Inspecting and Adjusting the

Track Tension

WARNING

If you must work beneath the raised

machine or equipment, always use

wood blocks, jack-stands or other rigid

and stable supports. Never get under

the machine or working equipment

if they are not sufficiently supported.

This procedure is especially important

when working on hydraulic cylinders.

The track adjuster contains highly

pressurized grease. If the tension

is adjusted without following the

prescribed procedure, the grease

discharge valve may fly off, resulting in

injury.

• Loosen the grease discharge valve

slowly.

• Do not put your face, arms, legs or

body in front of the grease discharge

valve.

• If no grease is expelled when the

grease discharge valve is loosened,

there is a problem. Contact your

Gehl dealer for repairs. DO NOT

disassemble, because this is very

dangerous.

Inspection

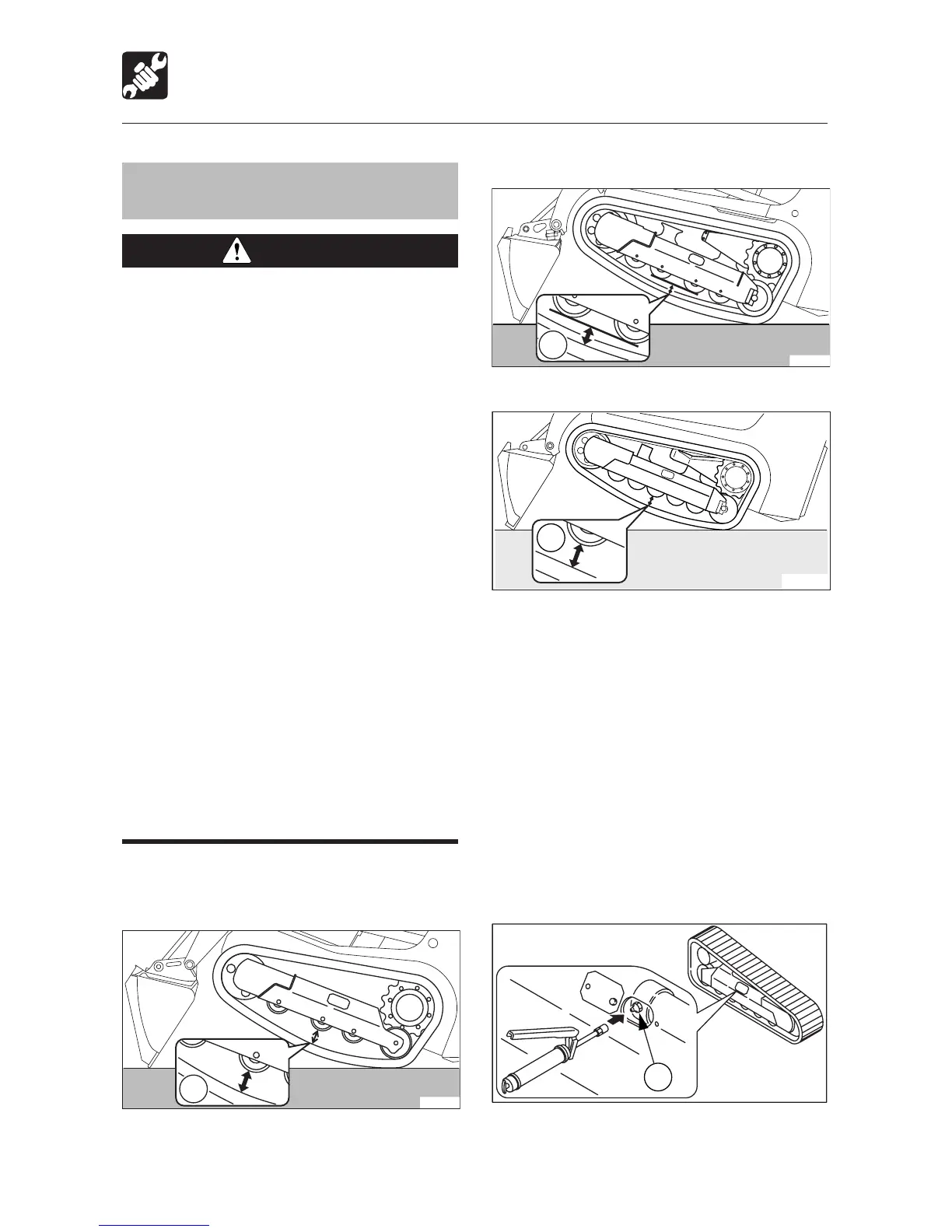

< CTL55 >

< CTL65 / CTL75 >

< CTL85 >

1. Lower the lift arm and tilt the bucket

forward to raise the front of the loader off

the ground as far as it will go.

