–

179

–

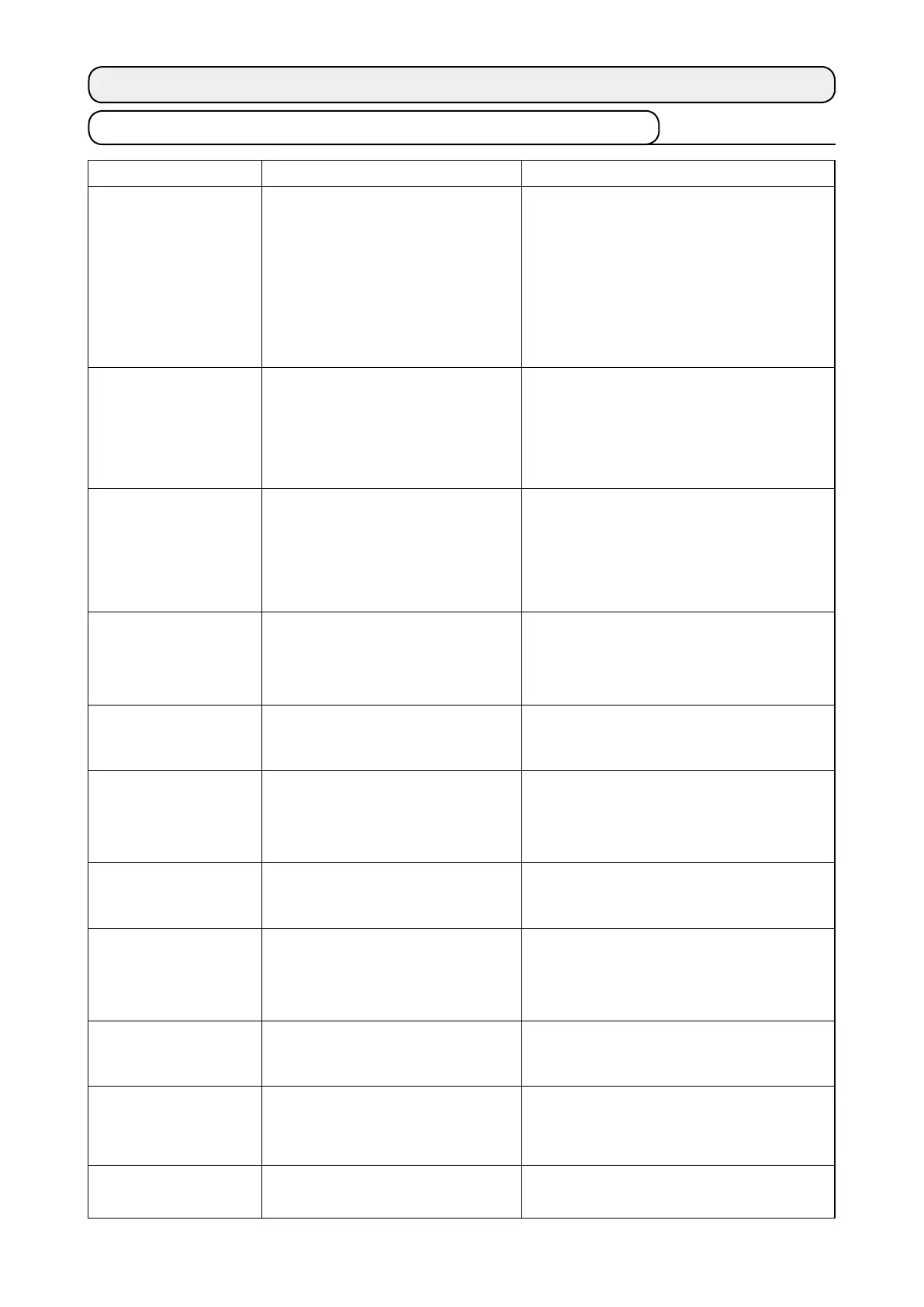

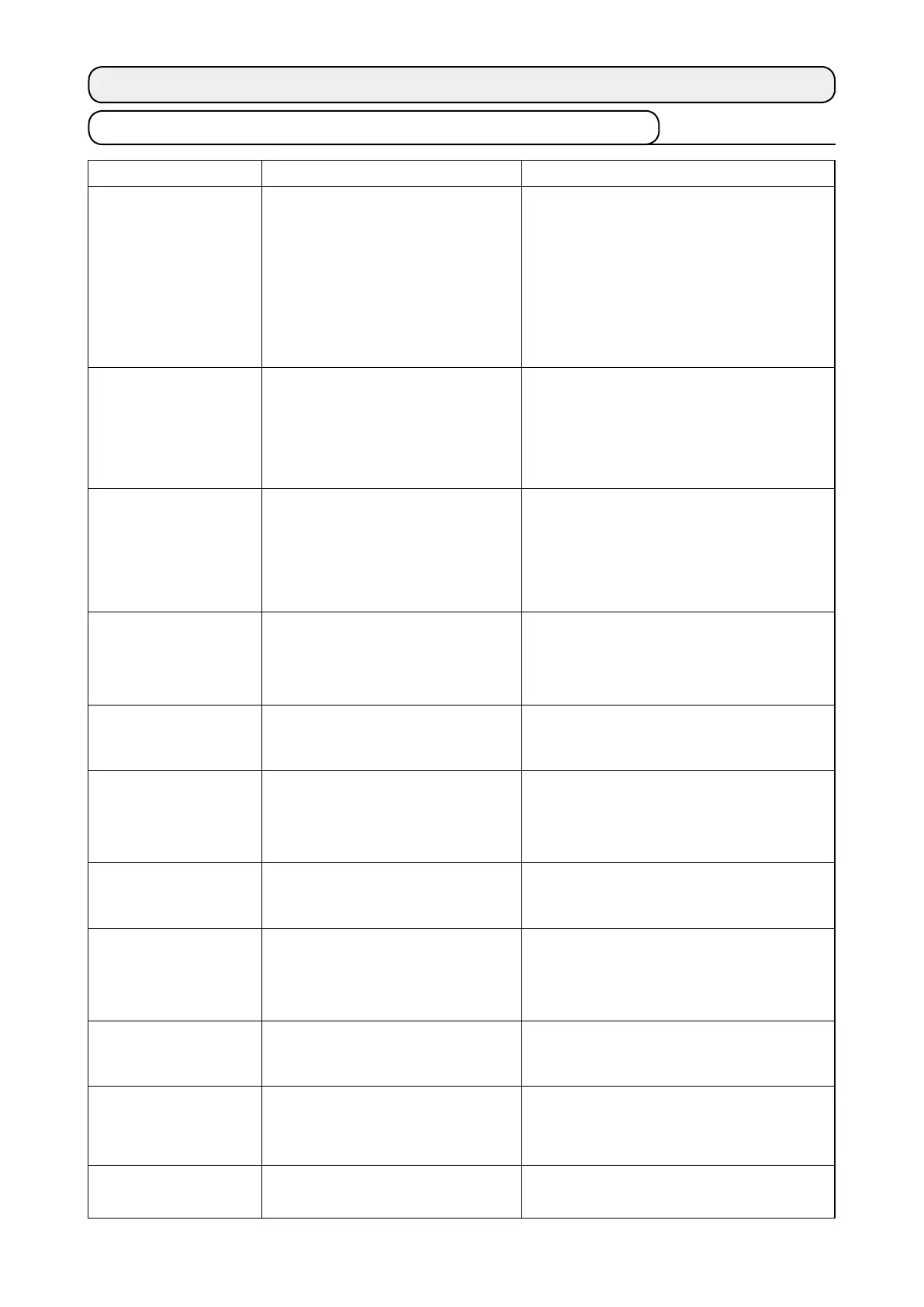

25-1 Troubles in sewing and the corrective measures

25. OTHERS

Troubles

Causes Corrective measures

1.

