4.3

Section 4

Air Cleaner and Air Intake System

4

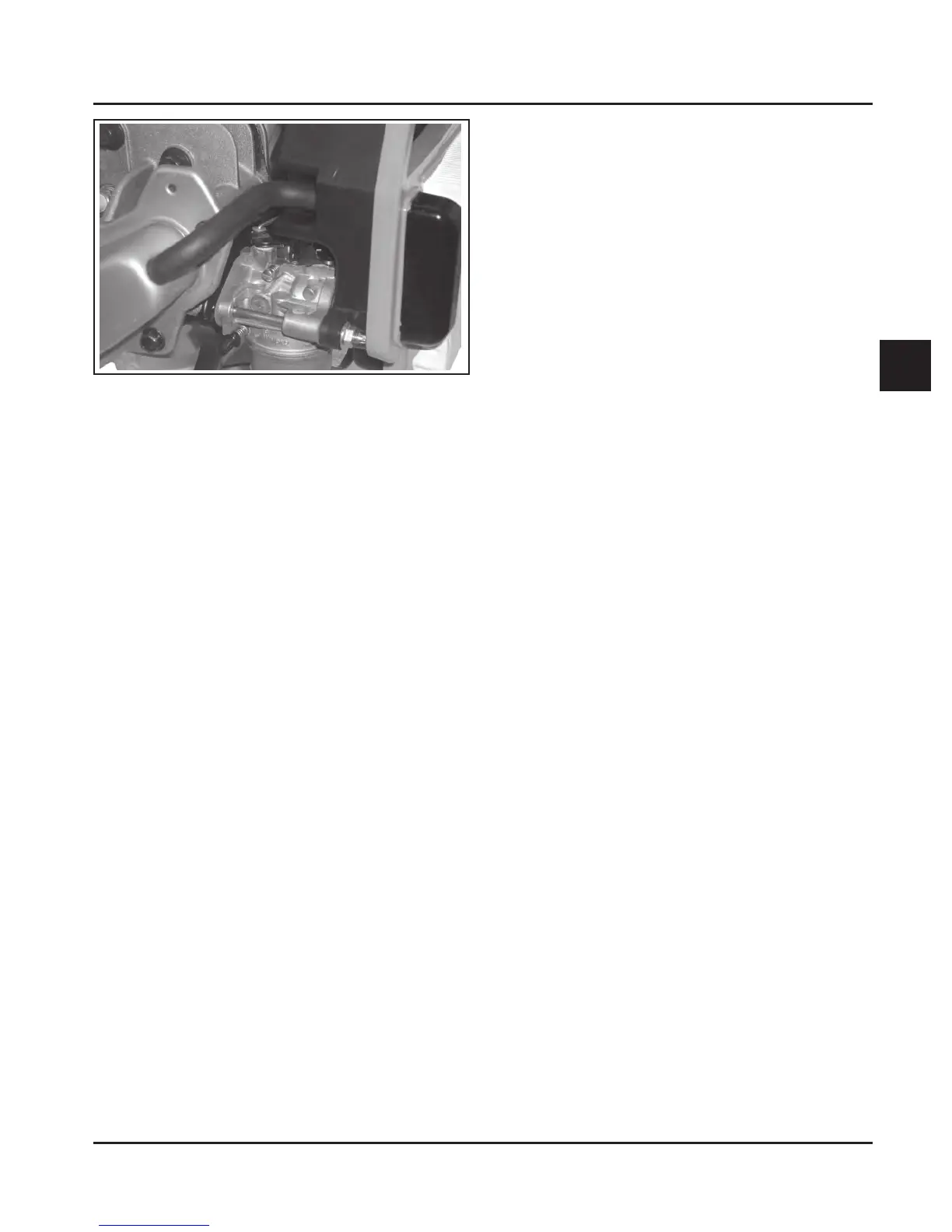

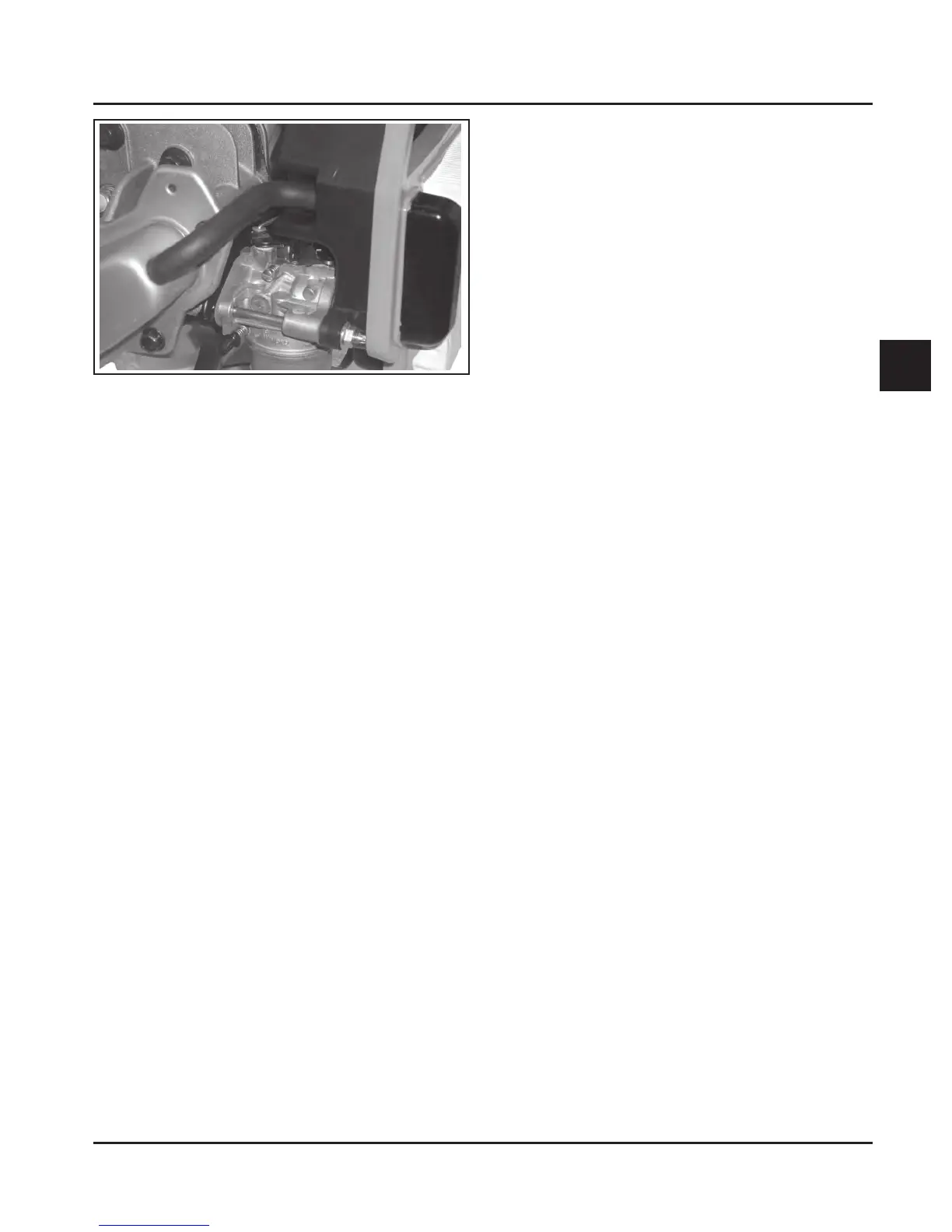

Figure 4-3. Breather Hose.

Disassembly

The following procedure is for complete disassembly

of all air cleaner components. As the removal of the air

cleaner base also affects carburetor mounting and

governor adjustment, steps 3 and 4 should only be

performed if required. Detailed photos are provided in

Sections 5, 8, and 10 for the various individual steps.

1. Loosen the air cleaner cover retaining knobs and

remove the air cleaner cover.

2. Remove the foam precleaner (if so equipped),

and the air cleaner element with formed rubber

seal.

3. Disconnect the breather hose from the valve

cover or air cleaner base.

NOTE: The air cleaner base should be removed

only if necessary.

4. Remove the two hex. flange nuts from the

mounting studs. If one stud and one thread

forming screw is used; first remove the thread

forming screw on the right side of the carburetor

inlet, which secures the air cleaner base,

carburetor and gaskets. Insert a 3/16” diameter

rod approximately 4” long, into the hole to serve

as a temporary alignment pin. Be careful not to

force the rod or damage the threads. Then

remove the hex. flange nut from the stud on the

left side of the carburetor inlet. Carefully remove

the air cleaner base and gasket. The cover

mounting studs thread into the air cleaner base,

and they should only be removed if necessary.

Reassembly

