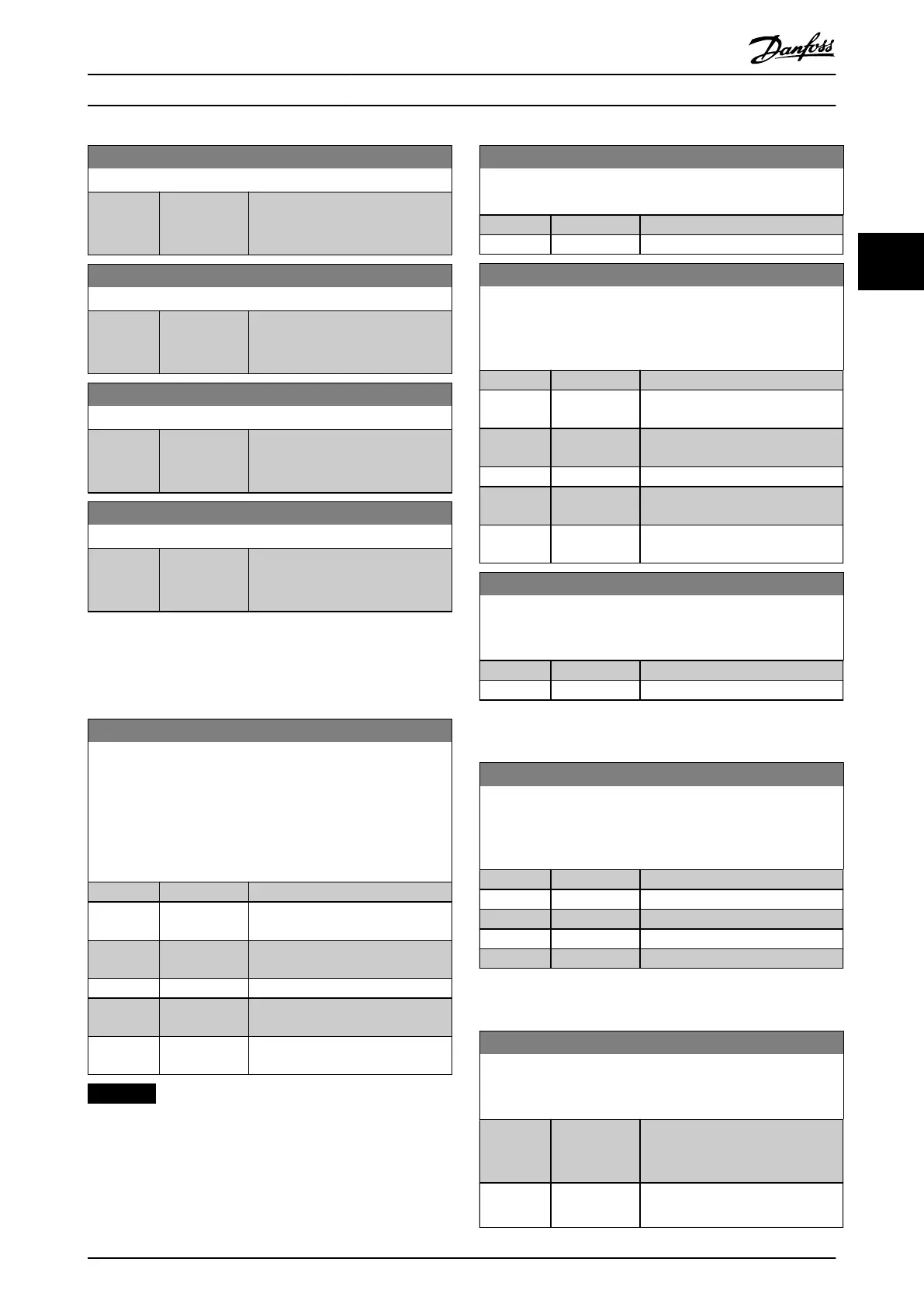

16-93 Warning Word 2

Range: Function:

0* [0 -

0xFFFFFFFFUL

]

View the warning word 2 sent via

the serial communication port in

hex code.

16-94 Ext. Status Word

Range: Function:

0* [0 -

0xFFFFFFFFUL

]

Shows the extended status word

sent via the serial communication

port in hex code.

16-95 Ext. Status Word 2

Range: Function:

0* [0 -

0xFFFFFFFFUL

]

Shows the extended status word 2

sent via the serial communication

port in hex code.

16-97 Alarm Word 3

Range: Function:

0* [0 -

0xFFFFFFFFUL

]

View the alarm word 3 sent via the

serial communication port in hex

code.

