88 Chapter 7 Maintenance

EV2000 Series Universal Variable Speed Drive User Manual

Chapter 7 Maintenance

Many factors such as ambient temperature, humidity, dust, vibration, internal component aging, wear and tear will give

rise to the occurrence of potential faults. Therefore, it is necessary to conduct routine maintenance to the drives.

Notes:

As safety precautions, before carrying out check and maintenance of the drive, please ensure that :

The drive has been switched off;

The charging LED lamp inside the drive is off.

Use a volt-meter to test the voltage between terminals (+) and (-) and the voltage should be below 36V.

7.1 Daily Maintenance

The drive must be operated in the environment specified in the Section 2.1. Besides, some unexpected accidents may

occur during operation. You should maintain the drive conditions according to the table below, record the operation data,

and find out problem in the early stage.

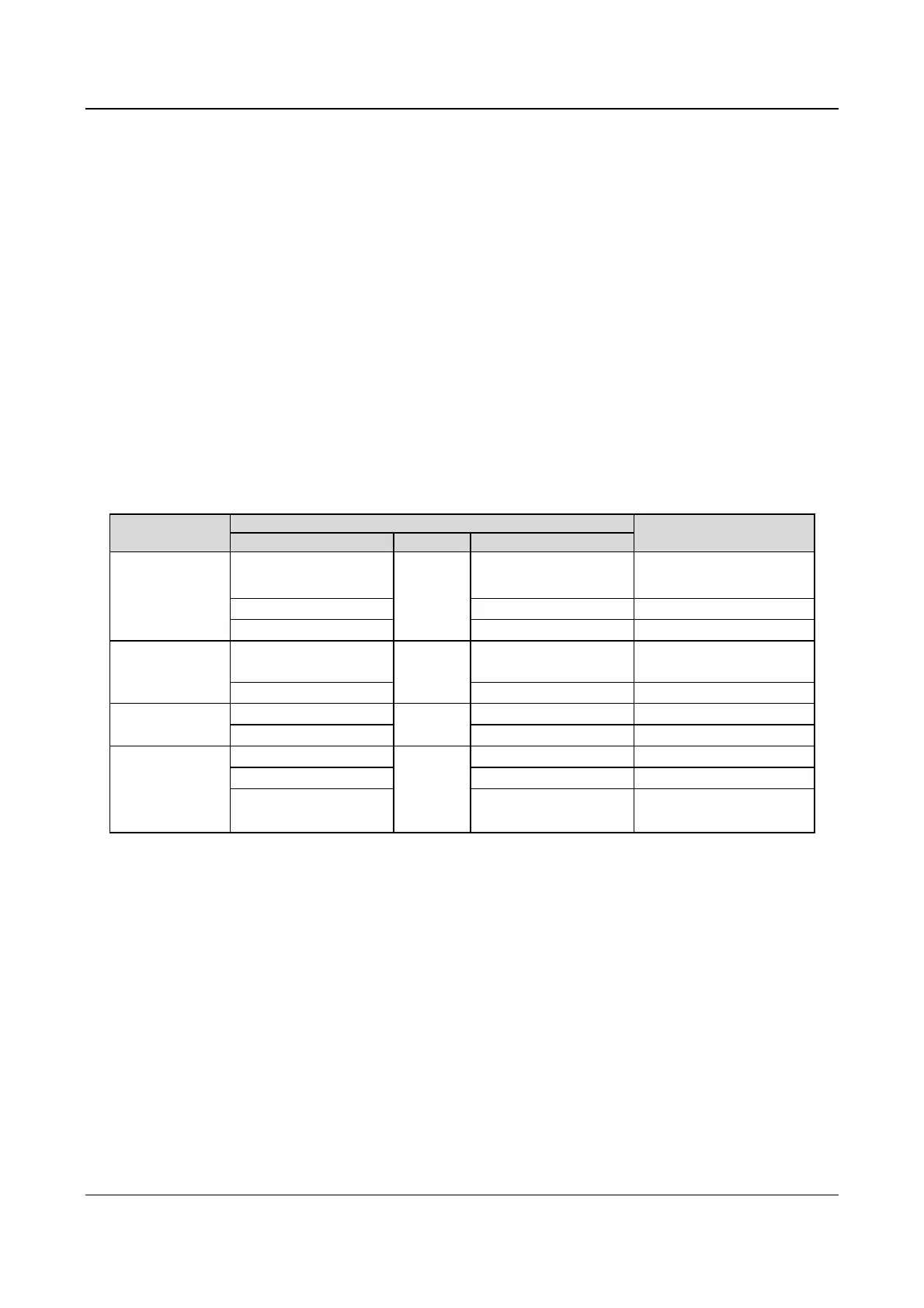

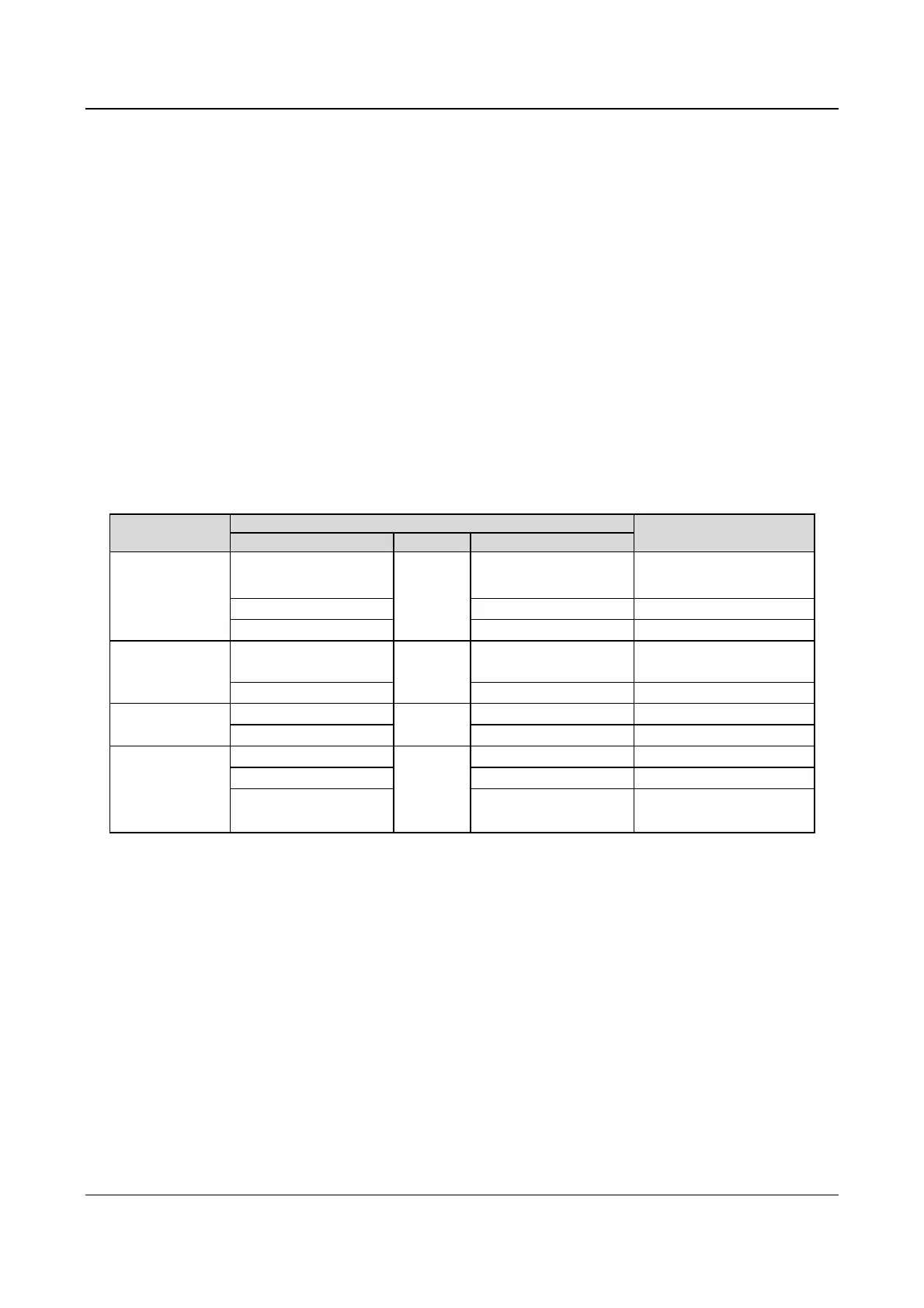

Table 7-1 Daily checking items

Items

Instructions

Criterion

Items Cycle Checking methods

Operating

environment

Temperature and

humidity

Any time

Thermometer and

hygrometer

-10

℃~+40℃,

derating at 40

℃~50℃

Dust and water dripping Visual inspection No water dripping

Gas Visual inspection No strange smell

Drive

Vibration and heating

Any time

Touch the case

Stable vibration and proper

temperature

Noise Listen No abnormal sound

Motor

Heating

Any time

Touch by hand No overheat

Noise Listen Low and regular noise

