Trouble shooting 64 EA4. 2

OUTDOOR UNIT Error Method:

High Pressure Protection 1

Indicate or Display:

Detective Actuators:

Detective details:

High pressure switch 1

"Protection stop by "high pressure switch 1 operated during compressor 1

operation"" generated 3 times within 60 minutes

Indoor Unit : Operation LED 9 times Flash, Timer LED 15 Times Flash,

Filter LED Continuous Flash.

Outdoor Unit : E. A 4. 2

Error Code : 9U / A 4

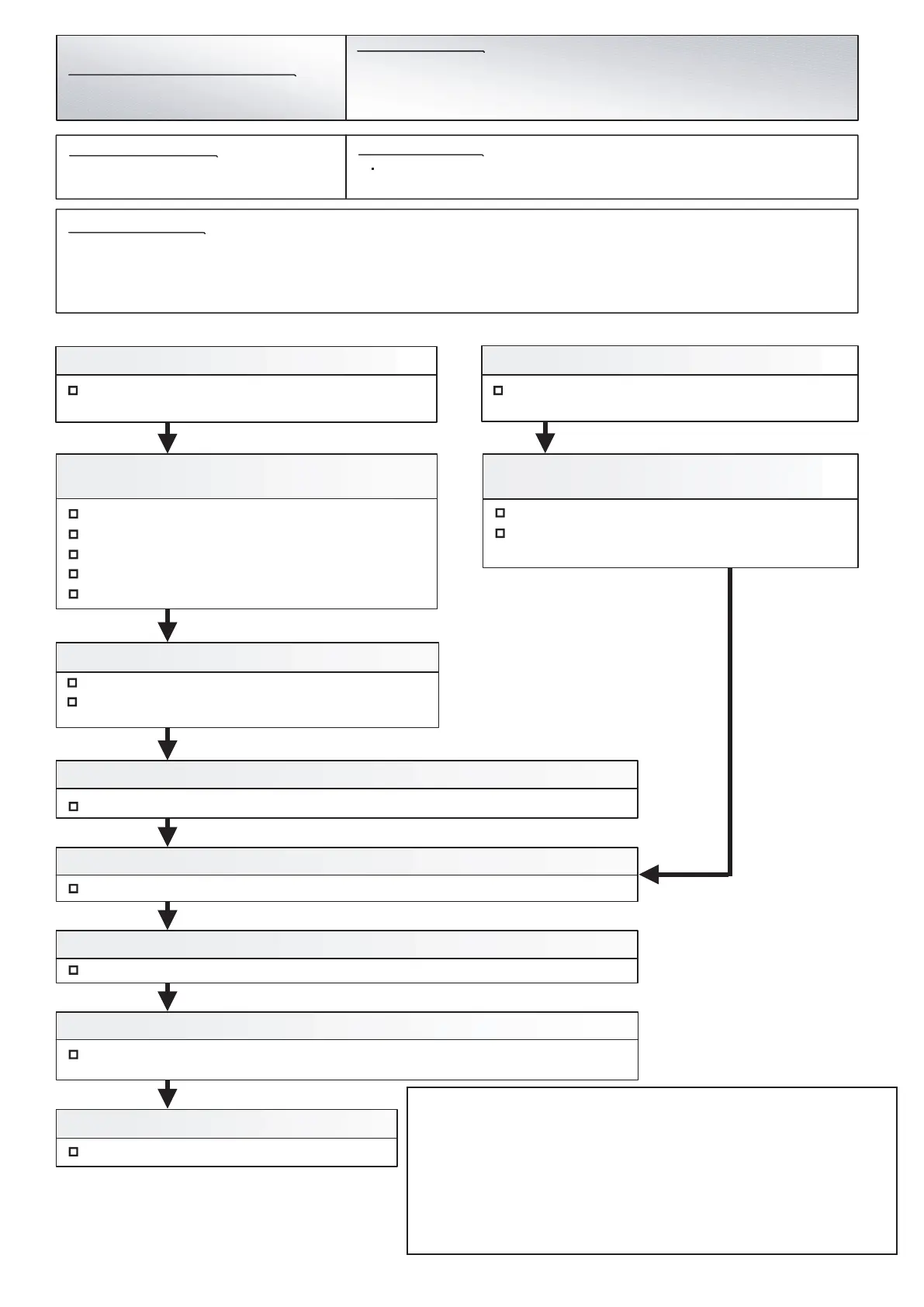

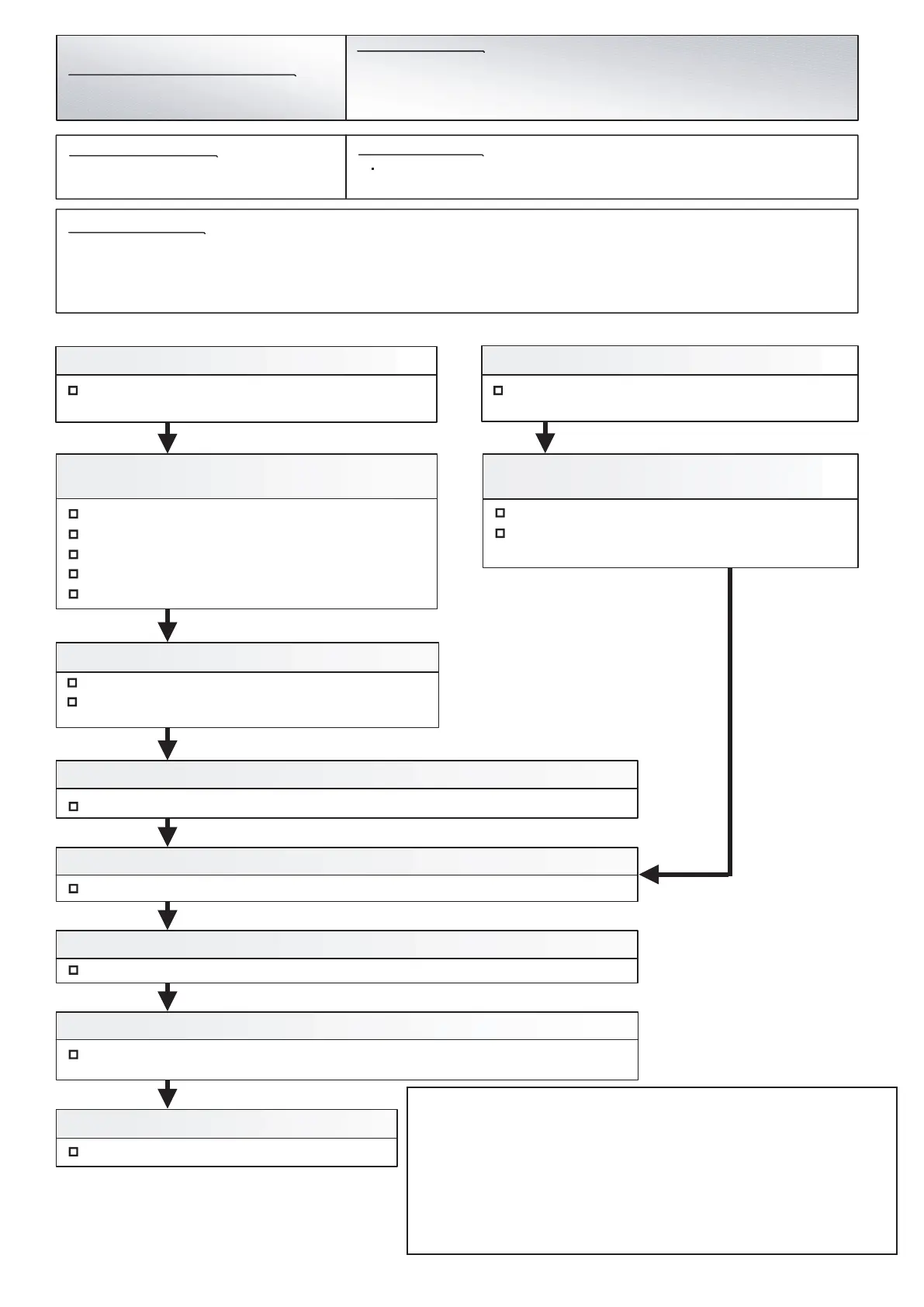

Forecast of Cause :

1. 3-way valve not opened

2. Outdoor unit fan operation defective, foreign matter at heat exchanger, excessive ambient

temperature rise 3. Check valve clogge 4. EEV defective, strainer clogged

5. Solenoid valve defective 6. 4-way valve (including a coil) defective

7. High pressure switch 1 defective 8. Refrigerant overcharged

EEV operation check

Check of strainers before and after EEV

Refer to "Service Parts Information 14".

Check Point 4 : Check the EEV, strainer (indoor unit)

No foreign matter in air passage?

Heat exchange fins clogged

Outdoor unit fan motor check

Ambient temperature not raised by effect of other heat sources?

Discharged air not sucked in?

Check Point 2 : Check the outdoor unit fan operation,

heat exchanger, ambient temperature

High pressure switch 1 characteristics check.

* For the characteristics of the high pressure switch 1, refer to "Service Parts Information 24".

Check Point 7 : Check high pressure switch 1

Check Point 8 : Check the refrigerant amount

Refrigerant charged amount check

