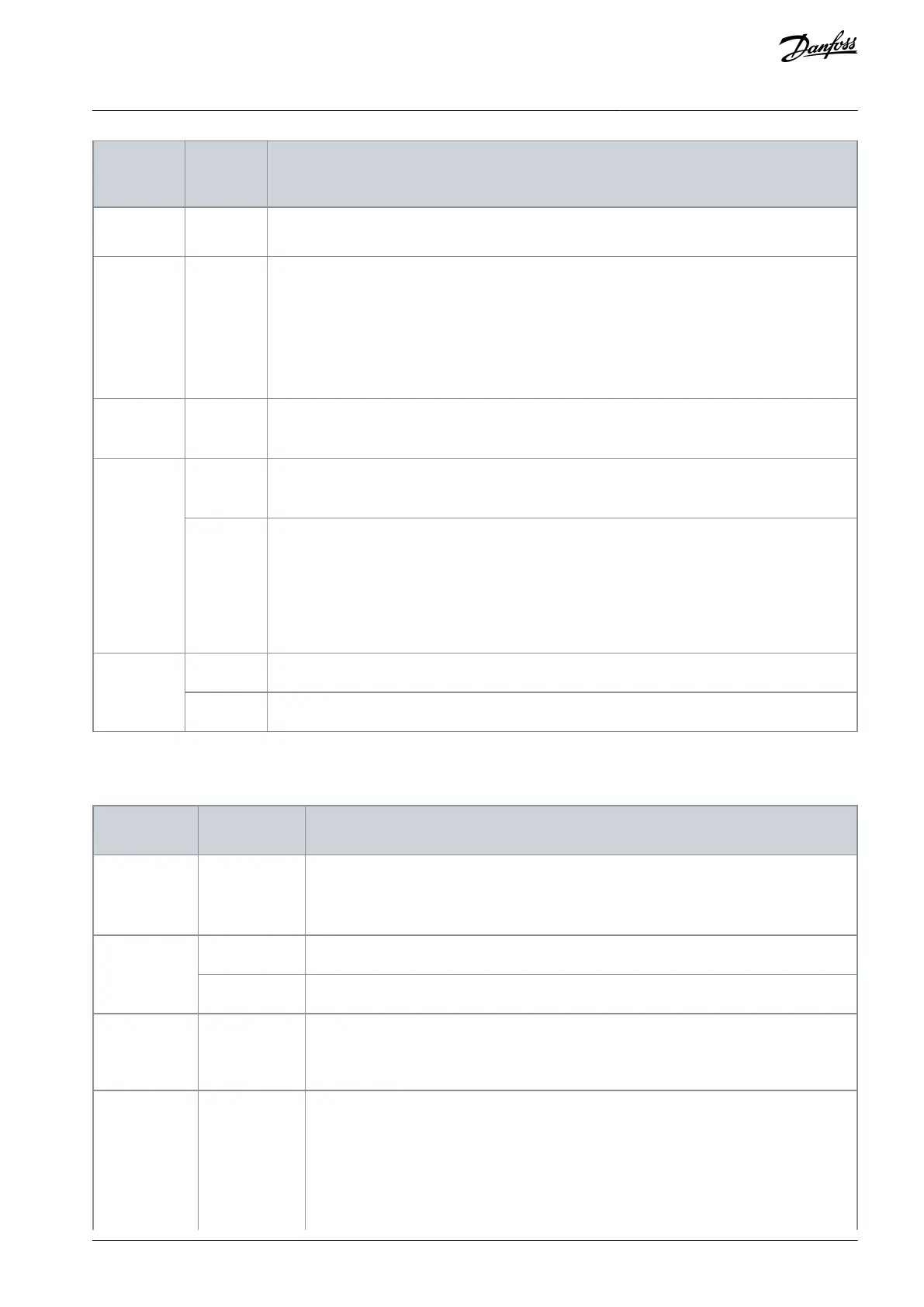

Check the condition of the ventilation and air ducts.

Record the environment parameters daily, and note if there are abnormal conditions.

Check that the drive input voltage is correct.

Check that the drive operating parameters are normal.

Check the drive for warnings/faults.

Check the indicator lights of the drive.

Check that the temperature of the transformer, shown on HMI, is below 90°C.

Check that there is no abnormal sound, vibration, fire, or smell.

Check that there is no abnormal vibration or sound.

Check that there are no cooling fan overtemperature or cooling fan power supply drop alarms.

Check that the air filters are not blocked.

Check that there is no air pressure alarm.

Clean the filters at least once a week. If the dust is heavy, the cleaning interval must be shorter.

To remove dust, gently tap the filters or blow slightly with compressed air outside the electrical

room.

To remove caked on dirt, rinse the filters with water and a gentle detergent. Dry the filters before

installing back on the drive.

If necessary, replace the filters with new ones.

Check the drive room daily. Remove any foreign items.

