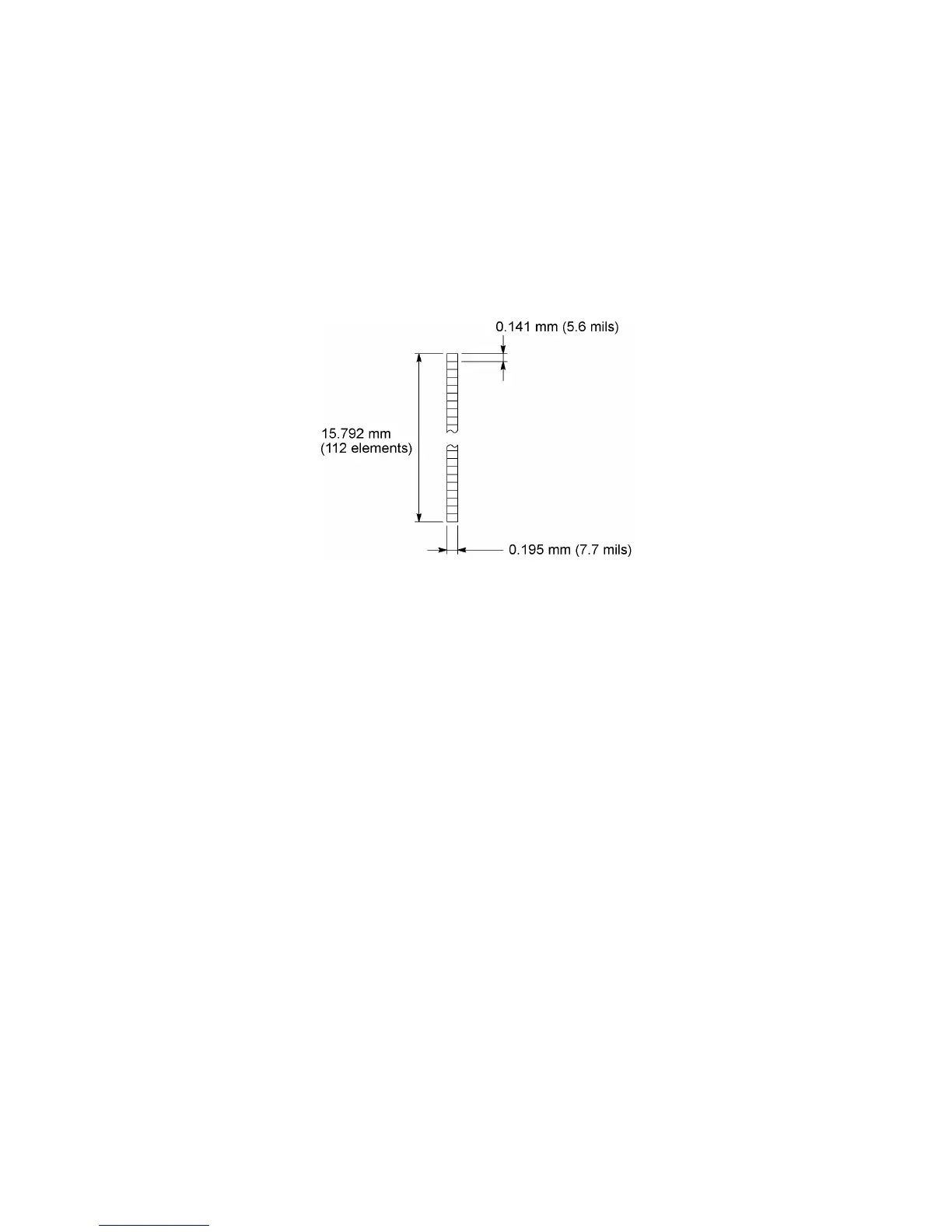

This machine uses thermal transfer printing. The thermal print head has a heat generator

consisting of 112 heating elements which are vertically aligned as shown in Fig. 2.1-1.

Each heating element is 0.195 mm wide by 0.141 mm high.

Fig. 2.1-1 Heat Generator of Thermal Head

(2) Printing Process

When the cylindrical rubber platen is pressed against the thermal print head with the tape*

and ink ribbon** sandwiched inbetween, the CPU applies electric power to the selected ones

of those 112 heating elements.

* Laminate tape when using laminated tape cassettes.

Non-laminated tape when using non-laminated tape cassettes.

Instant lettering tape when using instant lettering tape cassettes.

Non-laminated thermal film tape when using non-laminated thermal film tape cassettes.

Iron-on transfer tape when using iron-on transfer tape cassettes.

Cloth tape when using cloth tape cassettes.

** When using non-laminated thermal film tape cassettes or stamp tape cassettes, no ink

ribbon is sandwiched.

[For tape cassettes except non-laminated thermal film tape cassettes and stamp tape

cassettes]

If the selected heating element(s) generates heat, the ink on the sandwiched ribbon will be

melted and transferred to the tape, producing a dot(s) on the tape. The ink ribbon and the

tape are advanced and then the next heating cycle is repeated, thus forming a character on

the tape.

[For non-laminated thermal film tape cassettes]

If the selected heating element(s) generates heat, the thermal film tape develops itself to

produce a dot on the tape. The tape is advanced and the next heating cycle is repeated,

thus forming a character on the tape.

Loading...

Loading...