Operating status

parameters

Output current

Any time

Current meter Within rated range

Output voltage Volt-meter Within rated range

Internal temperature Thermometer

Temperature rise is smaller

than 35℃

7.2 Periodical Maintenance

Customer should check the drive every 3 months or 6

months according to the actual environment.

Notes:

1. Only trained personnel can dismantle the drive to replace

or repair components;

2. Don't leave metal parts like screws or pads inside the

drive; otherwise the equipment may be damaged.

General Inspection:

1. Check whether the screws of control terminals are

loose. If so, tighten them with a screwdriver;

2. Check whether the main circuit terminals are properly

connected; whether the mains cables are over heated;

3. Check whether the power cables and control cables

are damaged, check especially for any wear on the

cable tube;

4. Check whether the insulating tapes around the cable

lugs are stripped;

5. Clean the dust on PCBs and air ducts with a vacuum

cleaner;

6. For drives that have been stored for a long time, it

must be powered on every 2 years. When supplying AC

power to the drive, use a voltage regulator to raise the

input voltage to rated input voltage gradually. The drive

should be powered for 5 hours without load.

7. Before performing insulation tests, all main circuit

input/output terminals should be short-circuited with

conductors. Then proceed insulation test to the ground.

Insulation test of single main circuit terminal to ground is

Loading...

Loading...