E 23

0803.GB

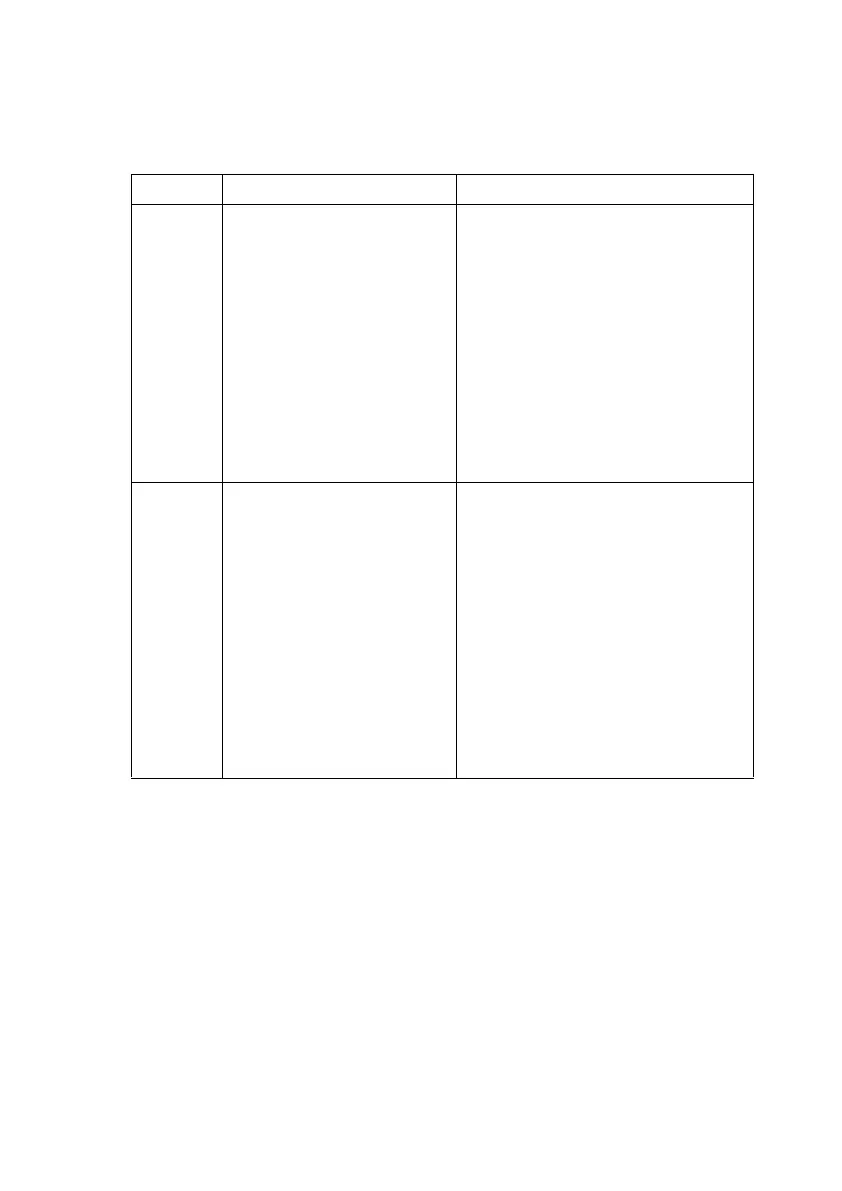

6 Fault location

This chapter enables the operator to locate and rectify minor faults and malfunctions,

or the effects of operating errors. When trying to locate a fault, proceed in the order

shown in the table.

A

If the fault could not be eliminated after performing the “Remedial actions” contact the

customer service of the manufacturer since all follow-up troubleshooting can only be

performed by specially trained and qualified service staff.

Fault Possible cause Remedial action

Truck does

not move

– Battery connector not con-

nected.

– Master switch (emergency

stop) depressed.

– Key switch in position “0”.

– Battery exhausted.

– Safety barrier open.

– “Two-hand operation” key

not pressed (o).

– Deadman key not pressed.

– Fuse defective.

– Check the battery connector and con-

nect if necessary.

– Release the master switch.

– Set the key switch to position “I”.

– Check the charging condition of the

battery and recharge if necessary.

– Close the safety barriers on both si-

des of the driver stand platform.

– Press the “Two-hand operation” key

(o).

– Press the deadman key.

– Check fuses F1 and 1F1.

Load

cannot be

lifted

– Truck not operative.

– Hydraulic oil level too low.

– Safety barrier open.

– “Two-hand operation” key

not pressed (o).

– Battery discharge monitor

has switched off the lifting

function.

– Fuse defective.

– Load is too heavy.

– Perform all remedial actions listed un-

der the fault “Truck does not move”.

– Check the hydraulic oil level.

– Close the safety barriers on both si-

des of the driver stand platform.

– Press the “Two-hand operation” key

(o).

– Recharge the battery.

– Check fuses 2F1 and 2F2 (o ).

– Heed the maximum capacity

(see the identification plate).