Check Point 6 : Check the solenoid valve (SV1, SV2, SV4)

Check Point 3 : Check the EEV, strainer

Solenoid valve operation check. Refer to "Service Parts Information 18".

OK

OK

OK

OK

OK

OK

Check Point 1 : Check if 3-way valve is open.

If the 3-way valve was closed, open the

3-way valve and check operation.

Check Point 1 : Check if 3-way valve is open.

If the 3-way valve was closed, open the

3-way valve and check operation.

OK

<Cooling/ Cooling main operation> <Heating/ Heating main operation>

EEV (EEV1, EEV2) open?

Strainer clogging check (before and after EEV, ACM, oil return)

Refer to "Service Parts Information 15, 16".

Check Point 4 : Check the 4-way valve (4WV1, 4WV2)

4-way valve operation check. Refer to "Service Parts Information 19".

OK

Check Point 5 : Check the check valve

Check if check valve (oilseparetor (out) of compressor 1) is not clogged.

OK

Caution

By changing of DIP SW 4-2 to ON, the Back-up operation can start when the active

outdoor unit exists on the multi outdoor unit connection.

(Stand alone outdoor unit is impossible)

The following conditions will be concerned in use of back-up operation. (Please do

not use the system with back-up operation for long time.)

- The operating compressor life time becomes shorter.

- The operating performance may drop due to the limited active compressor(s).

- The compressor may stop frequently by protection controlling.

*In order to keep the operating capacity, the release of the Low noise mode setting

might be necessary.

04-73

Loading...

Loading...