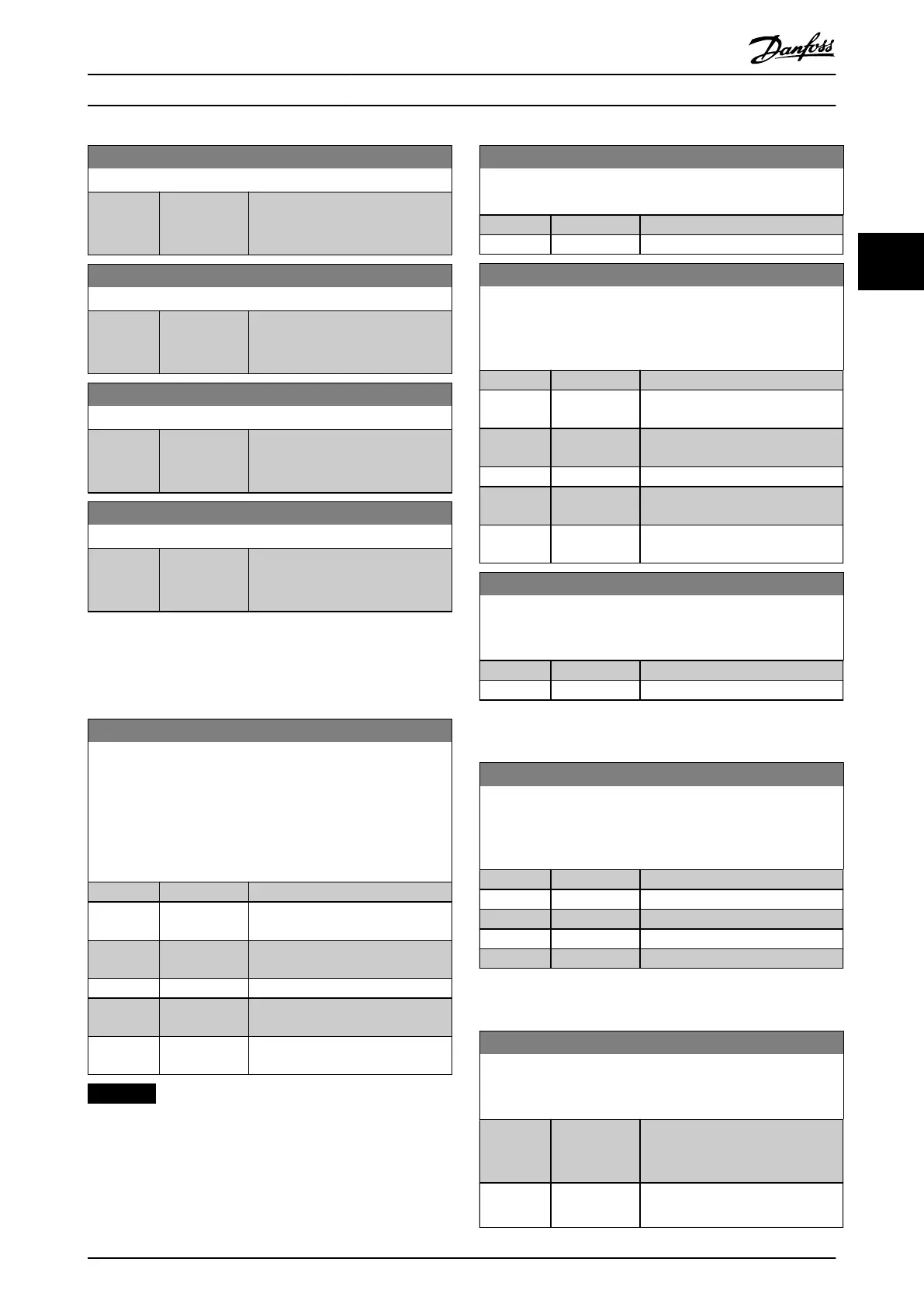

3.13 Main Menu - Drive Closed Loop -

Group 20

3.13.1 20-0* Feedback

20-00 Feedback 1 Source

Up to 3 dierent feedback signals can be used to provide the

feedback signal for the frequency converter’s PID controller.

This parameter denes which input is used as the source of the

rst feedback signal.

Analog input X30/11 and analog input X30/12 refer to inputs on

the optional General Purpose I/O board.

Option: Function:

[0] * No function

[1] Analog Input

53

[2] Analog Input

54

[3] Pulse input 29

[100] Bus Feedback

1

[101] Bus Feedback

2

NOTICE

If feedback is not used, set its source to [0] No Function.

Parameter 20-20 Feedback Function determines how the

PID controller uses the 3 possible feedbacks.

20-01 Feedback 1 Conversion

This parameter allows a conversion to be applied to feedback.

Option: Function:

[0] * Linear

[1] Square root

20-03 Feedback 2 Source

The eective feedback signal is made up of up to 3 dierent

input signals. Select which drive input should be treated as the

source of the second of these signals.

Option: Function:

[0] * No function

[1] Analog Input

53

[2] Analog Input

54

[3] Pulse input 29

[100] Bus Feedback

1

[101] Bus Feedback

2

20-04 Feedback 2 Conversion

Select a conversion for the feedback 2 signal. Select Linear to

leave the feedback signal unchanged.

Option: Function:

[0] * Linear

[1] Square root

3.13.2 20-2* Feedback/Setpoint

20-20 Feedback Function

Select how the feedback should be calculated. The feedback can

be either a single feedback source or a combination of several

feedbacks.

Option: Function:

[0] Sum

[1] Dierence

[2] Average

[3] * Minimum

[4] Maximum

3.13.3 20-8* PI Basic Settings

20-81 PI Normal/ Inverse Control

Select either [0] Normal or [1] Inverse to control the output speed

when the process error is positive.

Option: Function:

[0] * Normal Set the process control to increase

the output speed when the process

error is positive.

[1] Inverse Reduce the output speed when the

process error is positive.

Parameters Programming Guide

MG18P202 Danfoss A/S © 06/2019 All rights reserved. 63

3 3

Loading...

Loading...