2. Measure the clearance between the

center track roller and the surface of the

track where it makes contact with the

roller.

The gap (A) should be within the following

range:

25 to 50 mm (1 to 2 in.)

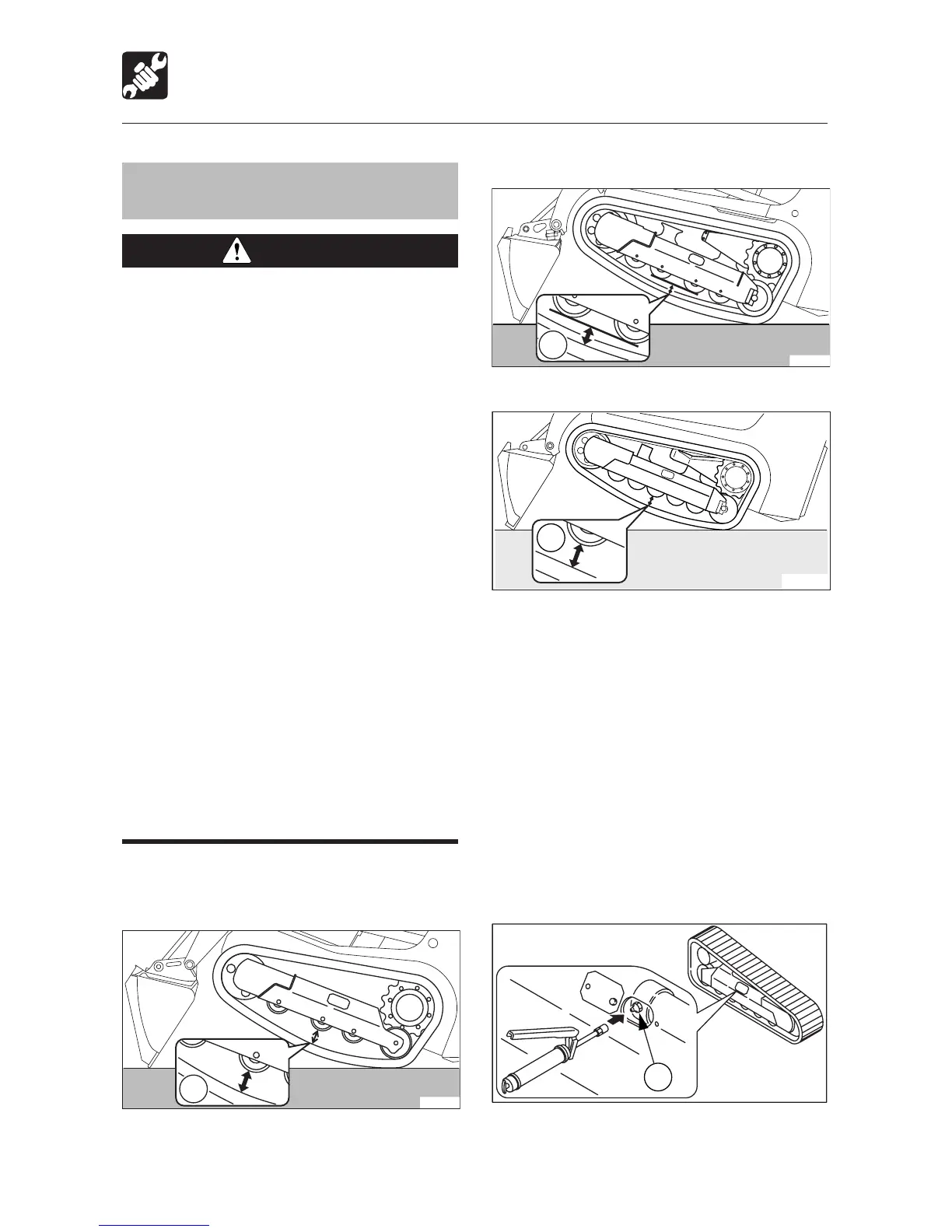

Adjustment

Increasing the tension

1. Remove the cover.

Every 50 Hours

Loading...

Loading...