Thread breakage

1

Thread path, needle point, hook blade point

or bobbin case resting on the throat plate

has sharp edges or burrs.

2

Needle thread tension is too high or too low.

3

Needle comes in contact with the blade point

of hook.

4

Thread take-up spring works excessively or

the stroke of the spring is too small.

5

Timing between the needle and the hook is

excessively advanced.

6

Bobbin idling amount is too large.

™

Remove the sharp edges or burrs on the blade point of

hook using a ne emery paper. Buff up the bobbin case

resting groove on the throat plate.

™

Adjust the needle thread tension.

™

Refer to "Adjusting the needle and the hook".

™

Decrease the tension of the thread take-up spring and

increase the stroke of the spring.

™

Refer to "Adjusting the needle and the hook".

™

Increase the spring pressure.

2. Stitch skipping

1

The clearance provide between the needle

and the blade point of hook is too large.

2

Timing between the needle and the hook is

excessively advanced or retarded.

3

Pressure of the presser foot is too low.

4

Height of the walking foot or presser foot is

too high.

™

Refer to "Adjusting the needle and the hook".

™

Refer to "Adjusting the needle and the hook".

™

Tighten the presser spring regulator.

™

Refer to "Adjusting the height of the walking foot and

the presser foot".

3. Loose stitches

1

Bobbin thread is not put in the fork end of the

thread tension spring of the bobbin case.

2

Thread path has been poorly nished.

3

Bobbin fails to move smoothly.

4

Bobbin thread tension is too low.

5

Bobbin has been improperly wound.

™

Thread the bobbin case properly.

™

Grind the thread path using a ne emery paper. Buff up

the thread path.

™

Replace the bobbin.

™

Adjust the bobbin thread tension.

™

Refer to "Winding a bobbin".

4. Thread slips off the

needle

eyelet

simultaneously

with

thread trimming.

1

Returning force of the thread take-up spring

is too strong.

2

Thread tension given by the thread tension

controller No. 1 is too high.

3

Position of the counter knife is improper.

™

Refer to "Threading the machine head".

™

Refer to "Threading the machine head".

™

Refer to "Adjusting the thread trimmer".

5. Needle thread is not

rimmed. Bobbin thread is

trimmed.

1

Stitch skipping at the last stitch (Clearance

provided between the needle and the hook is

excessive.)

™

Refer to "Adjusting the needle and the hook".

6. Both needle thread and

bobbin thread are not

trimmed.

1

Thread trimming timing is improper.

2

Breakage of the knife

3

Pressure of the knife is insufcient.

4

Moving amount of the moving knife is

insufcient.

™

Adjust the thread trimming timing.

™

Replace the knife.

™

Adjust the pressure of the knife.

™

Adjust the initial position of the moving knife.

7. Thread is not cut sharply.

1

Thread trimming timing is improper.

2

Pressure of the knife is insufcient.

3

The knife has a blunt blade.

™

Adjust the thread trimming timing.

™

Adjust the pressure of the knife.

™

Replace the knife.

8. Material bends.

1

Top feed belt is bent.

2

Height of the main walking foot and the

auxiliary walking foot is improper.

3

Auxiliary feed shirring amount set value is

improper.

™

Adjust the walking foot.

™

Make the height of the main walking foot and the

auxiliary walking foot same.

™

Adjust the set value.

9. Feed pitch is not obtained.

1

Feed belt has been worn out.

2

Walking foot is excessively raised.

3

Belt tension is too low.

™

Replace the belt.

™

Refer to "Adjusting the height of the walking foot".

™

Adjust to the proper tension value.

10. Shirring is not performed.

1

Feed belt has been worn out.

2

Walking foot is excessively raised.

3

Belt tension is too low.

4

Set value is too small.

™

Replace the belt.

™

Refer to "Adjusting the height of the walking foot".

™

Adjust to the proper tension value.

™

Adjust to the optimum set value.

11.Shirring is excessively

performed.

1

Set value is too large.

™

Adjust to the optimum set value.

Loading...

Loading...