E 23

0803.GB

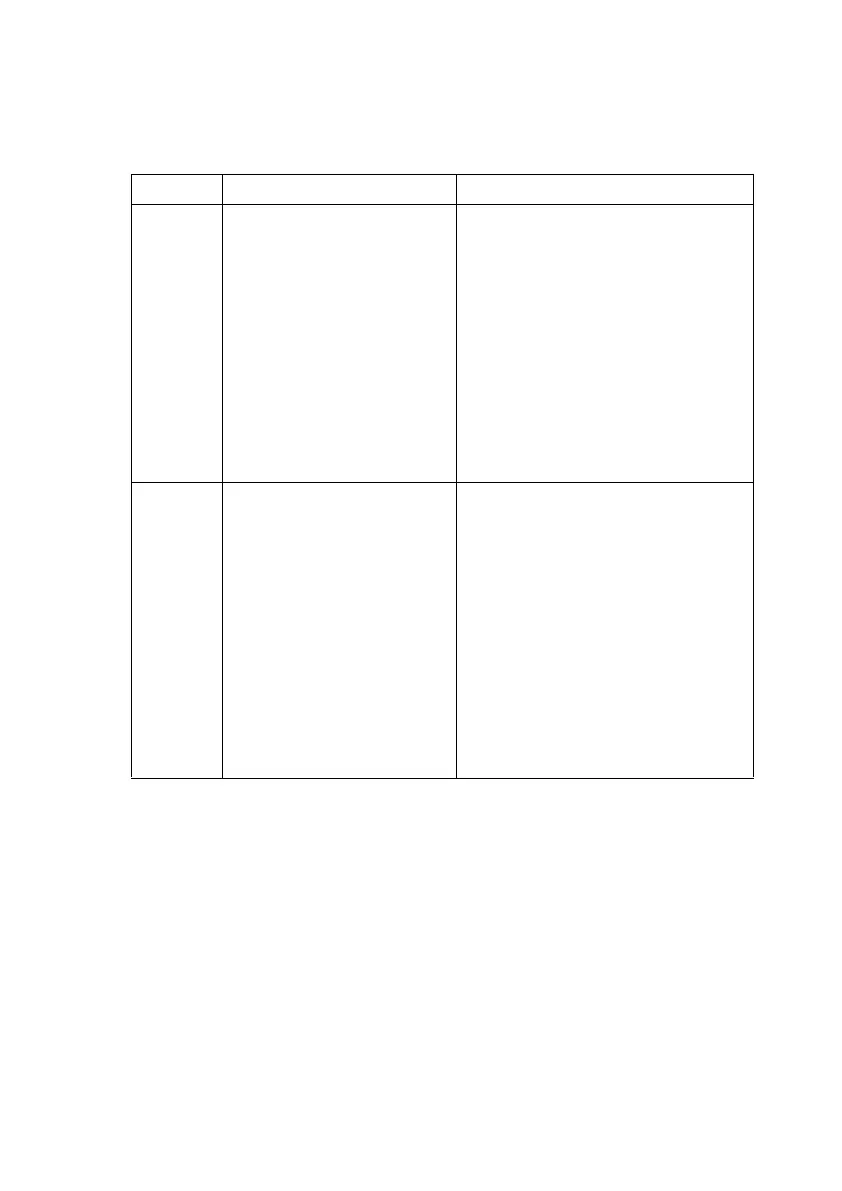

6 Fault location

This chapter enables the operator to locate and rectify minor faults and malfunctions,

or the effects of operating errors. When trying to locate a fault, proceed in the order

shown in the table.

A

If the fault could not be eliminated after performing the “Remedial actions” contact the

customer service of the manufacturer since all follow-up troubleshooting can only be

performed by specially trained and qualified service staff.

Fault Possible cause Remedial action

Truck does

not move

– Battery connector not con-

nected.

– Master switch (emergency

stop) depressed.

– Key switch in position “0”.

– Battery exhausted.

– Safety barrier open.

– “Two-hand operation” key

not pressed (o).

– Deadman key not pressed.

– Fuse defective.

– Check the battery connector and con-

nect if necessary.

– Release the master switch.

– Set the key switch to position “I”.

– Check the charging condition of the

battery and recharge if necessary.

– Close the safety barriers on both si-

des of the driver stand platform.

– Press the “Two-hand operation” key

(o).

– Press the deadman key.

– Check fuses F1 and 1F1.

Load

cannot be

lifted

– Truck not operative.

– Hydraulic oil level too low.

– Safety barrier open.

– “Two-hand operation” key

not pressed (o).

– Battery discharge monitor

has switched off the lifting

function.

– Fuse defective.

– Load is too heavy.

– Perform all remedial actions listed un-

der the fault “Truck does not move”.

– Check the hydraulic oil level.

– Close the safety barriers on both si-

des of the driver stand platform.

– Press the “Two-hand operation” key

(o).

– Recharge the battery.

– Check fuses 2F1 and 2F2 (o ).

– Heed the maximum capacity

(see the identification plate).

Loading...

Loading...