Clean the drive room once a week. Use a vacuum cleaner or mop to clean any dust or ash.

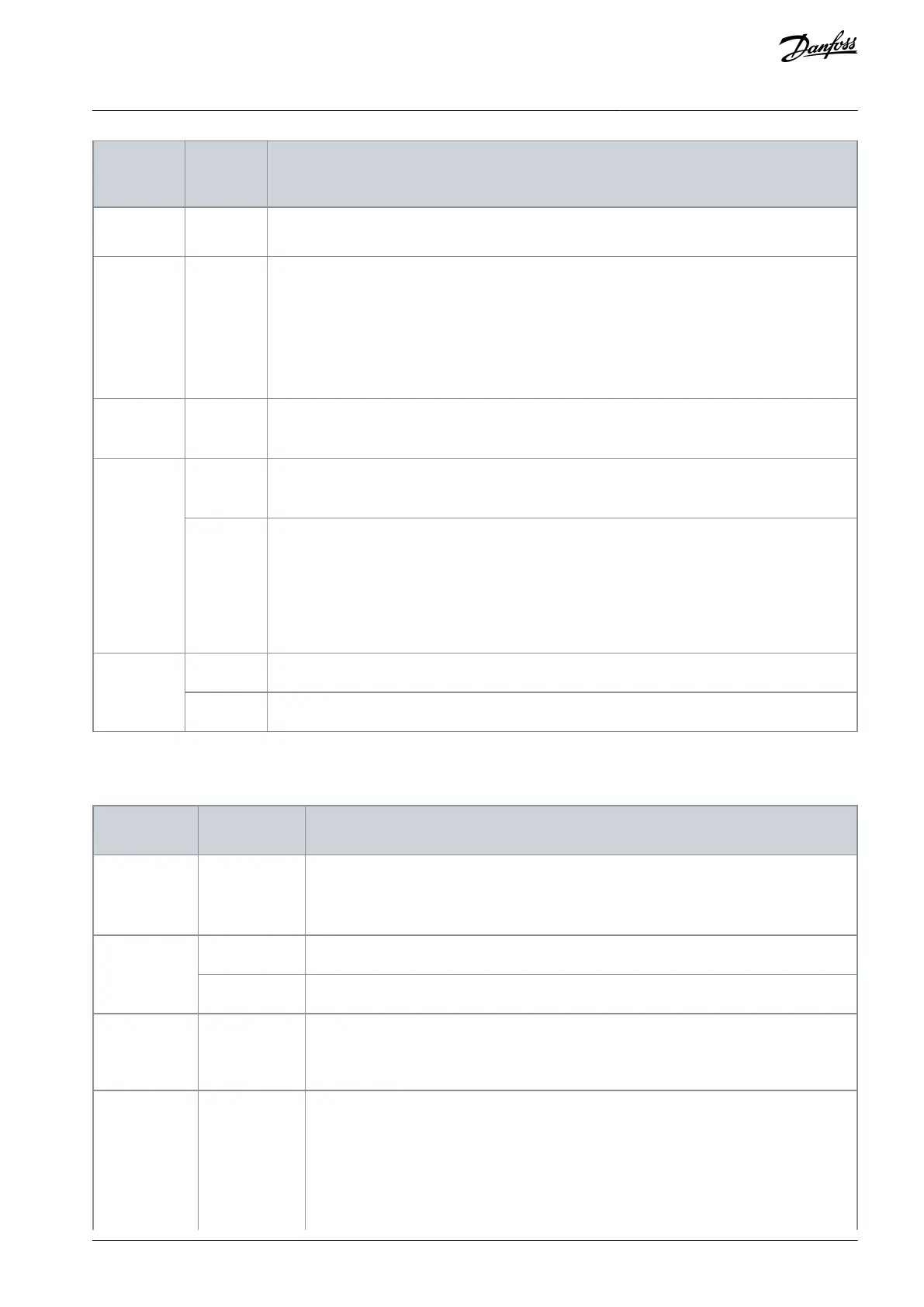

9.3.2 Yearly Maintenance

Table 11: Yearly Maintenance Tasks

Check the tightening torques of the terminals.

Check that the insulation layer of cables is not damaged.

Check the grounding.

Measure the insulation resistance between primary/secondary to ground.

Perform dielectric withstand tests between primary/secondary to ground.

Clean inside the drive cabinets with a vacuum cleaner.

Clean the dust on the surface of components, and clean the dust in the heat sinks of power

cells.

Use a multimeter to check that the output voltage of power supply in control cabinet is

26±0.5 V DC.

Check that the output voltage of the UPS is 25±0.5 V DC.

Check that the relay works normally and there is no abnormal sound.

Check that the indicators work normally.

Check that the electromagnetic interlocks work normally.

AQ363633621020en-000201 / 172F3117 | 81Danfoss A/S © 2021.06

Maintenance

VACON® 1000

Operating Guide

Loading...

Loading...