13 Lift off spring retaining plate 20.

14 Remove the spring 21 and oil baffle 22.

15 Turn the assembly over and knock the clutch shaft on a

piece of aluminium (or wood) to loosen the piston 23.

Note: If the piston does not loosen when the clutch shaft is

knocked on aluminium, then hand pump air down the shaft

oil inlet hole.

14 Remove the piston 23. Remove and discard the piston

'O' ring 24 and shaft 'O' ring 25.

133- 2

Section F Transmission

9803/3280

Section F

133 - 2

Issue 1

Powershift Gearbox

1 Carefully remove piston ring seals 1 at each end of the

shaft.

Note: If the piston ring seals are excessively worn then

check for burrs or damage on shaft grooves. If necessary

remove burrs with a fine grade abrasion paper and oil.

2 Remove taper roller bearing 2 using a collet tool and

press.

3 Withdraw the gear 3. Make a note which way round the

gear is fitted for assembly.

4 At the opposite end, remove the clutch end bearing 4

using a puller.

5 Withdraw the gear and splined hub 5 together with thick

thrust washer 6, thrust bearing 7 and thin thrust washer

8.

6 Remove the needle roller bearing 9.

7 Remove the thin thrust washer 10, thrust bearing 11

and thick thrust washer 12.

8 Remove the clutch friction/counter plates retaining

circlip 13.

9 Remove pressure end plate 14 and shim 15, if fitted.

10 Remove the clutch friction plates 16 and counter plates

17. Keep them together in sets, DO NOT mix the plates

with those from other clutches.

