94 - 3

Drive Head-Assembly

Pinion Depth

Determine the pinion depth setting as follows:

Note: See page Crownwheel and Pinion for general

guidance on crownwheel and pinion adjustment.

1 Assemble the pinion inner bearing and its cup on a flat

surface.

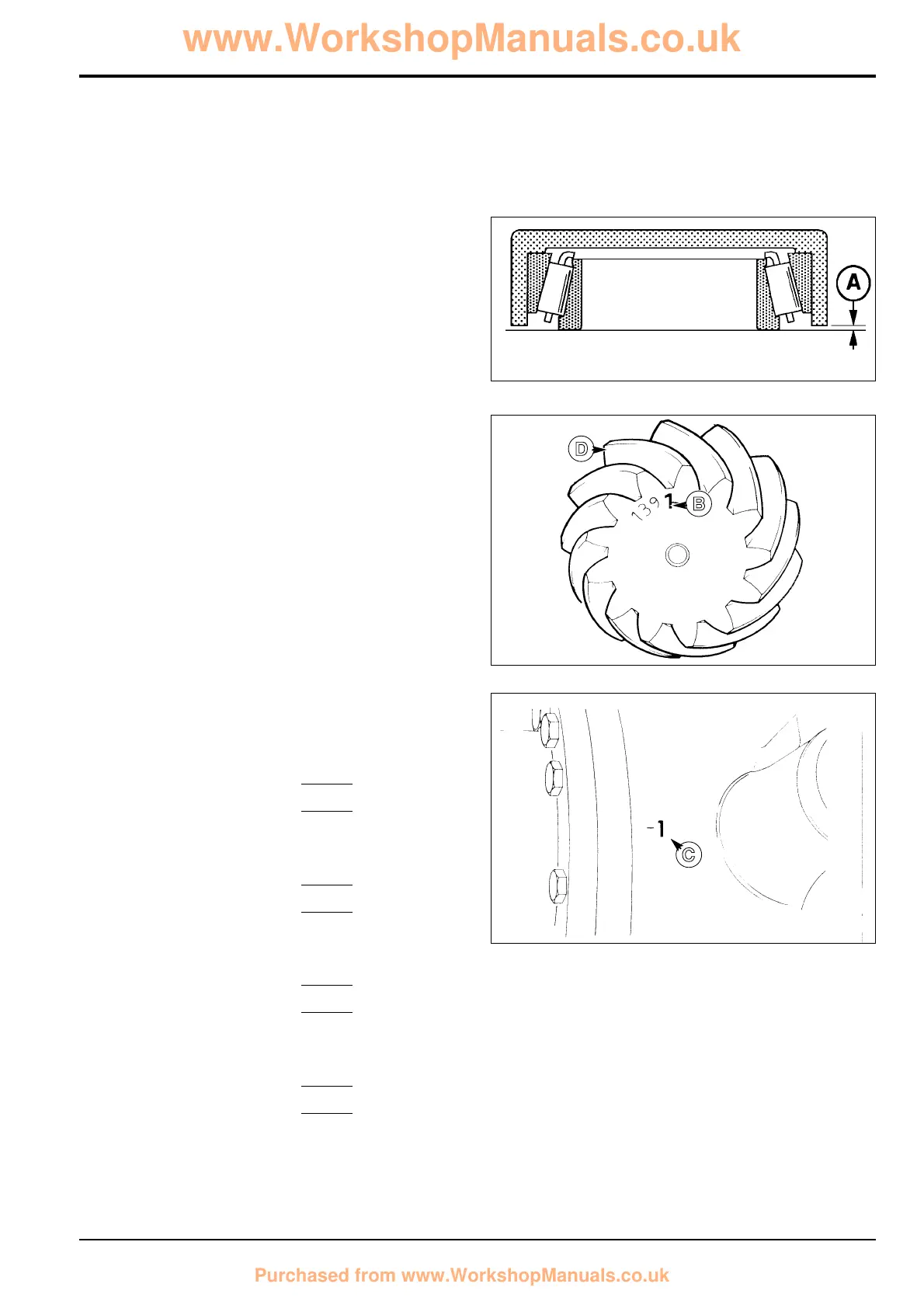

2 Place Service Tool 892/00174 over the bearing assembly.

Measure gap A. Add tool depth (30.01 mm) to gap A to

give bearing depth.

