− 50 −

(2) With regard to lubrication

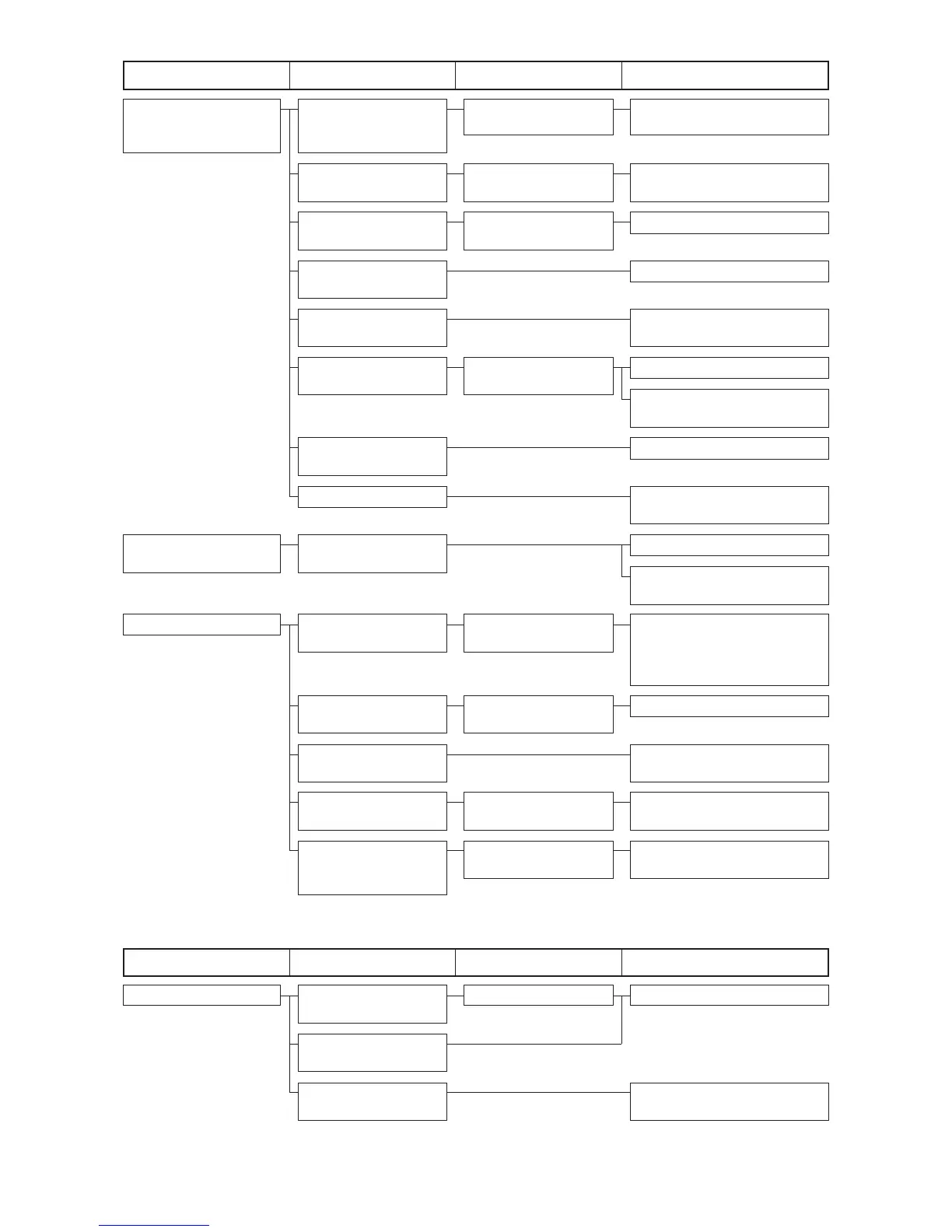

Loose stitches

(Balloon stitches or isolated

idling loop)

Loose stitches

(Needle thread rises.)

Irregular stitches

Bobbin thread is not

passed to the fork end of

bobbin case tension spring.

Thread paths have been

poorly finished.

Bobbin fails to move

smoothly.

Bobbin case is improperly

engaged.

Thread is not well tightened

in the reverse feed.

Height of the feed dog is too

high.

Feed timing is excessively

advanced.

Hard-to-slip thread is used.

Needle thread has not

been fully pulled up.

Stroke of the thread take-

up spring is improper.

Thread paths have been

poorly finished.

Bobbin thread tension is too

low.

Bobbin has been wound

too tight.

Pressure of the idle

prevention spring is too

high.

Check the bobbin thread

route.

Check the finish of the

respective thread paths.

Check the change of

bobbin thread tension.

Compare the height with

the standard value.

Check the stroke of the

thread take-up spring.

Check the finish of the

respective thread paths.

Check the state of bobbin

winding.

Check the idling amount of

the bobbin.

Correctly pass thread to the bobbin

case.