The following procedure is for complete assembly of

all air cleaner components. Steps 1-3 are necessary

only if the air cleaner base and/or the cover mounting

studs were removed in “Disassembly”.

1. Install the mounting studs into the air cleaner

base if removed previously. Tighten the studs until

bottomed, or to the end of threads (do not force).

2. Install the air cleaner base gasket and air cleaner

base, with the two metal spacers, onto the

mounting stud(s) and/or alignment pin. Make sure

the upper mounting tab is located above the

closure plate. Install and finger tighten the hex.

flange nut(s). When a long M6 thread forming

mounting screw is used, apply hand pressure to

keep the parts from shifting, then remove the

alignment pin and install the M6 thread forming

screw. DO NOT OIL. Torque the nut(s) to 5.5 N·m

(48 in. lb.). Torque the screw to 8.0 N·m

(70 in. lb.) into a new hole, or 5.5 N·m (48 in. lb.)

into a used hole, do not over tighten.

3. Reconnect the breather hose and perform the

governor adjustment (See Section 5, “Initial

Governor Adjustment”).

4. Install the air cleaner element with the pleated

side “out” and seat the rubber seal onto the edges

of the air cleaner base.

5. Install the serviced precleaner (if so equipped)

into the air cleaner cover. Make sure the hole in

the precleaner is aligned with the upper mounting

knob.

6. Reinstall the air cleaner cover and secure with the

two knobs.

Not For Resale

www.SmallEngineDiscount.com

Loading...

Loading...