Transporting Precautions

Load and unload the machine

safely

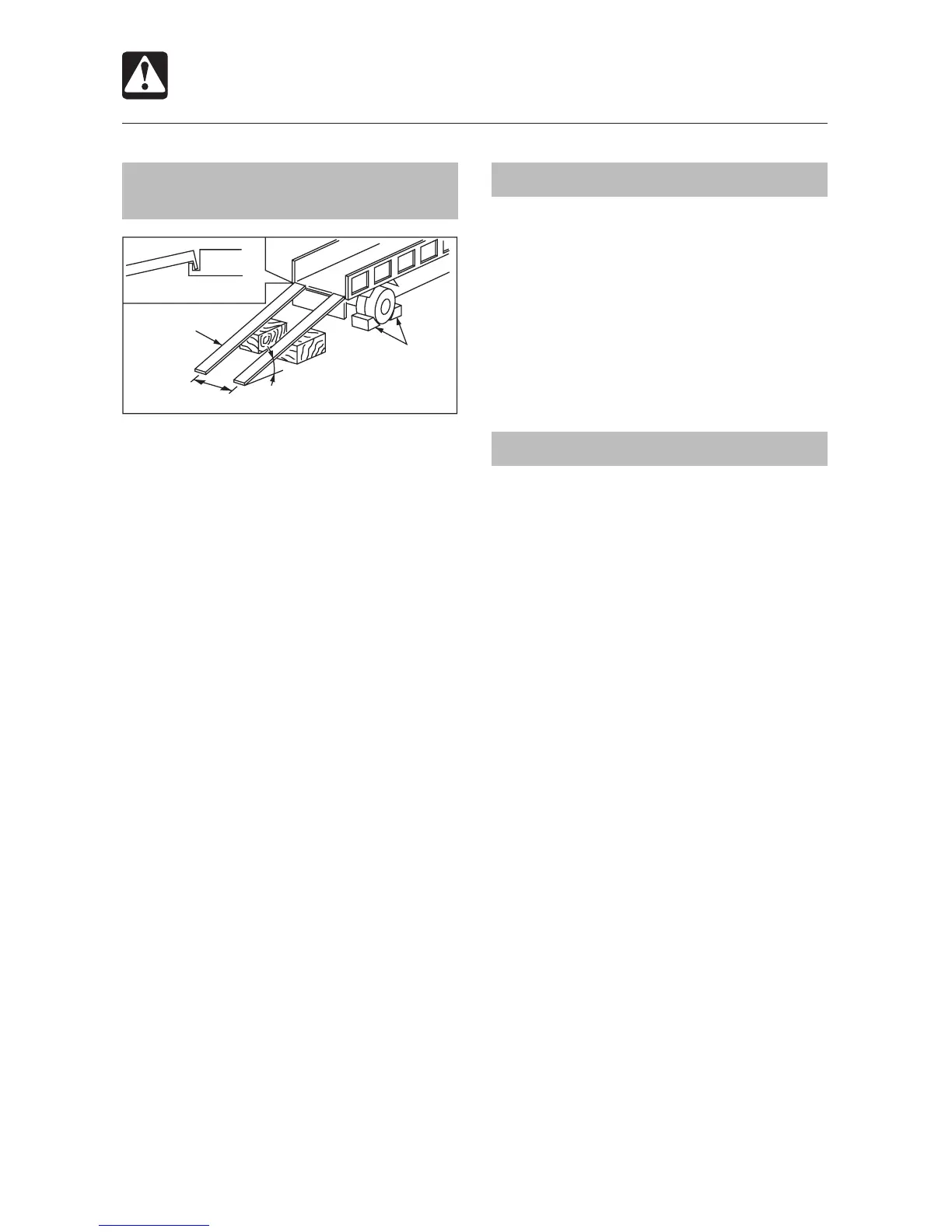

The machine may roll or tip over or fall while

loading or unloading it. Take the following

precautions:

Select a firm, level surface and keep

sufficient distance from road shoulders.

Use loading ramps of adequate strength

and size. Maintain the slope of loading

ramps to 15 degrees or less.

Secure the ramps to the truck bed.

Keep the truck bed and loading ramps

clean of oil, clay, ice, snow, and other

materials that can become slippery. Clean

the tracks.

Block the transport vehicle so it cannot

move.

Use a signal person when loading and

unloading the machine, and travel slowly

in first gear (low speed).

Never change course on the ramp.

Do not turn on the ramps. The machine

may tip over.

Block both tracks and secure the machine

to the truck bed with load binders.

Transport the machine safely

Know and follow the safety rules, vehicle

code and traffic laws when transporting

the machine.

Consider the length, width, height and

weight of the truck with the machine

loaded on it when determining the best

route.

Hoisting the machine safely

Know and use correct crane signals.

Inspect the hoisting equipment daily for

damaged or missing parts.

When hoisting, use a wire rope with

sufficient strength with respect to the

machine’s weight.

Do not hoist the machine with an operator

on it.

When hoisting, hoist slowly so that the

machine does not tip.

Keep all other persons out of the area

when hoisting. Do not move the machine

over the heads of the persons.

Do not hoist with the machine in a position

other than the one described in the

procedure below. Doing so is dangerous

because it may result in the machine

losing its balance.

Refer to the section titled “Hoisting the

Machine” for further details.

Fasten to the suspension fitting

Ramp

15° or less

Distance between ramps

Stopper

Loading...

Loading...