Appendix

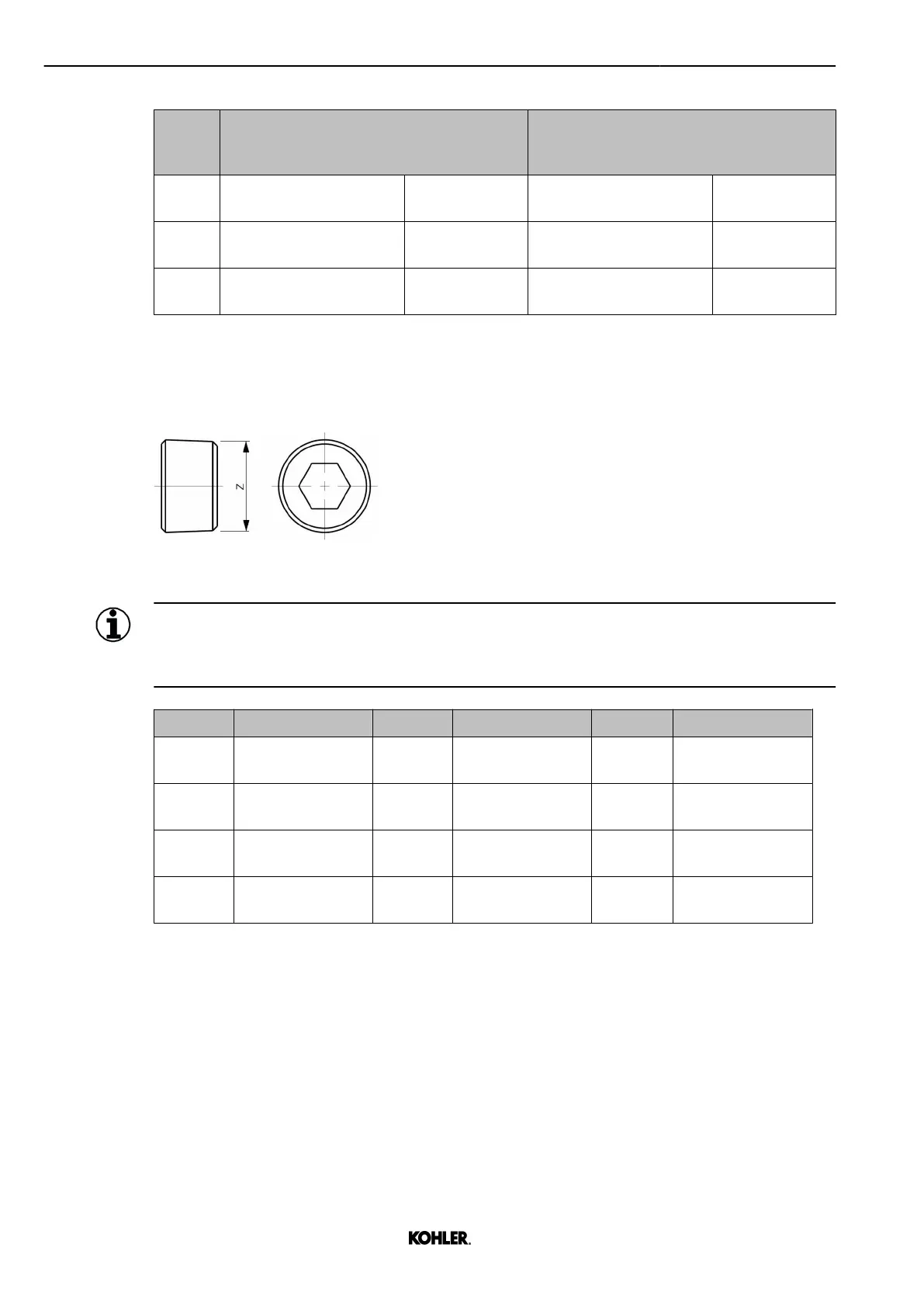

Standard tightening torques

Thread

diam‐

eter

Quality class 8.8 Quality class 10.9

M20 320 Nm

236 ft-lb

358 Nm

264 ft-lb

470 Nm

347 ft-lb

525 Nm

387 ft-lb

M24 550 Nm

406 ft-lb

- 800 Nm

590 ft-lb

-

M30 1100 Nm

811 ft-lb

- 1600 Nm

1,180 ft-lb

-

Tab. 57: Standard torques for hexagonal / socket / flange screws and hexagonal / flange nuts,

