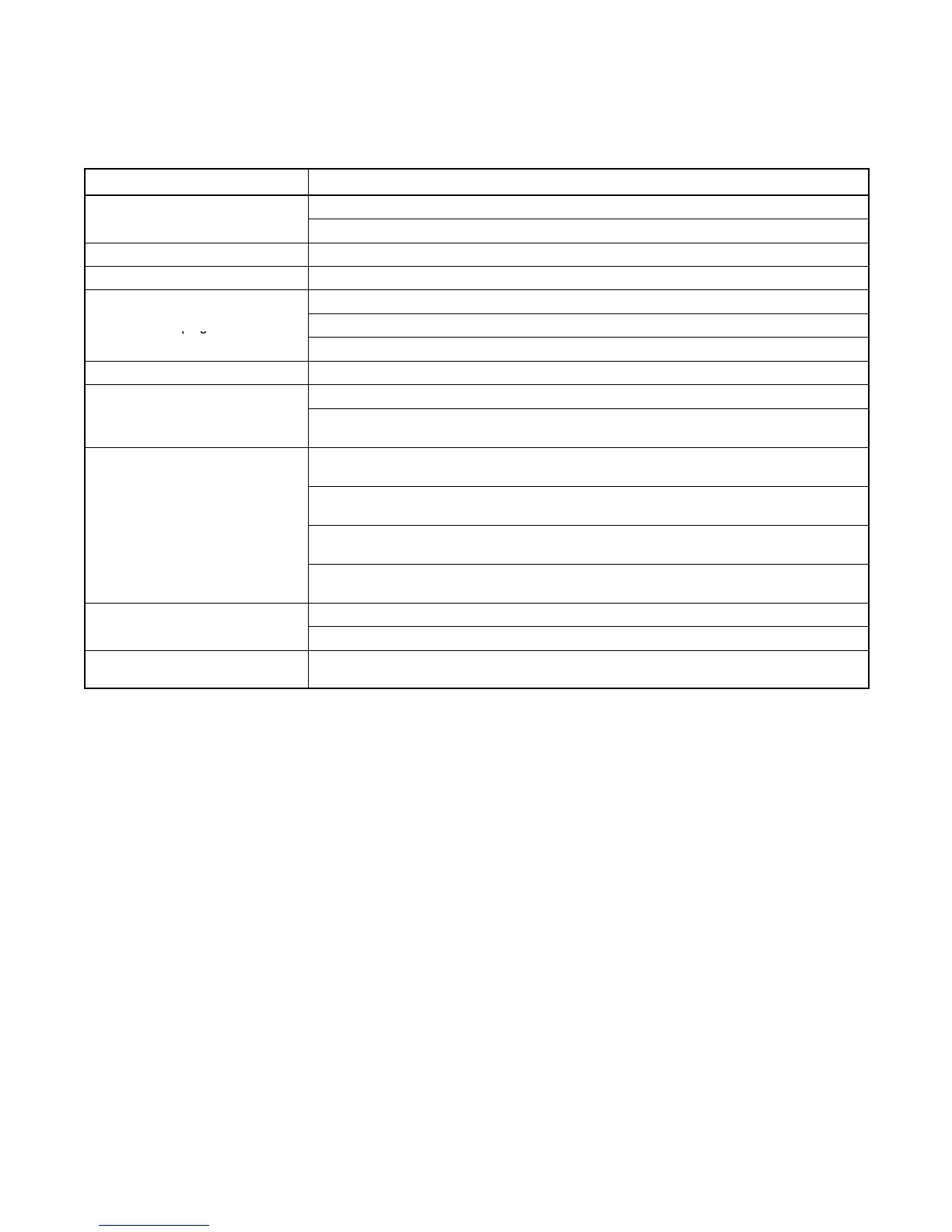

TP-5737 5/01 31Section 5 Decision-Makert 3+ Troubleshooting

5.1.2 Fault Shutdowns,

Decision-Maker 3+ Controller

If the generator set does not start or stops running

because of a fault shutdown (fault lamp lit), refer to

Figure 5-13 to identify fault conditions. Consult the

Engine Service Manual for detailed information on

correcting engine-related faults. To reset the set after a

fault shutdown, see Section 2, Operation.

Indicator Fault Condition/Causes

Hi

hen

ine tem

erature lam

Engine coolant temperature is above shutdown range; see Section 1, Specifications

lights

Cooling system malfunction

Low oil pressure lamp lights Engine oil pressure is below shutdown range, see Section 1, Specifications

Overspeed lamp lights Governed frequency is in excess of 70 Hz (2100 rpm)

Continuous cranking is more than 45 seconds

Overcrank lamp lights

Cyclic cranking is more than 75 seconds

Locked rotor

Overcrank lamp flashes Speed sensor signal is absent longer than one second

No AC output is present

Auxiliary lamp flashes

Battery power was reconnected or was low and then came back up again while generator

set master switch was in the RUN or AUTO position

Optional emergency stop switch is reset while the generator set master switch is in the RUN

or AUTO position

High exhaust temperature (P1-14) or auxiliary delay shutdown (P1-15) faults occur,if sensor

equipped

u

iliary lamp lights

Overvoltage, if equipped, has occurred, voltage 15% greater than nominal voltage (for

period longer than two seconds)

Activated by customer-supplied sensing device connected to auxiliary immediate shutdown

ports (P1-17 and P1-18)

Emergency stop switch is activated (local or remote)

Emergency stop, i

equipped

Emergency stop switch(es) are disconnected from controller terminals TB1-1 or 1A

Multiple lamps light (where

illumination may appear dim)

Main circuit board F1 (3-amp) fuse blown. F1 fuse supplies battery voltage to a remote

annunciator and/or dry contact kit.

Figure 5 -13 Fault Shutdown Troubleshooting Chart

Loading...

Loading...