23 - 2

Loader Valve - Pressure Testing

Unloader Valve

Make sure that the hydraulic oil is at working temperature,

i.e. 50°C (122°F).

Lower the backhoe bucket and loader shovel to rest on the

ground; stop the engine; operate the control levers to vent

residual hydraulic pressure.

Make sure that the ‘hydraulic speed control’ and ‘smooth

ride system’ facilities are NOT switched on, otherwise the

correct unloader valve pressure cannot be obtained.

If the machine has a front-mounted roadbreaker, ensure that

the roadbreaker control valve lever is in the 'off' position

(lever down), otherwise the roadbreaker relief valve will

operate and prevent unloader valve pressure from being

reached.

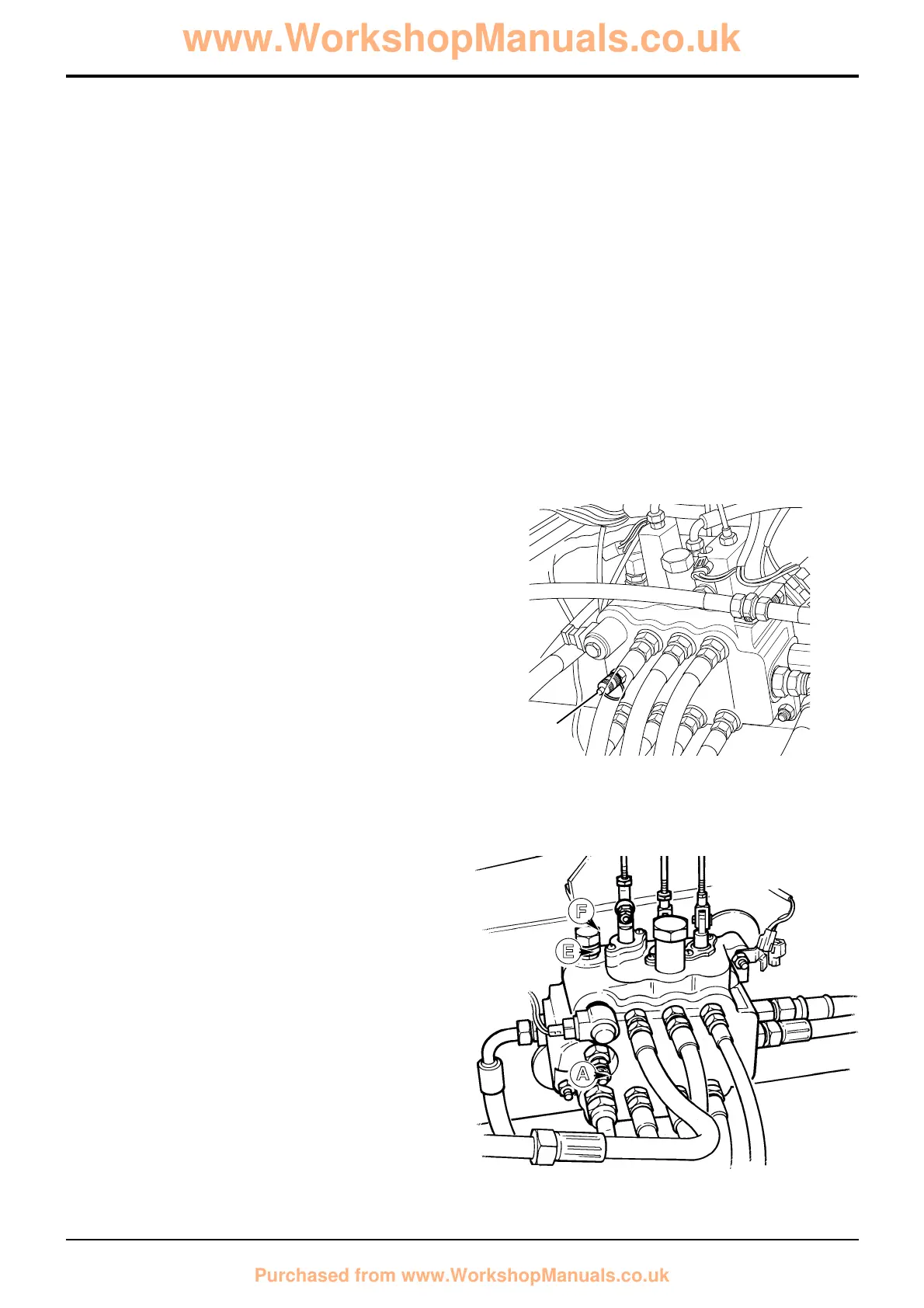

1 Connect a 0 - 400 bar (0 - 6000 lbf/in

2

) pressure gauge

to pressure test connector A.

2 With the engine running at 1500 revs/min, slowly

operate arms raise or lower.

Note 1: The arms raise or lower service is specified because

it has no auxiliary relief valve (A.R.V.). Selecting this service

ensures that the pressure vents through the M.R.V. and not

an A.R.V.

3 When the service reaches full travel, return the lever to

the neutral position. Select the service again, very

slowly, the pressure gauge will rise until a step/kick is

seen in the rate of change in the pressure increase. This

is the start of unloader operation. Keep selecting the

service until a sudden sharp increase in pressure is

observed with a change of engine sound, this point is

the unloader setting and should be as specified in

Technical Data.

4 If the pressure is incorrect, slacken locknut E and

adjust cap F. Turn it clockwise to increase pressure and

anti-clockwise to decrease the pressure. When the

pressure is correct, tighten the locknut and check the

pressure again. Adjust as required.

If the correct pressure cannot be achieved, add or

subtract shims as required, refer to Loader Valve -

Fixed Flow, Dismantling and Assembly - Unloader

Valve.

Section E

Hydraulics

9803/3280

Section E

23 - 2

Issue 1

Service Procedures

S266300

E

F

A

Loading...

Loading...