with coating without lubricant

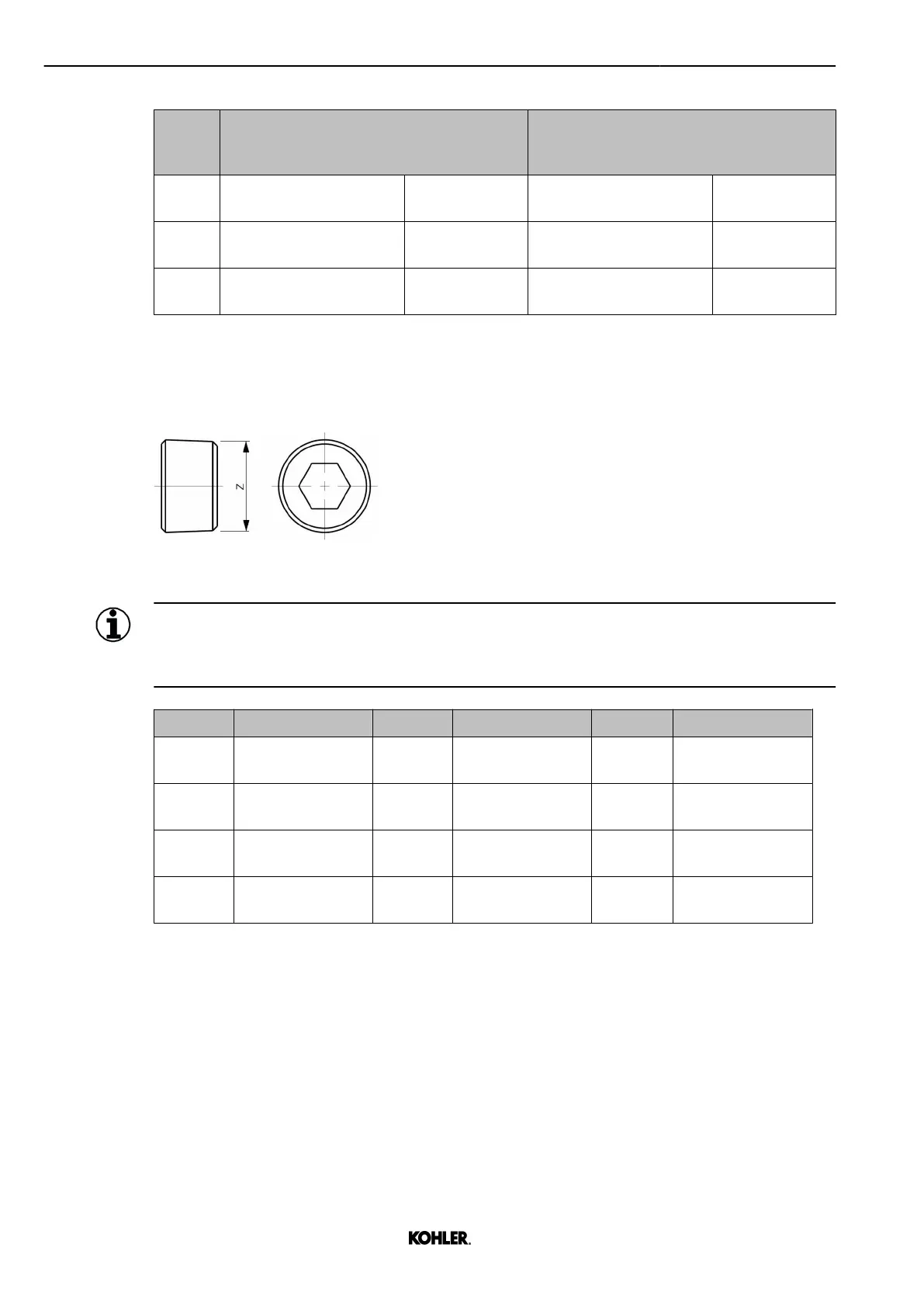

5.3.4 Standard torques for internal drive pipe plug with conical thread

Fig. 319: Internal drive pipe plug with conical thread DIN 906

Information

Tolerances of the indicated tightening torques: 10%.

Always lubricate the thread before tightening these parts (engine oil).

Thread Tightening torque Thread Tightening torque Thread Tightening torque

M 6 x 1 5 Nm

4 ft-lb

1)

M 14 x 1.5 57 Nm

42 ft-lb

M 20 x 1.5 98 Nm

72 ft-lb

M 8 x 1 12 Nm

9 ft-lb

M 16 x 1.5 68 Nm

50 ft-lb

M 36 x 1.5 280 Nm

207 ft-lb

M 10 x 1 18 Nm

13 ft-lb

M 18 x 1.5 87 Nm

64 ft-lb

M 48 x 1.5 280 Nm

207 ft-lb

M 12 x 1.5 30 Nm

22 ft-lb

- - - -

Tab. 58: Standard torques for internal drive pipe plug with conical thread

1)

Special tolerance: +0.5 mm (0.02 in)

5.3.5 Standard torques for screws according to DIN 7643, DIN 910, DIN

908

With copper sealing ring according to DIN 7603, for:

– Hollow screw for ring-type banjos according to DIN 7643

– Hexagon head screw plugs with collar - Cylindrical thread according to DIN 910

– Internal drive screw plugs with collar - Cylindrical thread according to DIN 908

272

© 2022 by Kohler Co. All rights reserved.

KD62V12 33525088601_8_1 EN_US

2022-09

Loading...

Loading...