− 52 −

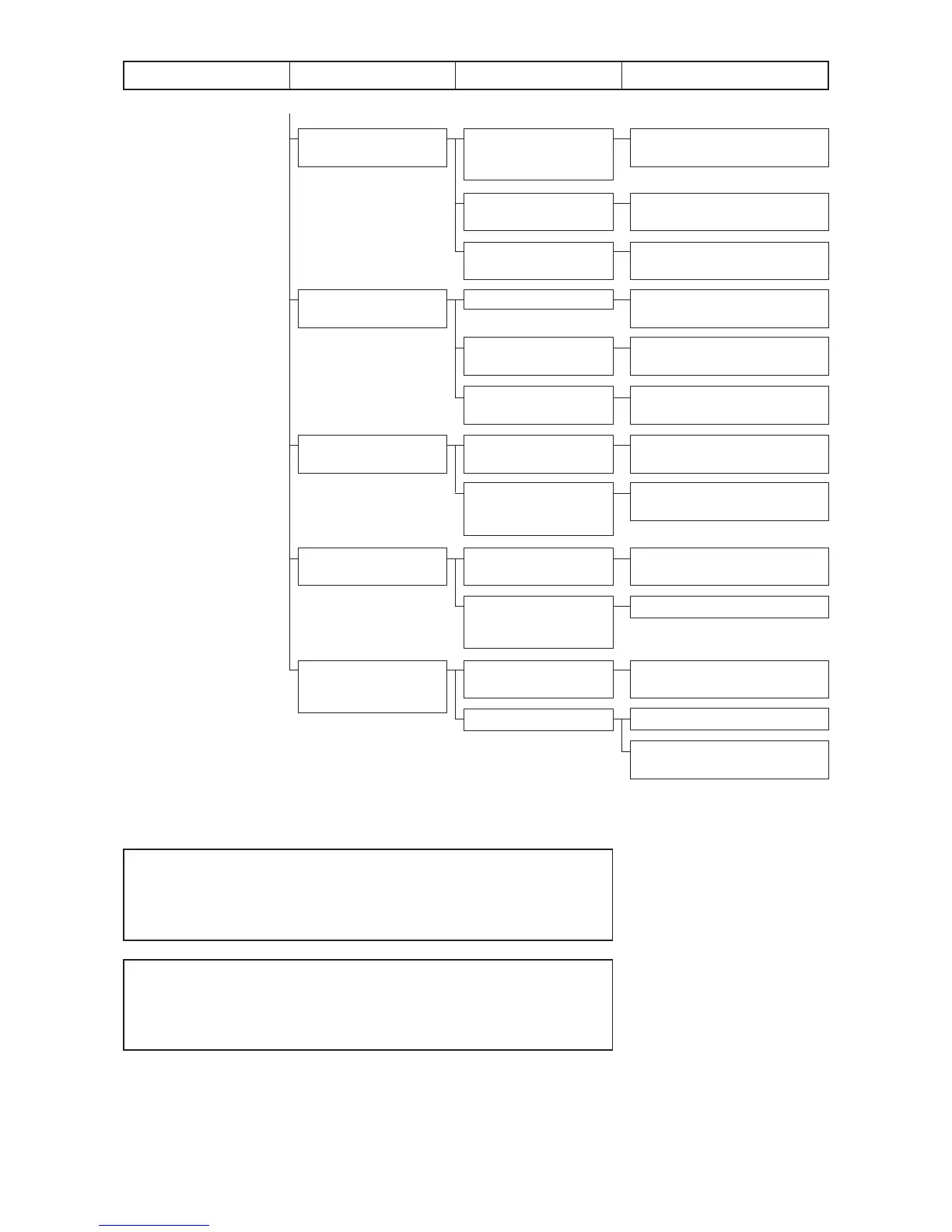

(4) Others

Thread remains uncut

after thread trimming.

Rotary knife stops during

operation.

Needle thread is not

caught.

Bobbin thread is not

caught.

Both needle and bobbin

threads cannot be

trimmed.

The blades of rotary knife

and fixed knife have

worn out or broken.

Check whether a

synthetic thread is used.

Pressure of the fixed

knife is insufficient.

Thread is too thick.

Thread trimming timing is

excessively retarded.

Pressure of the knife is

too high.

Check the thread

trimmer cam timing.

Top end of the rotary

knife has broken or been

scratched.

Check the routing of

bobbin thread.

Top end of the rotary

knife has broken or been

scratched.

Pressure of the knife is

too low.

Rotary knife fails to work.

Replsace the rotary knife or fixed

knife with a new one.

Refer to “3. (1)-3) Thread trimmer

cam timing”.

Refer to “3. (1)-4) Rotary knife and

fixed knife”.

Use a thread within the specified

value.

Refer to “3. (1)-3) Thread trimmer

cam timing”.

Refer to “3. (1)-4) Rotary knife and

fixed knife”.

Refer to “3. (1)-3) Thread trimmer

cam timing”.

Replace the fixed knife with a new

one.

Correctly thread the bobbin

thread.

Replace the rotary knife.

Refer to “3. (1)-4) Rotary knife and

fixed knife”.

Adjust the synchronizer timing.

Replace the thread trimmer

solenoid.

Troubles Causes Checking Corrective measures

From the next page

* Use separately available “21144308 Needle thread lubricator”

“B1114012000 Thread guide bar”

“B91351230B0 Silicone oiler”

Adjustment of the thread take-up spring

¡ Decrease the tension of the thread take-up spring and decrease

the stroke of the spring to improve irregular stitches.

Loading...

Loading...