Finish using a fine emery paper or

buff.

Replace the bobbin or the hook.

Replace the bobbin case or the hook.

Use the optional walking foot and

presser foot.

Refer to “(4) Height of the feed dog”.

Lower the height by 0.2 mm than the

standard value.

Retard the feed timing.

Use silicone oil.

(Refer to “(4) Others *”).

Increase the needle thread tension.

Use the optional walking foot.

(Top-devided type)

Adjust the thread take-up spring to

move to approximately 1 mm from

the initial position when hook draws

thread maximumly.

Finish with a fine emery paper or buff.

Increase the tension of the bobbin

thread.

Decrease the tension applied to the

bobbin winder.

Decrease the pressure of the idle

prevention spring.

Troubles Causes Checking Corrective measures

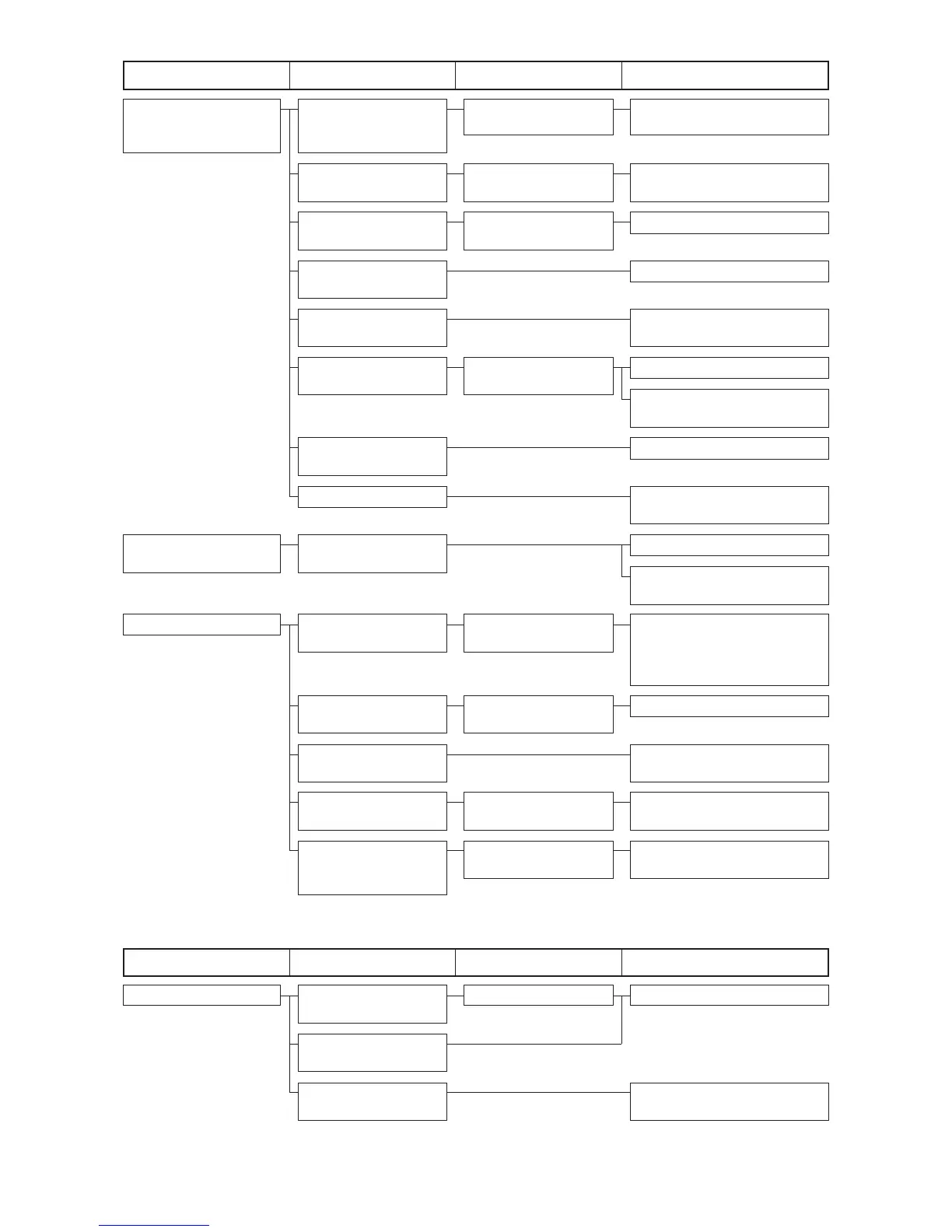

Troubles Causes Checking Corrective measures

Oil does not enter the hook. Oil amount in the oil tank is

too small.

Oil amount adjusting screw

is improperly adjusted.

Lead groove in the hook

shaft is clogged with dust.

Check the oil level. Refer to “(15) Lubrication”.

Draw out the hook shaft and wash

the lead groove.

Loading...

Loading...