11 Remove the disc spring assembly 18.

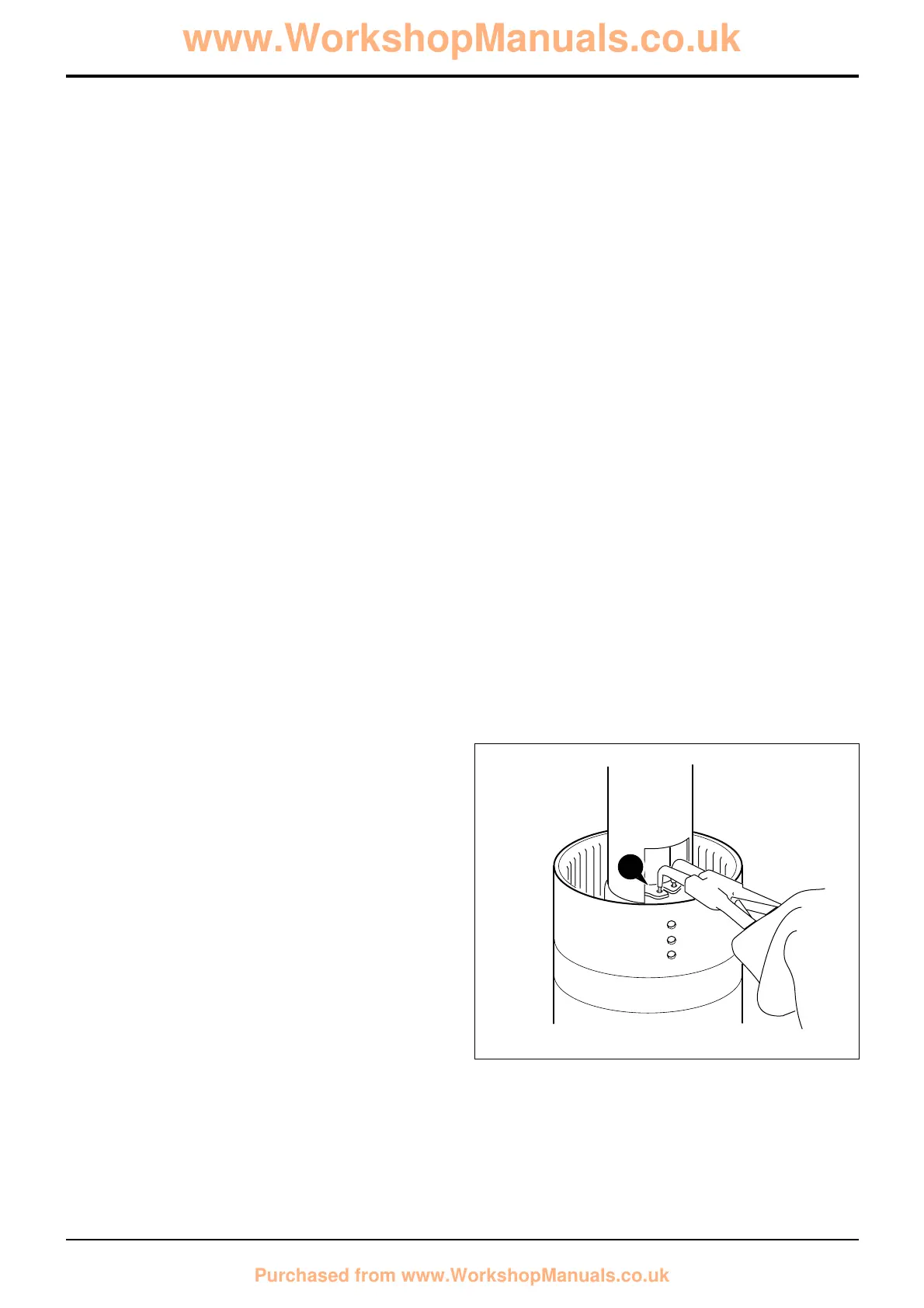

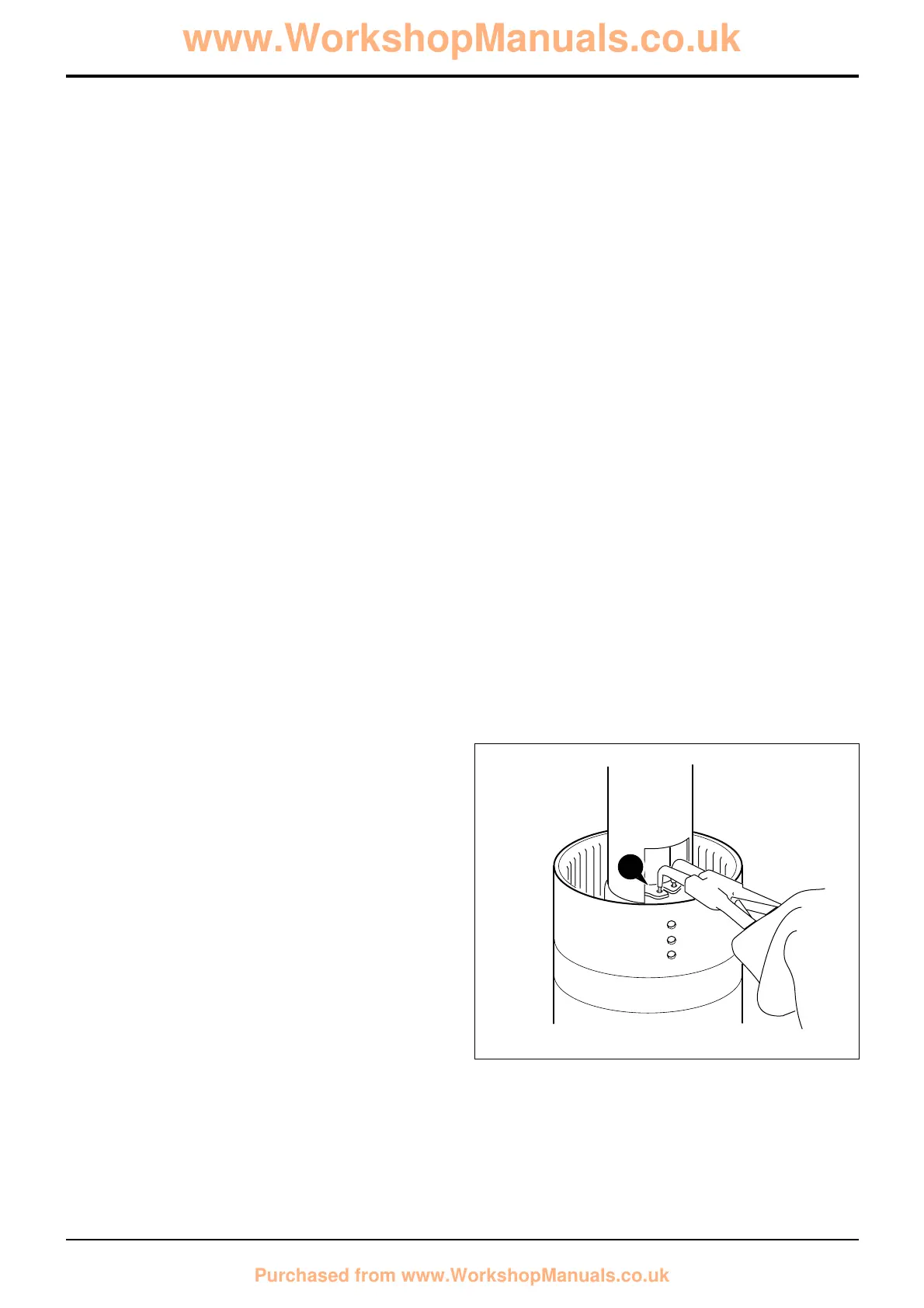

12 Position clutch assembly in a suitable press, with a cut

away tube compress the piston spring as shown, then

remove circlip 19.

PS760 - 6 Speed Clutch - Dismantling

Loading...

Loading...