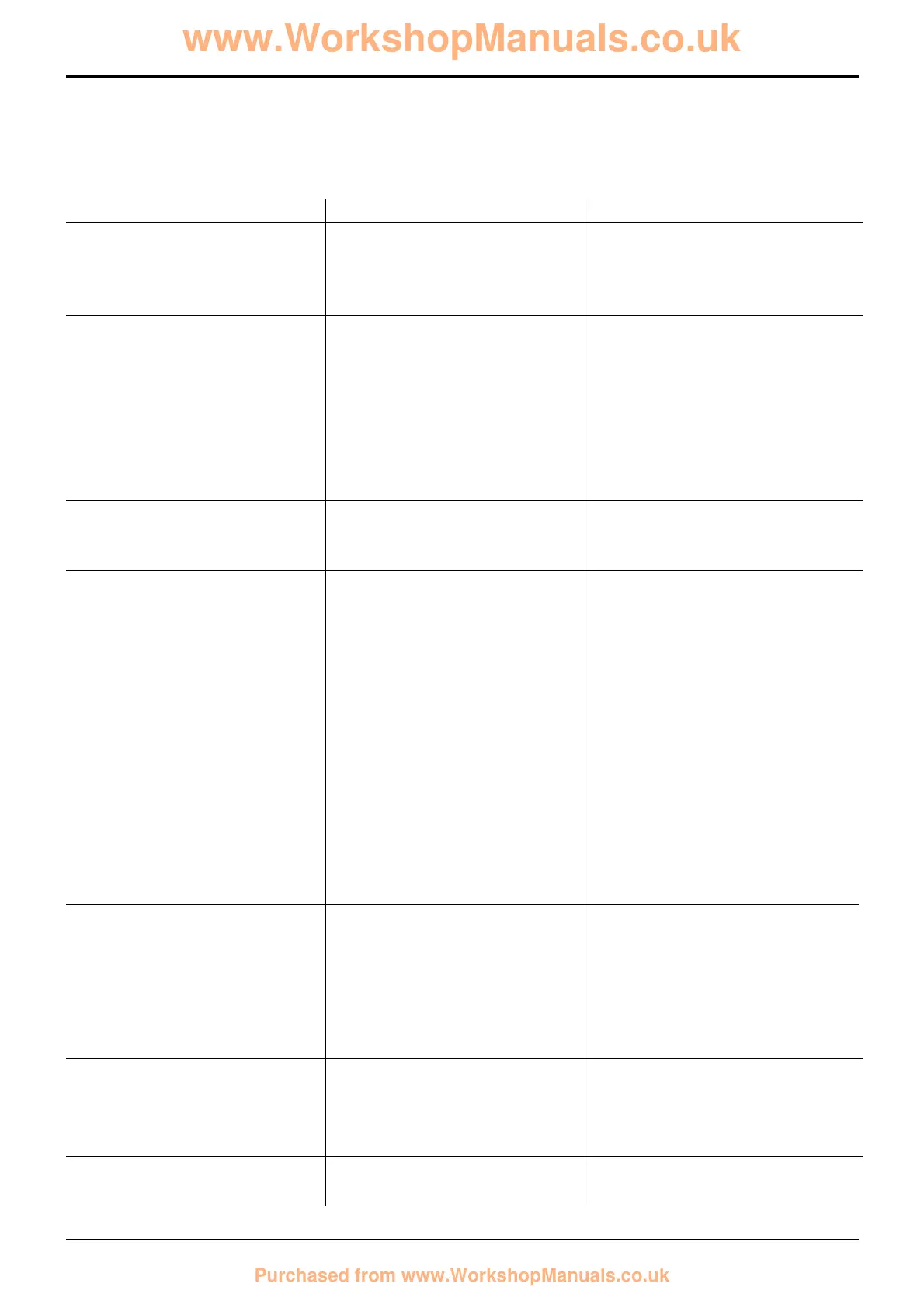

10 - 1

FAULT

A One or both brakes do not apply.

(Brake travel not excessive, brakes

not pulling to one side).

B Pedal travel excessive (but not

touching floor).

C Applying one brake (pedals

unlocked) also partially engages

the other brake.

D Pedal hard to operate.

E Pedals touch floor under constant

pressure - no fluid loss.

F Pedals touch floor under constant

pressure - and fluid loss.

G Pulling to one side when pedals

locked together.

Brake System

Note: The brakes generate a high temperature when operating, this means that the casing will be hot to touch, this condition

is normal. Note aslo that 4WS machines do not have dual pedal braking.

POSSIBLE CAUSE

1 Master cylinder fault.

2 Friction/counter plate distortion.

1 Air in hydraulic system.

2 Leak in hydraulic system.

3 Friction/counter plate distortion.

1 Valve stem seal inside (non-active)

master cylinder piston not sealing.

1 Tightness at pedal pivot.

2 Fluid contamination/seal damage.

3 Misaligned push rod/pedal.

4 Kinked or crushed brake pipes.

Items 5 to 7 are for machines fitted

with servo assisted brakes only:

5 Vacuum failure due to low vacuum

at source.

6 Blocked/leaking vacuum pipe.

7 Servo defect.

1 Master cylinder fault.

2 Friction/counter plate distortion.

3 Air in hydraulic system.

1 External fluid leaks.

2 Internal fluid leaks.

1 Compensating feature not

working.

ACTION

1 Check master cylinder in single and

coupled pedal modes to identify fault

area, service as required.

2 Check friction/counter plates.

1 Check fluid reservoir level. Check for

fluid/air leaks, rectify as required.

2 Check for fluid loss at master

cylinder and brake piston, all pipes

and fittings for loose connections.

Rectify as required.

3 Renew friction/counter plates -

BOTH sides.

1 Renew master cylinder piston.

1 Inspect pedal pivot. Free-

off/lubricate.

2 Flush system and renew all hydraulic

seals.

3 Check and rectify as required.

4 Check/renew brake pipework.

5 Inspect/service engine mounted

exhauster unit as required.

6 Check/renew vacuum pipe.

7 Renew servo unit.

1 Check master cylinder in single and

coupled pedal modes to identify fault

area, service as required.

2 Renew friction/counter plates -

BOTH sides.

3 See item B.1.

1 Visually check brake circuit for fluid

loss, service as required.

2 Refer to Service Procedures -

Brake Piston Seal Leakage Test.

1 Inspect master cylinder

compensating operation. Check if

blockage in bridging pipe. Service as

required.

Section G Brakes

9803/3280

Section G

10 - 1

Issue 1

Fault Finding