112-4

Section F Transmission

9803/3280

Section F

112-4

Issue 2*

Synchro Shuttle Gearbox

Assembly (cont'd)

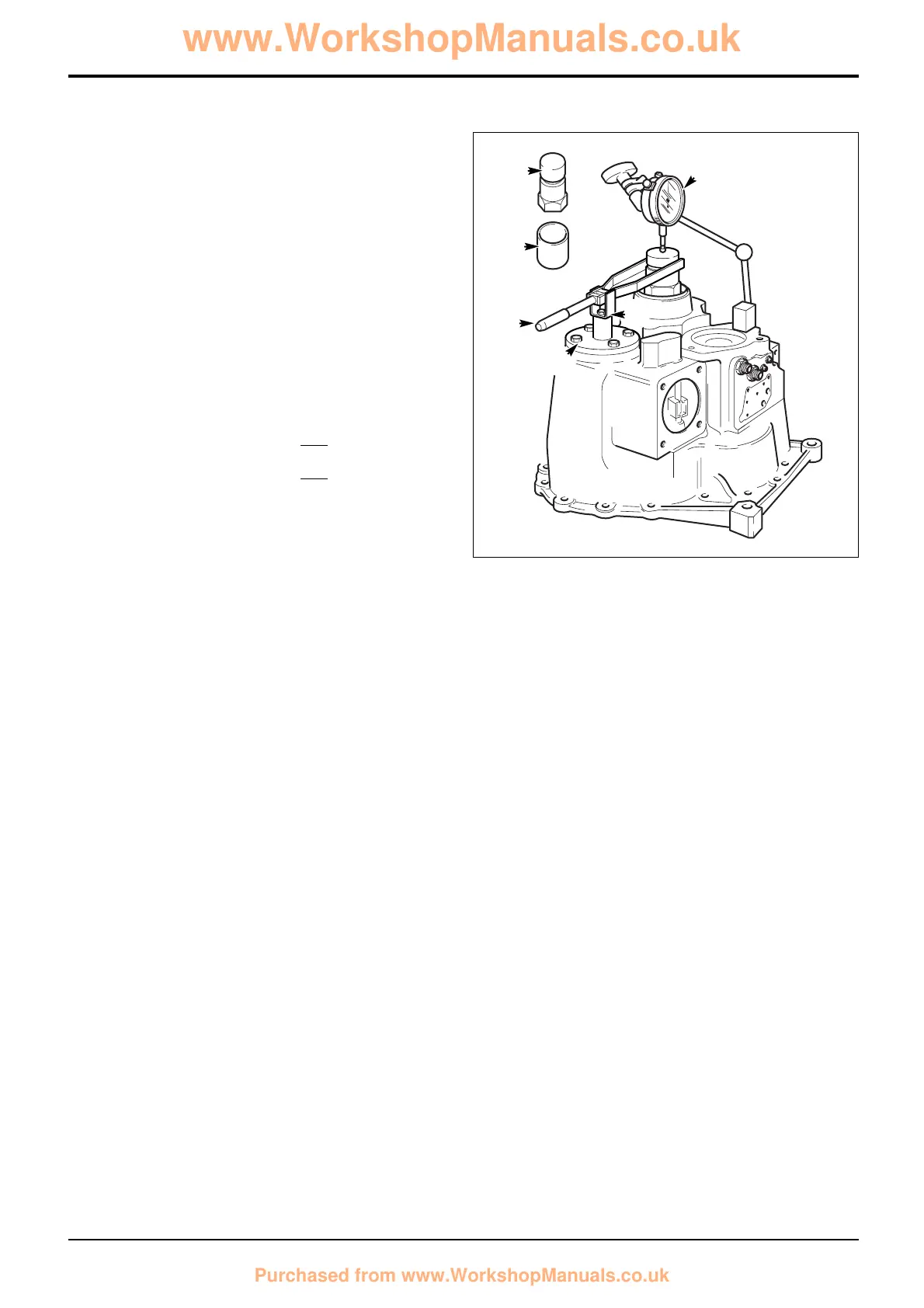

11 a Fit dial test indicator E (DTI) .

b Set torque wrench F to 35 Nm and measure the end

float while rotating the output shaft.

c To select the right size spacer, subtract the end

float obtained at step 11b from the solid spacer

(13.70 mm). Also subtract 0.120 mm to allow for

theoretical bearing tolerance and pre load. If there is

no spacer of this size, fit the next smallest spacer.

Example

Service spacer 13.70

Subtract end float 0.41

Total 13.29

Subtract tolerance & preload 0.12

Result 13.17

Use next smallest spacer ie. 13.15

d Remove special nut B and sleeve A. Remove rear

bearing and 13.70 mm spacer. Fit correct size

spacer (Do no fit the oil seal at this stage). Take care

to avoid damaging the outer bearing.

e Fit sleeve A and initially tighten nut B to 50 Nm (36.9

lbf ft). Check there is no end float and rolling torque

less than 1.5 Nm (1.0 lbf ft). If the rolling torque

exceeds 1.5 Nm (1.0 lbf ft) check that the output

shaft has been assembled correctly.

f If the rolling torque measured is too high, fit the next

larger size spacer. If there is end float, fit the next

smaller size spacer.

Loading...

Loading...