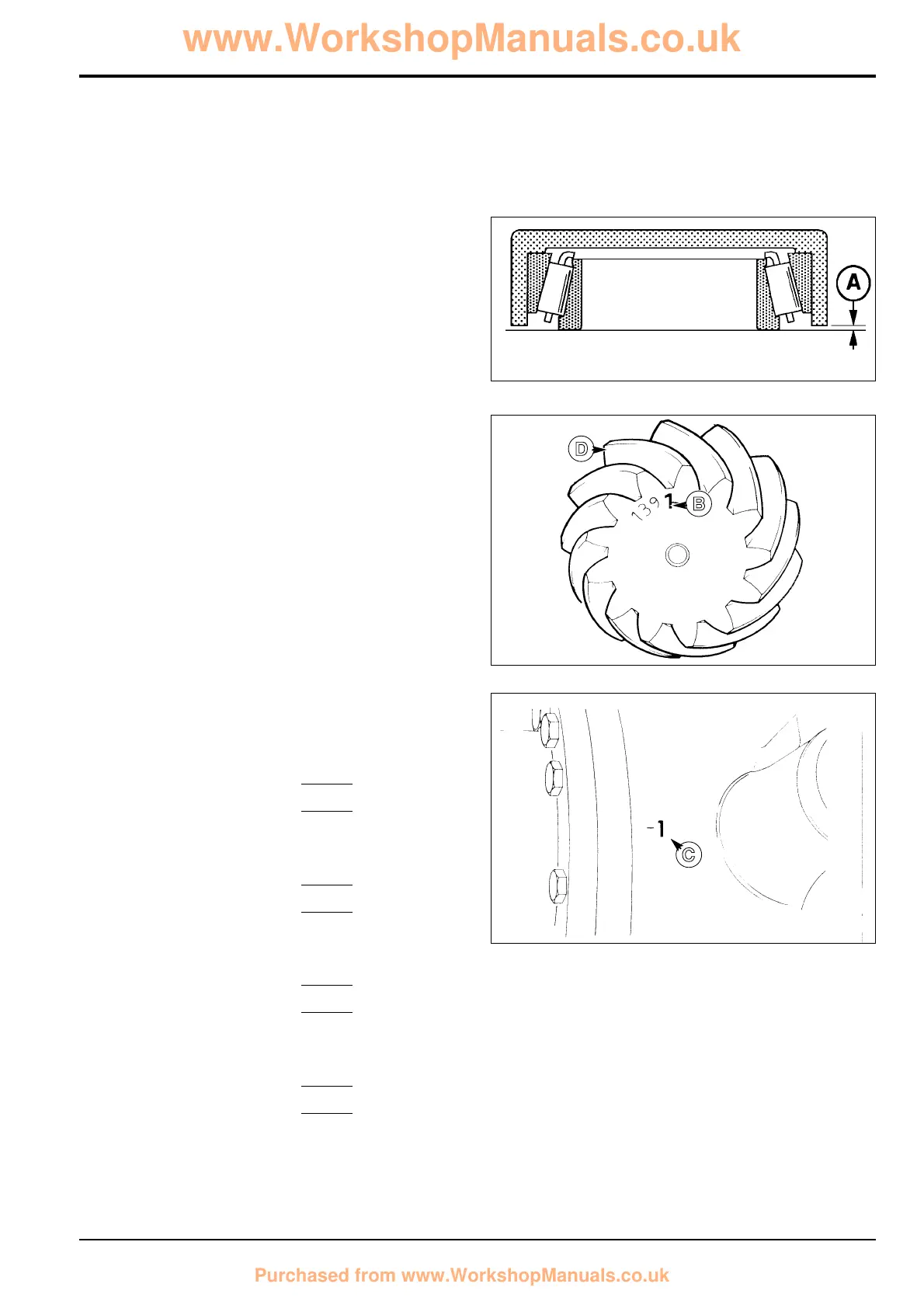

3 Note the mounting distance figure B etched on the pinion

and the deviation figure C on the drive head housing.

Both figures are in units of 0.01 mm.

Note: The pinion depth may be etched on the gear face B or

on the rear of a gear tooth D.

4 If dimension B is positive, add it to the bearing depth. If

dimension B is negative, subtract it from the bearing

depth.

5 If dimension C is positive, subtract it from the total. If

dimension C is negative, add it to the total.

6 Subtract the result from the standard value of 31.19 mm

to give the required shim thickness.

Example (Dimensions in mm)

Dimension A 0.25

Add tool depth + 30.01

Total 30.26

Add dimension B if positive.

(Subtract if negative.) + 0.01

Total 30.27

Add dimension C if negative.

(Subtract if positive.) + 0.01

Total 30.28

Standard Value 31.19

Less calculated total from above - 30.28

SHIM THICKNESS 0.91

Section F Transmission

9803/3280

Section F

94 - 3

Issue 1

Rear Axle - SD80, PD70

S256110

S256120

B

C

S184400

D

Loading...

Loading...